Preparation method of medicine residue fiber material

A fiber material and drug residue technology, which is applied in the field of preparation of drug residue fiber materials, can solve the problems of good performance, low pulp whiteness, and difficulty in removing lignin macromolecular structure, etc., and achieves enhanced fiber crosslinking and physical properties. enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

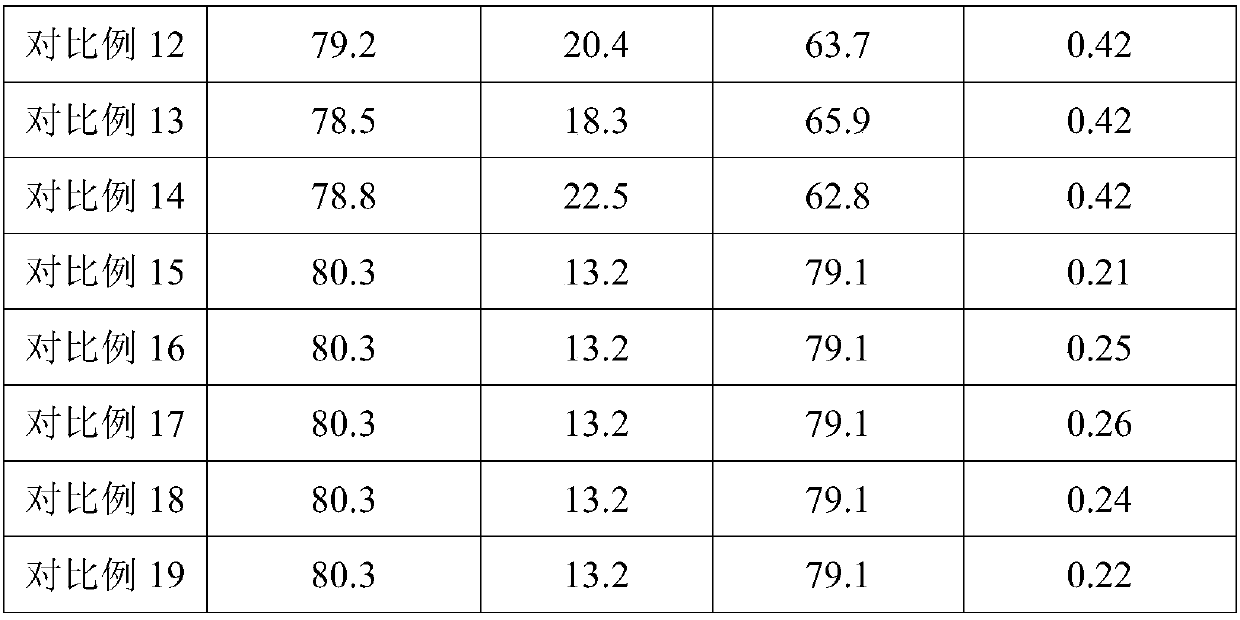

Examples

Embodiment 1

[0036] This embodiment provides a method for preparing a medicinal dregs fiber material, and the specific operation steps are as follows:

[0037] S1. Pretreatment: put Qianjinfang medicine dregs with a water content of 25% in the fermentation tank, add 2 kg / ton of biological compound enzymes, stir evenly, and use microwave radiation to process under aerobic conditions. The microwave power is 1000W, microwave time is 200min, ferment the Qianjinfang medicine dregs material, and filter after fermentation to obtain filtrate and filtrate;

[0038] The preparation method of the above Qianjin Recipe dregs refers to the patent ZL99115682.X, a manufacturing process of Fuke Qianjin Capsules; Or the mixture of medicinal dregs after ethanol extraction. The particle size of Qianjin Fang medicine dregs is less than 3cm.

[0039] The biological complex enzyme is prepared from the following raw materials in weight percentage: 6% of white rot fungus, 20% of P. chrysosporium, 24% of xylanase...

Embodiment 2

[0044] This embodiment provides a method for preparing a medicinal dregs fiber material, and the specific operation steps are as follows:

[0045] S1. Pretreatment: put Qianjinfang medicine dregs with a water content of 45% in the fermentation tank, add 4 kg / ton of biological compound enzymes, stir evenly, and treat with microwave radiation under aerobic conditions. The microwave power is 1500W, microwave time of 100min, ferment the Qianjinfang medicine dregs, and filter after fermentation to obtain filtrate and filtrate;

[0046] For the preparation method of the above Qianjin Recipe dregs, refer to the patent ZL98112696.0, the preparation method of Fuke Qianjin Tablets, a compound Chinese medicine preparation; Medicinal residue mixture after water or ethanol extraction. The particle size of Qianjin Fang medicine dregs is less than 2cm.

[0047] The biological complex enzyme is prepared from the following raw materials in weight percentage: 12% of white rot fungus, 12% of P...

Embodiment 3

[0052] This embodiment provides a method for preparing a medicinal dregs fiber material, and the specific operation steps are as follows:

[0053] S1. Pretreatment: put Qianjinfang medicine dregs with a water content of 35% in a fermentation tank, add 3 kg / ton of biological compound enzymes, stir evenly, and treat with microwave radiation under aerobic conditions. The microwave power is 1200W, microwave time of 120min, ferment the Qianjinfang medicine dregs, and filter after fermentation to obtain filtrate and filtrate;

[0054] For the preparation method of the above-mentioned Qianjin Recipe dregs, refer to the manufacturing method of the patent ZL99115683.8, a kind of Fuke Qianjin Capsule; Or the mixture of dregs after ethanol extraction. The particle size of Qianjin Fang medicine dregs is less than 2.5cm.

[0055] The biological complex enzyme is prepared from the following raw materials in weight percentage: 8% of white rot fungus, 18% of P. chrysosporium, 26% of xylanas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com