Quantum dot and preparation method thereof

A technology of quantum dots and precursors, applied in the field of quantum dots, can solve the problems of low luminous efficiency of cadmium-free quantum dot materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] The present invention also provides a method for preparing quantum dots, comprising the steps of:

[0084] In a reaction system containing a dispersant and a solvent, the non-metallic precursor and the first metal precursor are reacted to form a quantum dot nucleus solution;

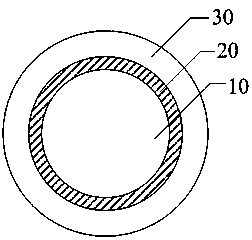

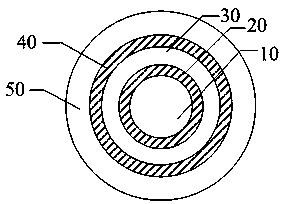

[0085] Adding a second metal precursor to the quantum dot core solution to form a metal layer on the surface of the quantum dot core;

[0086] forming a semiconductor shell on the surface of the metal layer;

[0087] Wherein, the second metal precursor is selected from one or more of a precursor of Zn element, a precursor of Hg element, a precursor of Al element, a precursor of Ga element and a precursor of In element.

[0088]The quantum dots prepared by the method of the present invention form a metal layer covering the quantum dot core on the surface of the quantum dot core, and the metal layer can use the ligand on the surface of the quantum dot core as a link to connect with the quantum dot ...

Embodiment I

[0141] The preparation of the InP quantum dot core of this embodiment comprises the following steps:

[0142] Add 0.14 mmol of indium acetate, 0.6 mmol of oleic acid and 20 g of octadecene into a 100 mL three-necked flask, and ventilate at 150 degrees for 30 minutes to remove water and oxygen in the reaction system;

[0143] After the reaction system is filled with argon, the temperature is raised to 250 degrees;

[0144] Quickly inject 0.1 mmol P(TMS) into the reaction system 3 (Tris-trimethylsilylphosphorus) and 2 mL of octadecene were reacted at 250 degrees for 20 minutes to obtain InP quantum dot cores.

Embodiment 2

[0146] The preparation of the InPZnS quantum dot nucleus of this embodiment comprises the following steps:

[0147] Add 0.18 mmol of indium chloride, 1 mL of tetrahydrofuran, 1 mmol of zinc acetate, 0.6 mL of oleic acid and 9 mL of octadecene into a 100 mL three-neck flask, and exhaust the water at 150°C for 30 minutes to remove water in the reaction system and oxygen;

[0148] After the reaction system is filled with argon, the temperature is raised to 280 degrees;

[0149] Quickly inject 0.06 mmol P(TMS) into the reaction system 3 (Tris-trimethylsilylphosphorus), 0.4 mmol sulfur, 0.5 mL trioctylphosphine (TOP) and 0.5 mL octadecene, and reacted at 280 degrees to obtain InPZnS quantum dot cores.

[0150] InPZnS quantum dot cores with different luminous wavelengths and luminous intensities can be obtained according to the reaction time. For example, the luminous wavelength of the InPZnS quantum dot core obtained when reacting for 20 seconds is 504 nm, and the luminous effici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com