Lithium Ion Solid State Electrolyte Film and Its Application

A technology of solid electrolyte and lithium ion, which is applied in circuits, fuel cells, electrical components, etc., can solve problems such as insufficient solid electrolyte film density, adverse effects on lithium battery performance, and unfavorable lithium uniform deposition, achieving high current stability Charge-discharge cycle, large-scale batch production, simple and environmentally friendly preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

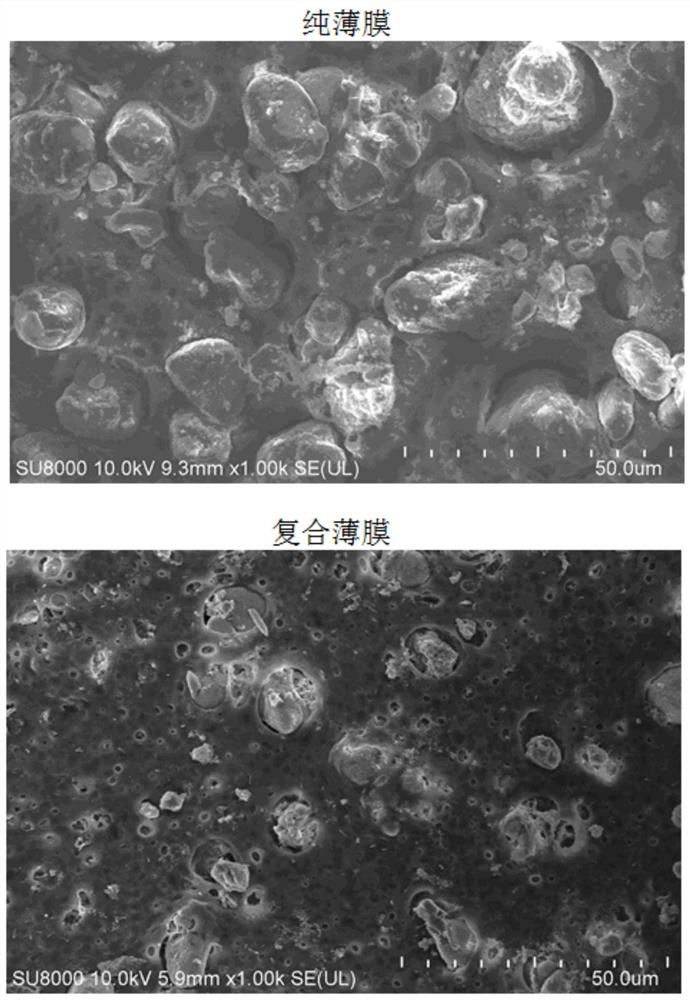

[0043] Accurately weigh 2.5 g of polyethersulfone powder (PESf) and 30 ml of N,N-dimethylpyrrolidone (NMP) into an agate ball mill jar, seal and let stand for 15 minutes to obtain a homogeneous polymer solution, and then add 25 g of Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 (LATP) solid electrolyte powder, sealed and quickly ball milled for 3 hours to obtain a uniform viscous slurry, then transferred to a vacuum oven at room temperature for 3 minutes to remove the air bubbles in the mixed slurry, and then used a coating machine to coat the mixed slurry at a speed of 5m / min (Casting film slurry) evenly coated on the aluminum foil, spray 5mL deionized water evenly on the aluminum foil with an airbrush for pre-curing, then soak it in 50mL deionized water, take it out after 12h, wash and dry with alcohol Obtain the LATP lithium-ion solid-state electrolyte base film separated from the aluminum foil, which is called a pure film in the accompanying drawings, and the following examples are t...

