Perovskite solar cell introduced with organic ligand, and preparation method of perovskite solar cell

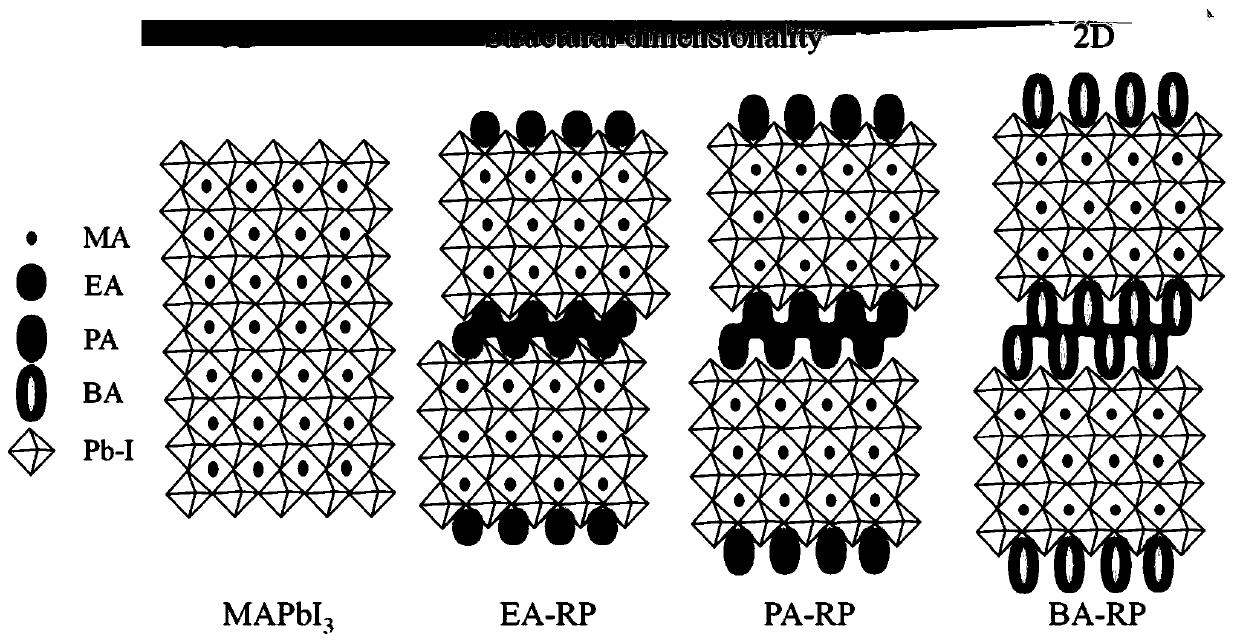

A technology of organic ligands and solar cells, applied in the field of solar photovoltaic, can solve the problems of reducing the photoelectric conversion efficiency of devices, reducing the absorption coefficient and carrier transport capacity of perovskite materials, and achieving the effect of facilitating temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

