Fluorinated polyether siloxane, preparation method and application thereof

A technology of fluorinated polyether siloxane and fluorinated polyether, which is applied in the field of polyether siloxane, and can solve the problems of poor antifouling effect, insufficient adhesion between modified silicone resin and fluorocarbon resin and substrates, etc. , to achieve the effects of good wear resistance and antifouling durability, easy control of the preparation process, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

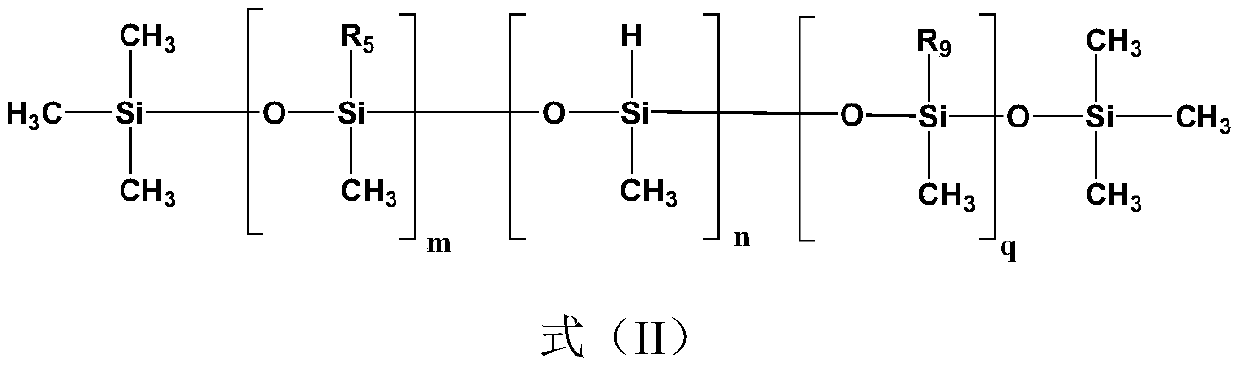

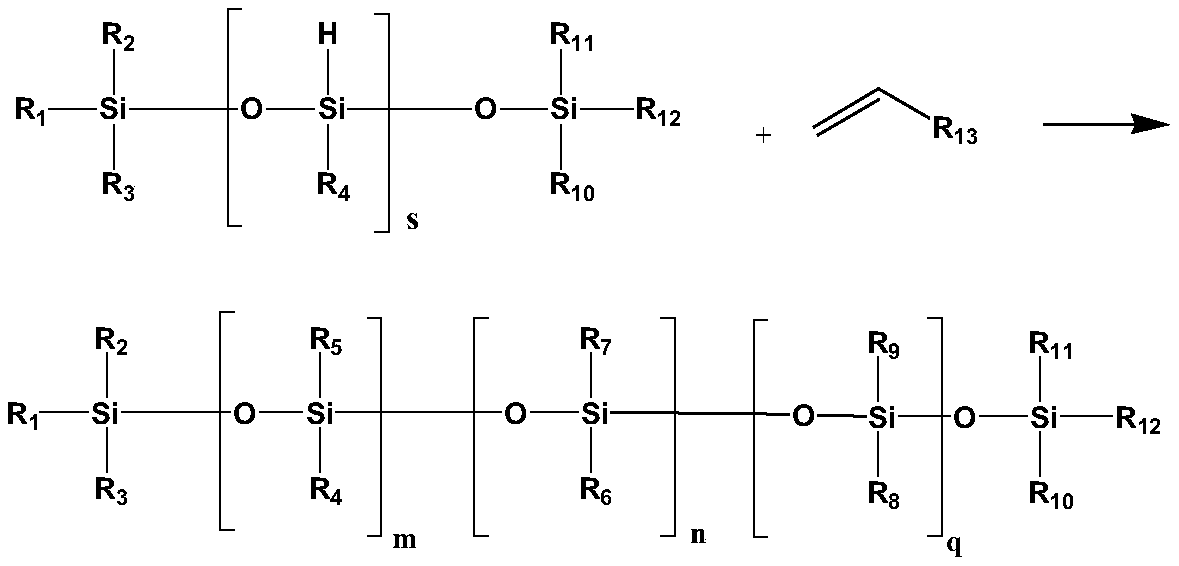

[0036]

[0037] Get 100g methyl hydrogen silicone oil (hydrogen 1.62%) and 40g CF 3 (CF 2 ) 3 CH=CH 2 In a 1L three-necked flask, add 100ml of isopropanol, place the three-necked flask in a water bath, add 8ml of isopropanol solution of chloroplatinic acid (concentration: 1g / 100ml) dropwise while stirring, and react at 60°C for 3h . Evaporate unreacted CF under reduced pressure 3 (CF 2 ) 3 CH=CH 2 monomer.

[0038] Infrared spectrum shows 1260cm -1 There is a peak (C-F), indicating that a fluorine-containing alkyl group has been inserted into the hydrogen-containing silicone oil segment, at 2200cm -1 There is a peak (Si-H), indicating that the product contains active hydrogen.

[0039] use 29 Si-NMR, 13 The resulting product was analyzed by C-NMR and had an average composition of 16 for m, 68 for n and 16 for q.

Embodiment 2

[0041]

[0042] Get 100g methyl hydrogen silicone oil (hydrogen 1.62%) and 60g CF 3 (CF 2 ) 4 CH=CH 2 In a 1L three-necked flask, add 100ml of isopropanol, place the three-necked flask in a water bath, add 10ml of isopropanol solution of chloroplatinic acid (concentration: 1g / 100ml) dropwise while stirring, and react at 40°C for 5h . Evaporate unreacted CF under reduced pressure 3 (CF 2 ) 4 CH=CH 2 monomer.

[0043] Infrared spectrum shows 1260cm -1 There is a peak (C-F), indicating that a fluorine-containing alkyl group has been inserted into the hydrogen-containing silicone oil segment, at 2200cm -1 There is a peak (Si-H), indicating that the product contains active hydrogen.

[0044] use 29 Si-NMR, 13 The resulting product was analyzed by C-NMR, which had an average composition of 25 for m, 50 for n and 25 for q.

Embodiment 3

[0046]

[0047] Get 100g methyl hydrogen silicone oil (hydrogen 1.62%) and 50g CF 3 (CF 2 ) 5 CH=CH 2 In a 1L three-necked flask, add 100ml of isopropanol, place the three-necked flask in a water bath, add 5ml of isopropanol solution of chloroplatinic acid (concentration: 1g / 100ml) dropwise while stirring, and react at room temperature for 10h. Evaporate unreacted CF under reduced pressure 3 (CF 2 ) 5 CH=CH 2 monomer.

[0048] Infrared spectrum shows 1260cm -1 There is a peak (C-F), indicating that a fluorine-containing alkyl group has been inserted into the hydrogen-containing silicone oil segment, at 2200cm-1 There is a peak (Si-H), indicating that the product contains active hydrogen.

[0049] use 29 Si-NMR, 13 The resulting product was analyzed by C-NMR, which had an average composition of 19 for m, 62 for n and 19 for q.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com