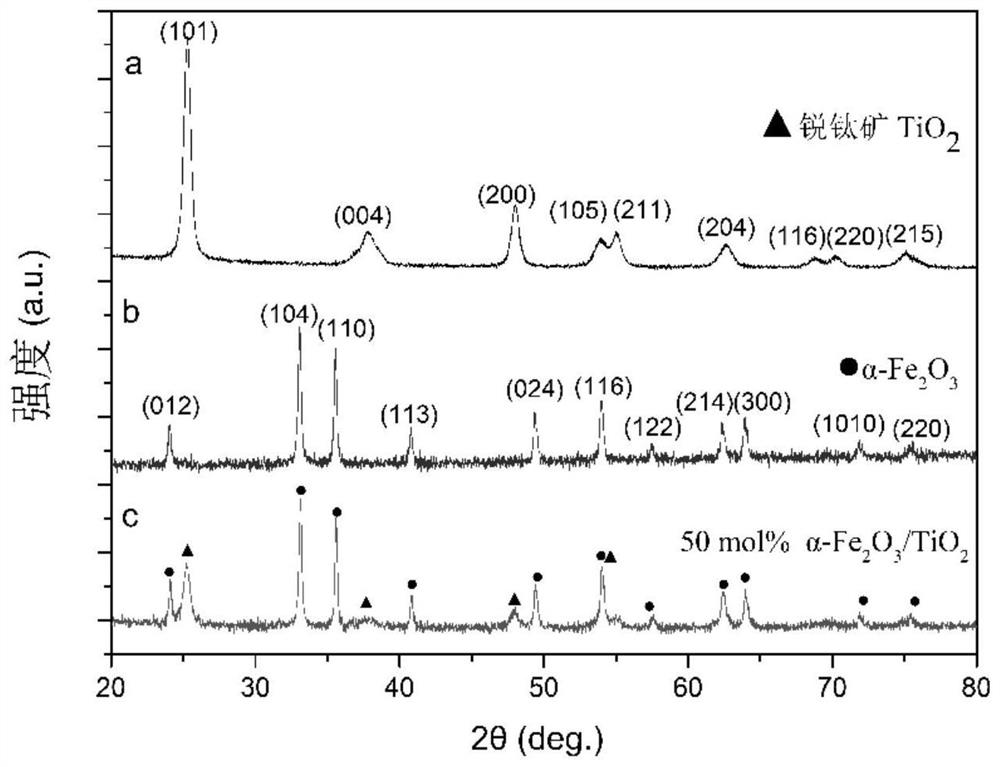

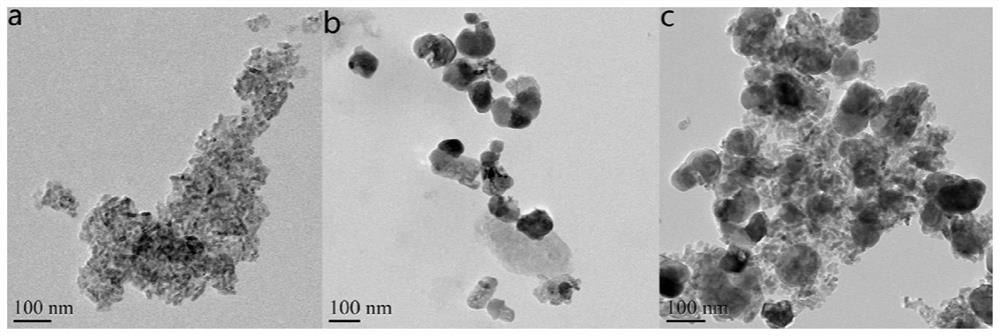

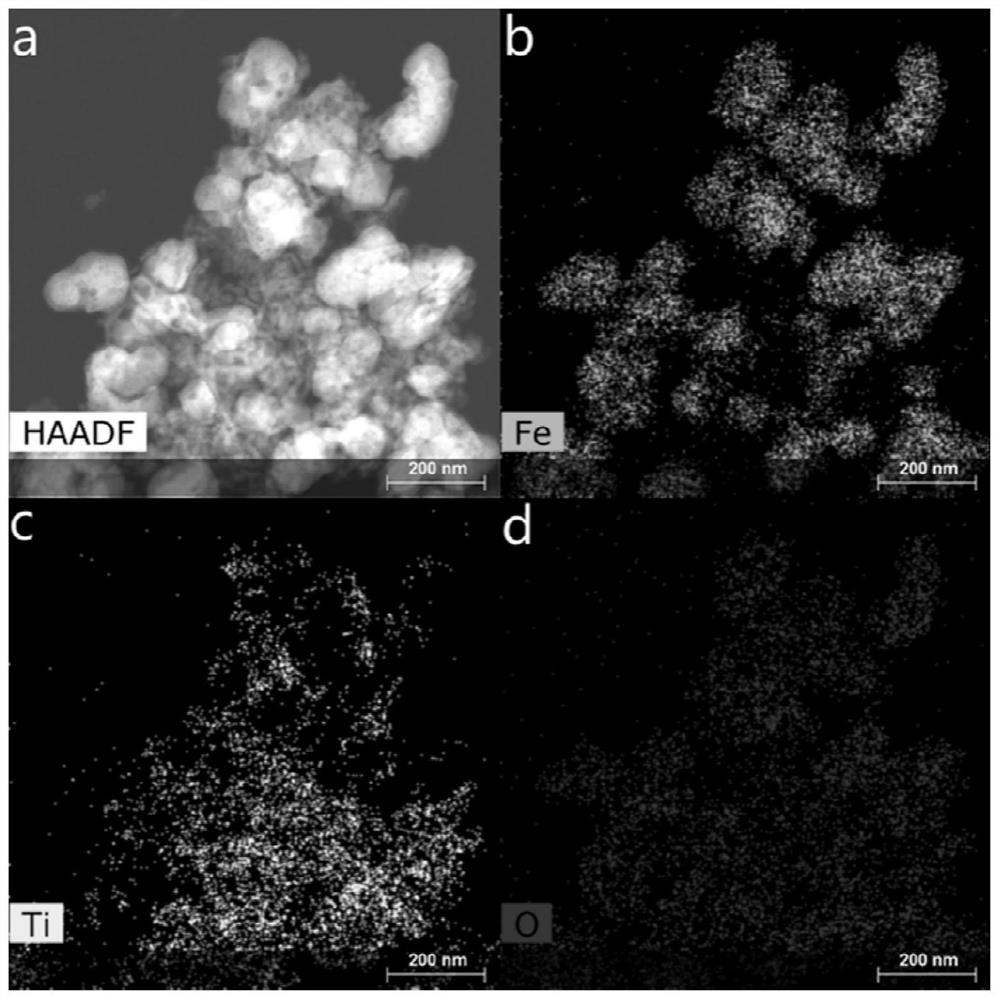

an α-fe 2 o 3 /tio 2 Nanocomposites and their preparation h 2 s gas sensor

A nano-composite material and gas sensor technology, applied in the field of H2S gas sensor, can solve the problems of high price, unsatisfactory reliability, and high working temperature of the sensor, reduce working energy consumption, large market development prospects, and good dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] (1) Take 12.1206g of ferric nitrate nonahydrate, add 300mL of distilled water to dissolve, and make 0.1mol / L ferric nitrate solution, pour the solution into a 1L flask, and then heat it with an oil bath, the temperature is controlled at about 85°C . Then take 3.997g of sodium hydroxide, add 100mL of distilled water to dissolve to make 1mol / L sodium hydroxide solution, and heat it to boiling, then quickly add it to the heated ferric nitrate solution, and use a magnetic stirrer at 700r / min Stir for 10 min. Then take 2.1198g of sodium carbonate, add 100mL of distilled water to dissolve, make 0.2mol / L sodium carbonate solution, and heat to boiling, then quickly add to the heated ferric nitrate solution, and stir at 700r / min with a magnetic stirrer 10min. Subsequently, the mixture solution was centrifuged at 5000r / min for 10min to separate the resulting brown Fe(OH) 3 , and centrifuged three times with distilled water to remove excess nitrate ions. The washed Fe(OH) 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com