Method and apparatus for zero-emission treatment of desulfurization wastewater

A treatment method and desulfurization wastewater technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problems of chemical dosing, large fluctuations in calcium and magnesium concentration, and high cost. problem, achieve the effect of reducing dosage, low price and reducing softening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

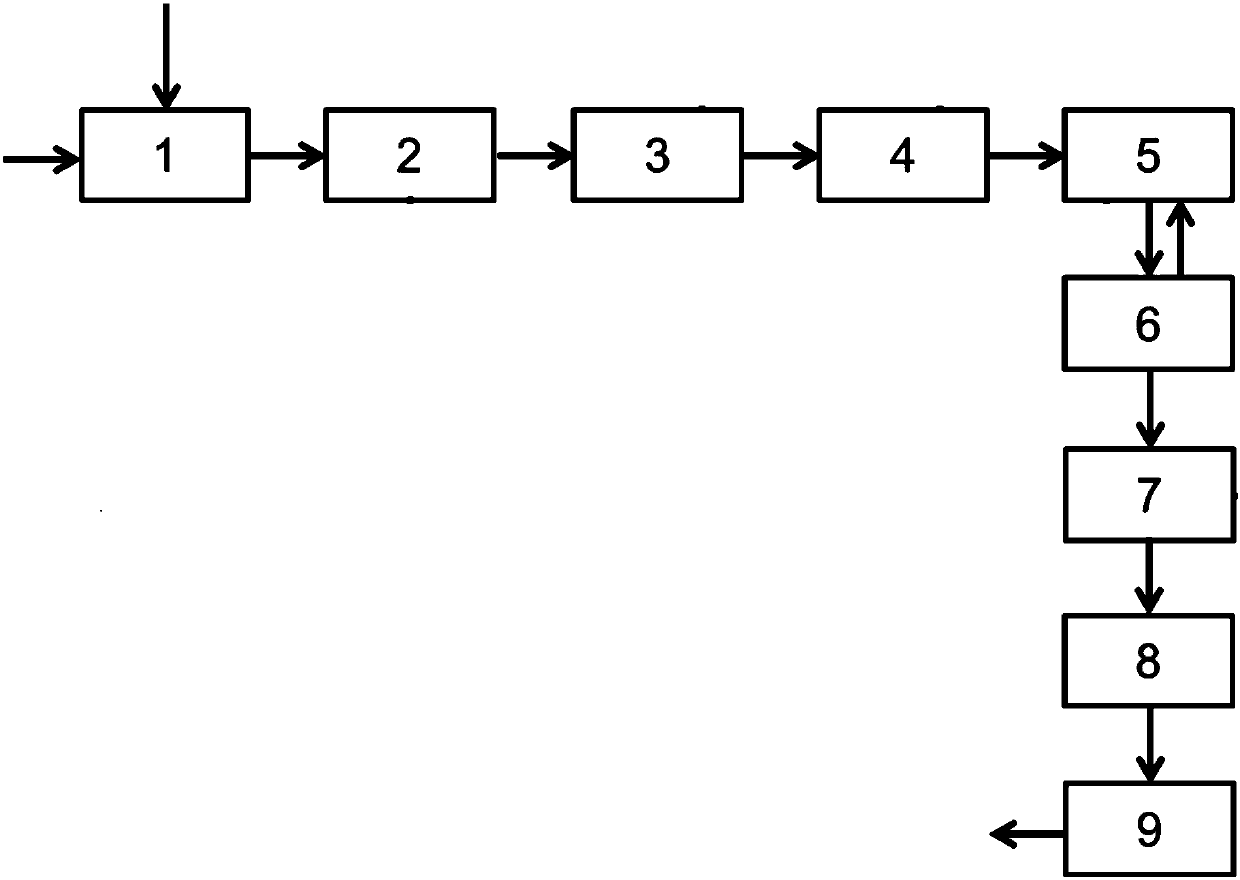

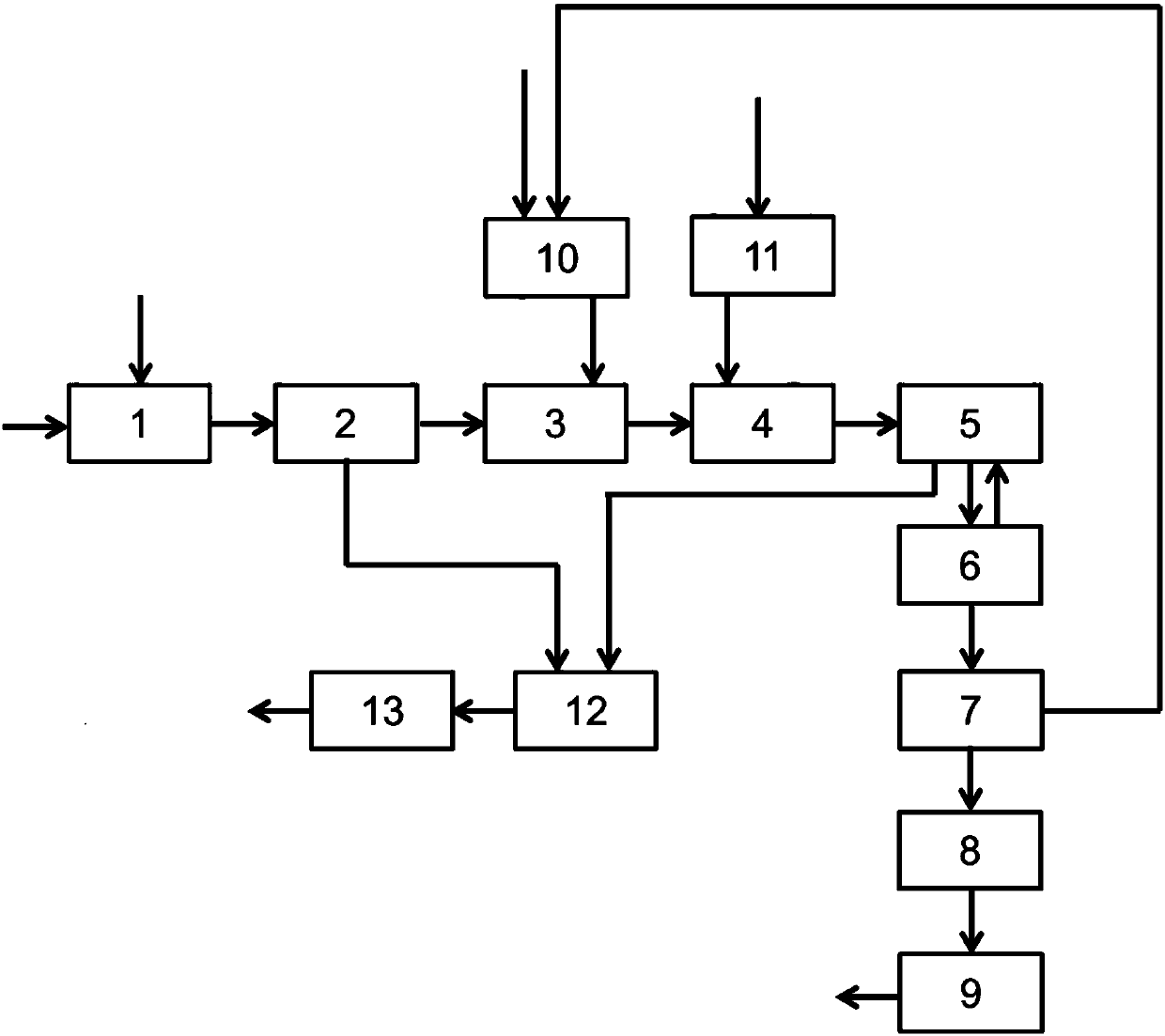

[0119] Zero discharge treatment device for desulfurization wastewater, such as figure 2 shown.

[0120] Including magnesium removal reaction box 1, sedimentation box 2, coarse decalcification box 3, fine decalcification box 4, suspended matter concentration box 5, tubular ultrafiltration device 6, nanofiltration salt separation device 7, reaction Permeation device 8, MVR evaporation crystallization device 9.

[0121] Described coarse decalcification case 3 realizes Na by sodium sulfate tracer dosing device 10 2 SO 4 Accurate dosing, the fine decalcification box 4 realizes Na 2 CO 3 Accurate dosing, the tubular ultrafiltration device 6 is connected with the suspended solids concentration box 5 through a return line, and the Na 2 SO 4 