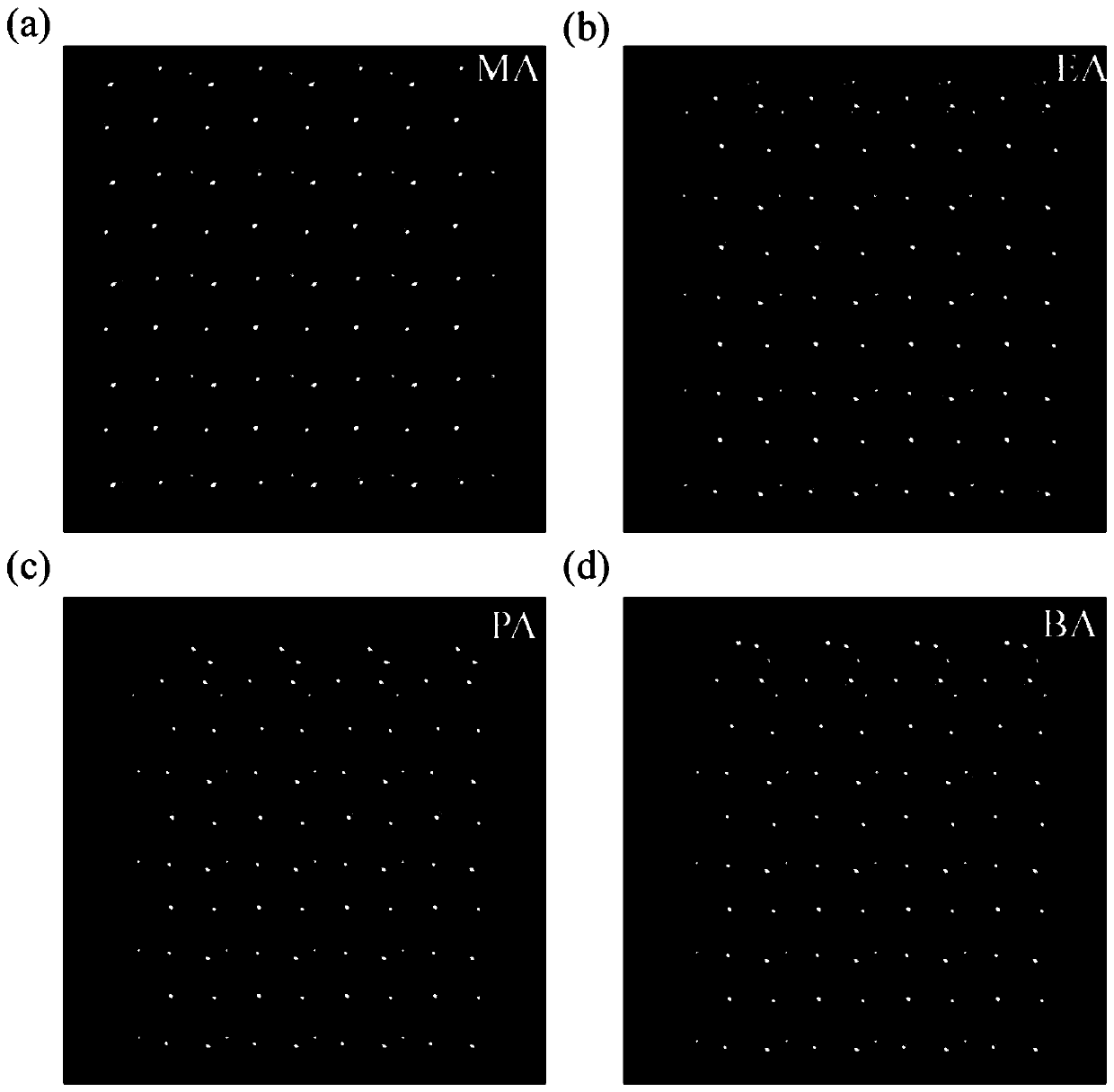

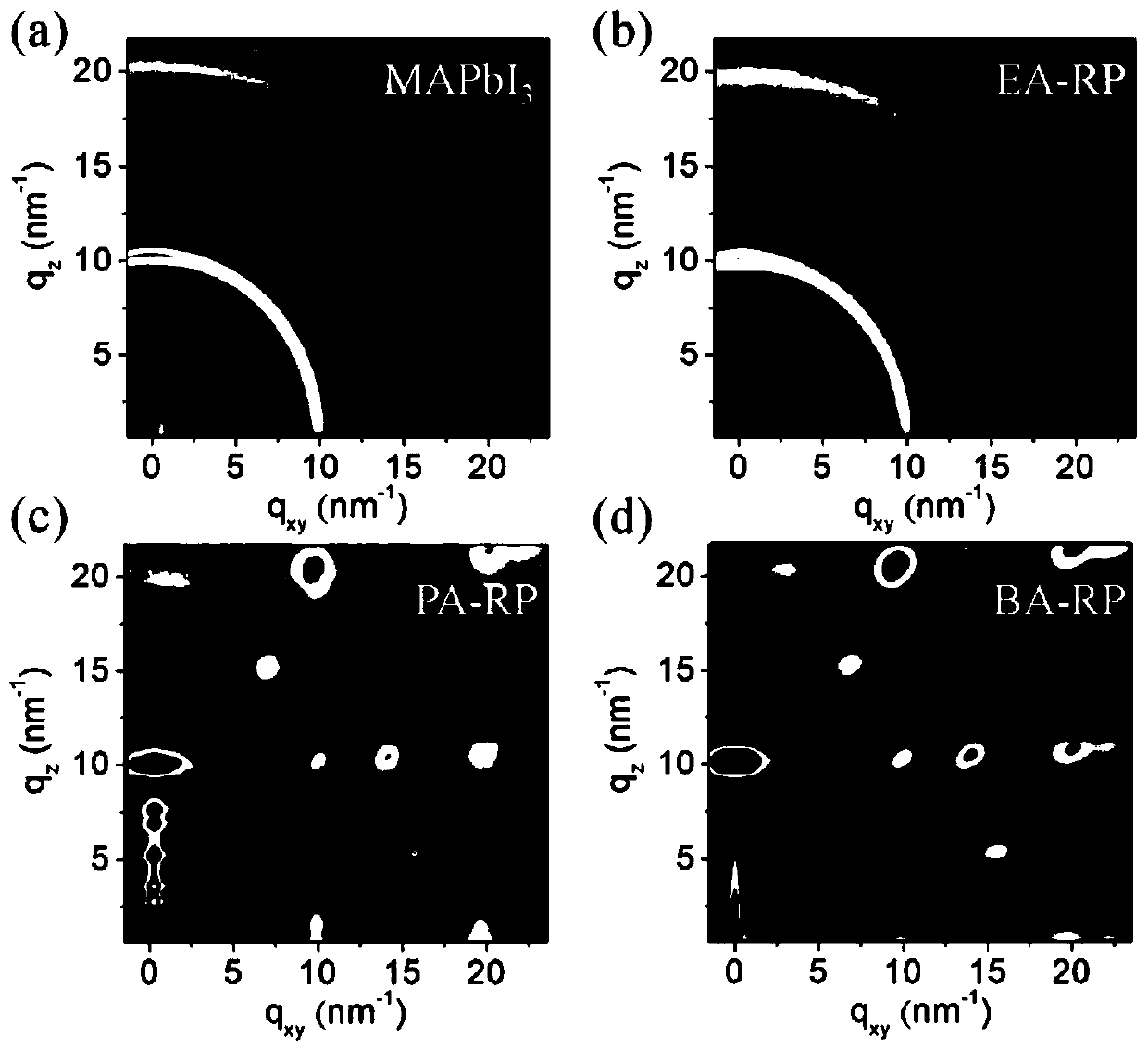

Embodiment 1

[0075] S1. Preparation of perovskite precursor solution: PbI with a mixing molar ratio of 1.2:0.9:0.6 2 , MAI and EAI are used as solutes, and DMSO and DMF with a mixing volume ratio of 7:3 are used as solvents; the solutes are dissolved in the mixed solvent at a concentration of 1.2mol / L to obtain a mixed solution; the mixed solution is stirred evenly at 60°C, The stirring speed is 600r / s, and the clarified perovskite solution is obtained by filtering with a polytetrafluoroethylene filter membrane with a pore size of 0.45 μm, which is the perovskite precursor solution;

[0076] S2. Clean the FTO glass substrate: take 2.5×2.5cm 2 Fluorine-doped SnO 2 (FTO) transparent conductive glass, use acetone, isopropanol, ethanol and ultrapure water to ultrasonically clean, and the cleaning time of each type of cleaning solution is >20min; dry the cleaned glass substrate with a nitrogen gun, and place it in a container for use ;

[0077] S3, preparing TiO 2 Electron transport layer: ...

Embodiment 2

[0085] S1. Preparation of perovskite precursor solution: PbI with a mixing molar ratio of 1.2:0.9:0.6 2 , MAI and PAI as the solute, and DMSO and DMF with a mixing volume ratio of 7:3 as the solvent; the solute is dissolved in the mixed solvent at a concentration of 1.2mol / L to obtain a mixed solution; the mixed