Method for manufacturing fast-charging long-circulating graphite negative pole piece

A graphite negative electrode and manufacturing method technology, which is applied in electrode manufacturing, battery electrodes, nanotechnology for materials and surface science, etc. Lithium ions cannot be transferred and other problems, so as to improve the first charge and discharge efficiency, improve the morphology and uniformity, and improve the rheological properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

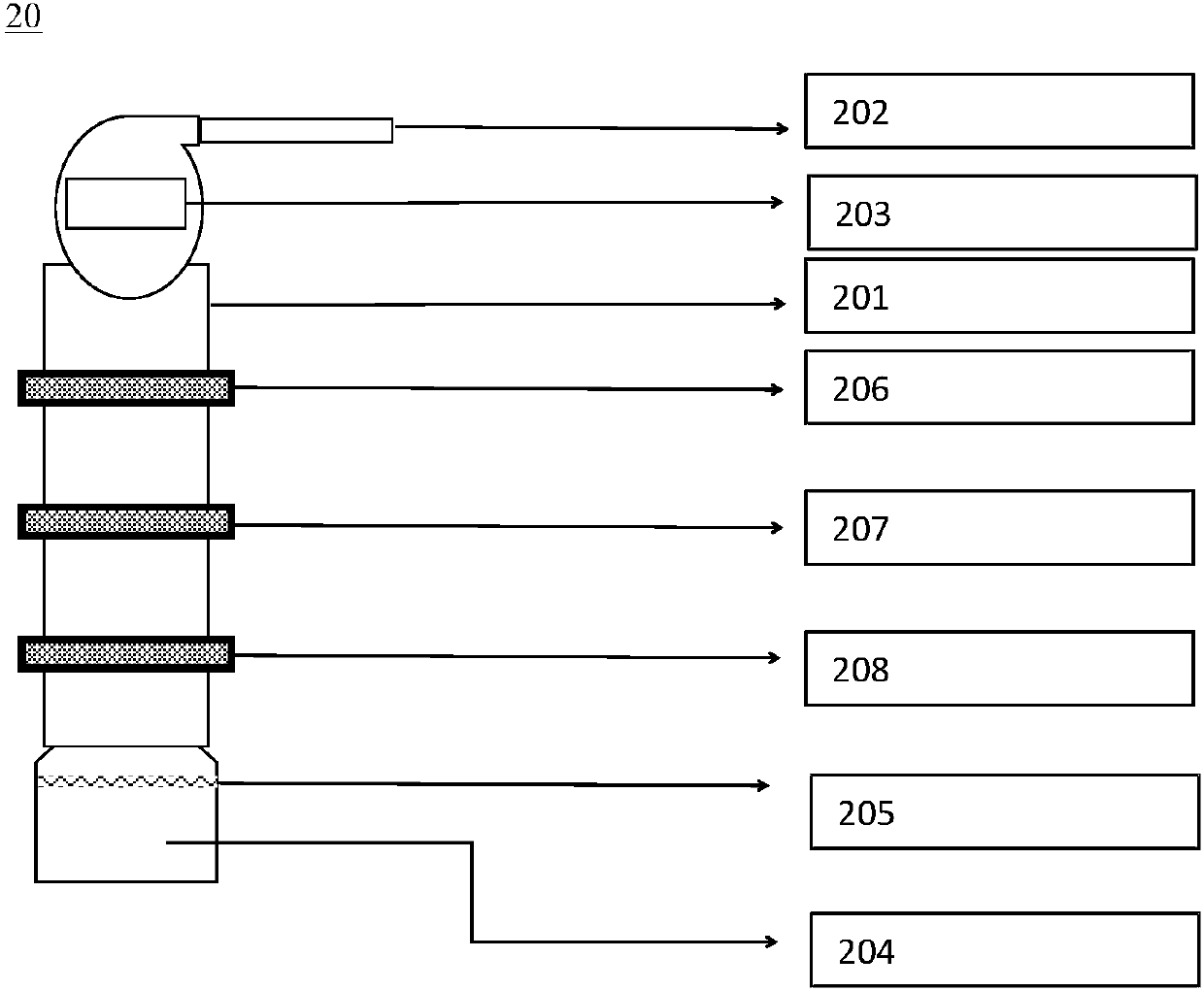

[0043] Please refer to Figure 1 to Figure 5 As shown, it shows the specific method of the preferred embodiment of the present invention, which is a method for manufacturing a fast-charging and long-cycle graphite negative electrode sheet, including the following steps.

[0044] 1) Petroleum coke is used as raw material, after primary crushing, mechanical grinding and shaping to reach the required size of petroleum coke particles.

[0045] 2) Feeding: put petroleum coke particles, high-temperature asphalt binder and stearic acid into the reactor 10, and feed while stirring.

[0046]3) Coating process: adjust the stirring speed of the reaction kettle 10 to 10-100Hz, heat in the furnace, and the heating program is: normal temperature to 200°C for 0.5-10 hours, 200°C to 400°C for 1-10 hours, 400°C to 600°C for 1- 10 hours, constant temperature at 600°C for 1-10 hours; during the heating process, the high-temperature asphalt binder undergoes the process of softening and melting, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com