Embodiment 2

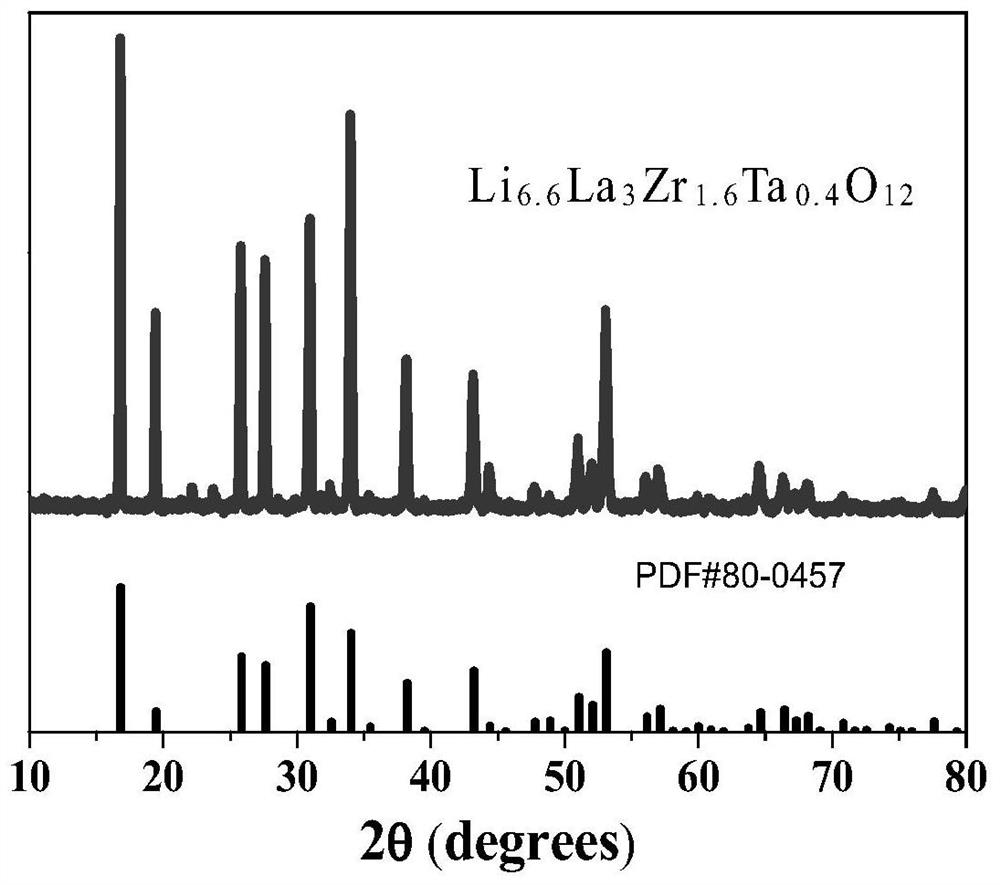

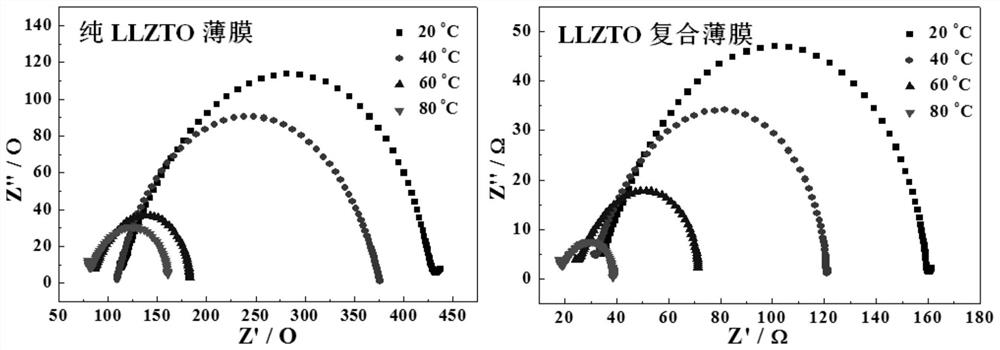

[0047] Accurately weigh 4 g of polyethersulfone powder (PESf) and 45 ml of N, N-dimethylpyrrolidone (NMP) into an agate ball mill jar, seal and let stand for 15 minutes to obtain a homogeneous polymer solution, and then add 30 g of Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 (LLZTO) solid electrolyte powder, sealed and quickly ball milled for 3 hours to obtain a uniform viscous slurry, then transferred to a vacuum oven at room temperature for 3 minutes to remove the air bubbles in the mixed slurry, and then used a coating machine to coat the mixed slurry at a speed of 5m / min Evenly coated on the aluminum foil, use a spray pen to spray 5mL alcohol evenly on the aluminum foil for pre-curing, then soak it in 50mL deionized water, take it out after 12h, wash and dry with alcohol to get the LLZTO lithium ion solid electrolyte base membrane.

[0048] The above-mentioned LLZTO lithium-ion solid-state electrolyte base film was immersed in 5 mL of an alcohol solution of 15-crown-5 lithium iodid...

Embodiment 3

[0052] Accurately weigh 2.5 g of polyacrylonitrile powder (PAN) and 30 ml of N,N-dimethylformamide (DMF) into an agate ball mill jar, seal and let stand for 15 minutes to obtain a homogeneous polymer solution, and then add 30 g of Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 (LLZTO) solid electrolyte powder, sealed and quickly ball milled for 3 hours to obtain a uniform viscous slurry, then transferred to a room temperature vacuum oven for 3 minutes to remove the air bubbles in the mixed slurry, and then used a coating machine to coat the mixed slurry at a speed of 5m / min Apply evenly on the aluminum foil, spray 5mL of isopropanol onto the aluminum foil with an airbrush for pre-curing, then soak it in 50mL of isopropanol, take it out after 12 hours, wash and dry with alcohol to obtain a lithium-ion solid electrolyte basement membrane.

[0053] The above-mentioned LLZTO lithium-ion solid-state electrolyte base film was immersed in an alcohol solution of 12-crown-4 lithium iodide with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com