The concentrated solution is connected with the sodium sulfate tracer dosing device 10 through the return line, and the settling tank 2 and the suspended matter concentration tank 5 are connected with the sludge buffer tank 12 respectively, ...

Embodiment 2

[0130] On the basis of Example 1, a zero-discharge process for desulfurization wastewater that can reduce the consumption of softening agents is also provided, and the process is specifically described as follows:

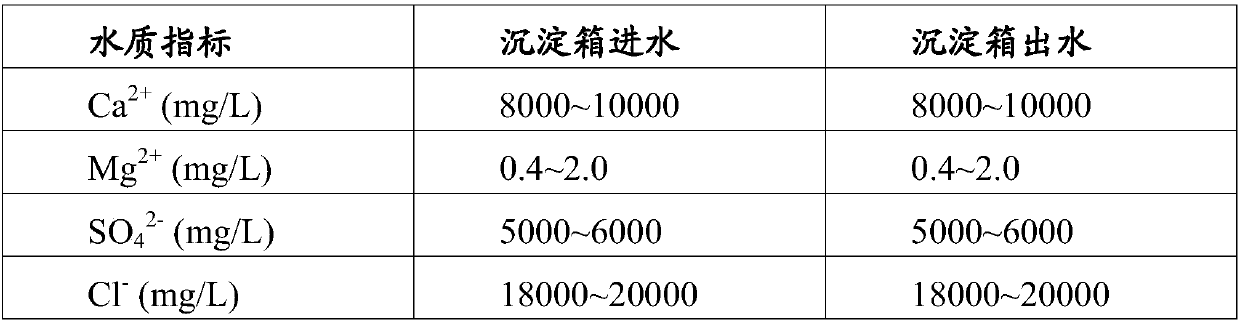

[0131] (1) The desulfurization wastewater treated by the triple box enters the magnesium removal box, and is added by adding Ca(OH) 2 Adjust the pH to above 11, the Mg in the wastewater 2+ Convert to Mg(OH) 2 The results of sedimentation, influent and effluent water quality are shown in the table below:

[0132] Table 1

[0133] water quality index

Inlet of magnesium removal reaction tank

Water out of magnesium removal reaction tank

Ca 2+ (mg / L)

7000~8000

8000~10000

Mg 2+ (mg / L)

2000~3000

0.4~2.0

SO 4 2- (mg / L)

5000~6000

5000~6000

Cl - (mg / L)

18000~20000

18000~20000

TDS(mg / L)

35000~40000

34000~39000

SS(mg / L)

50~70

28000~30000

pH

7.0

11.0~11.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com