solution is stirred evenly at 60°C, The stirring speed is 600r / s, and the clarified perovskite solution is obtained by filtering with a polytetrafluoroethylene filter membrane with a pore size of 0.45 μm, which is the perovskite precursor solution;

[0086] S2, cleaning the FTO glass substrate: same as S2 in Example 1;

[0087] S3, preparing TiO 2 Electron transport layer: same as S3 in Example 1;

[0088] S4, preparation of perovskite absorbing layer: same as S4 in Example 1;

[0089] S5, preparation of Spiro-OMeTAD hole transport layer: same as S5 in Example 1;

[0090] S6, Au electrode evaporation: same as S6 in Example 1;

Embodiment 3

[0092] S1. Preparation of perovskite precursor solution: PbI with a mixing molar ratio of 1.2:0.9:0.6 2 , MAI and BAI as solute, mixed volume ratio is 7:3 DMSO and DMF as solvent; It is 1.2mol / L that solute is dissolved in mixed solvent according to concentration, obtains mixed solution; All the other steps are with S1 among the embodiment 2;

[0093] S2, cleaning the FTO glass substrate: same as S2 in Example 1;

[0094] S3, preparing TiO 2 Electron transport layer: same as S3 in Example 1;

[0095] S4, preparation of perovskite absorbing layer: same as S4 in Example 1

[0096] S5, preparation of Spiro-OMeTAD hole transport layer: same as S5 in Example 1

[0097] S6, Au electrode evaporation: the same as S6 in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com