Method for growing bismuth selenide high-index surface single crystal thin film on silicon (211) substrate

A single-crystal thin-film, high-index technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of incompatibility and poor economy, and achieve the effects of good compatibility, simple process and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

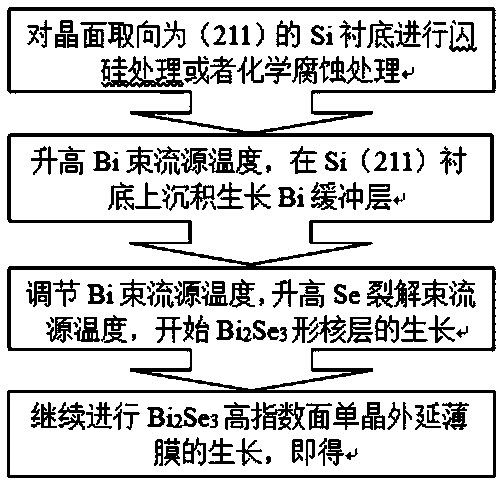

[0041] like figure 1 Shown, the present invention is a kind of method for growing bismuth selenide high-index plane monocrystalline thin film on silicon (211) substrate, comprises the following operation steps:

[0042] Step 1): After placing the Si(211) substrate in an ultra-high vacuum molecular beam epitaxy system, heat it to 500°C for degassing for 12 hours until the background vacuum reaches 5×10 -10 On the order of mbar, continue heating the Si(211) substrate to 1250° C. for 10 seconds, and then lower the temperature to 250° C.

[0043] Step 2): Raise the temperature of the Bi beam source until the equivalent pressure of the Bi beam reaches 3×10 -8 mbar, open the Bi beam source baffle to start growing the Bi buffer layer, the growth time of the Bi buffer layer is 6min, and the growth thickness is

[0044] Step 3): Close the Bi beam source baffle to end the growth of the Bi buffer layer, lower the temperature of the Si(211) substrate to 100°C, and adjust the temperatu...

Embodiment 2

[0051] like figure 1 Shown, the present invention is a kind of method for growing bismuth selenide high-index plane monocrystalline thin film on silicon (211) substrate, comprises the following operation steps:

[0052] Step 1): Before placing the Si(211) substrate in the ultra-high vacuum molecular beam epitaxy system, etch it with 40% HF solution for 2-5 minutes, then rinse it with deionized water and blow it with high-purity nitrogen After drying, the substrate was placed in an ultra-high vacuum molecular beam epitaxy system, heated to 400 ° C for 12 hours, and the background vacuum reached 5 × 10 -10 On the order of mbar, continue heating the Si(211) substrate to 850°C for 10 seconds, and then lower the temperature to 250°C.

[0053] Step 2): Raise the temperature of the Bi beam source until the equivalent pressure of the Bi beam reaches 1×10 -7 mbar, open the Bi beam source baffle to start growing the Bi buffer layer, the growth time of the Bi buffer layer is 2min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com