Preparation method of Pt-based catalyst for fuel cell

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex preparation process, limited practical application, high energy consumption, etc., and achieves simple and easy method, convenient for large-scale production, high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

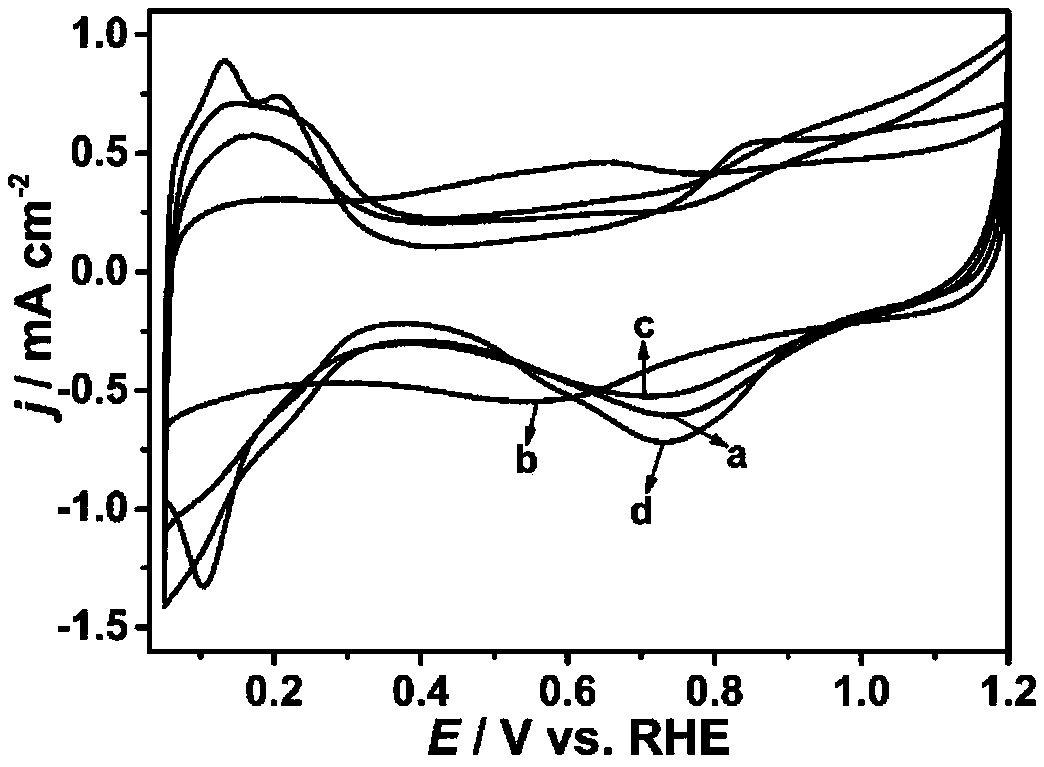

Embodiment 1

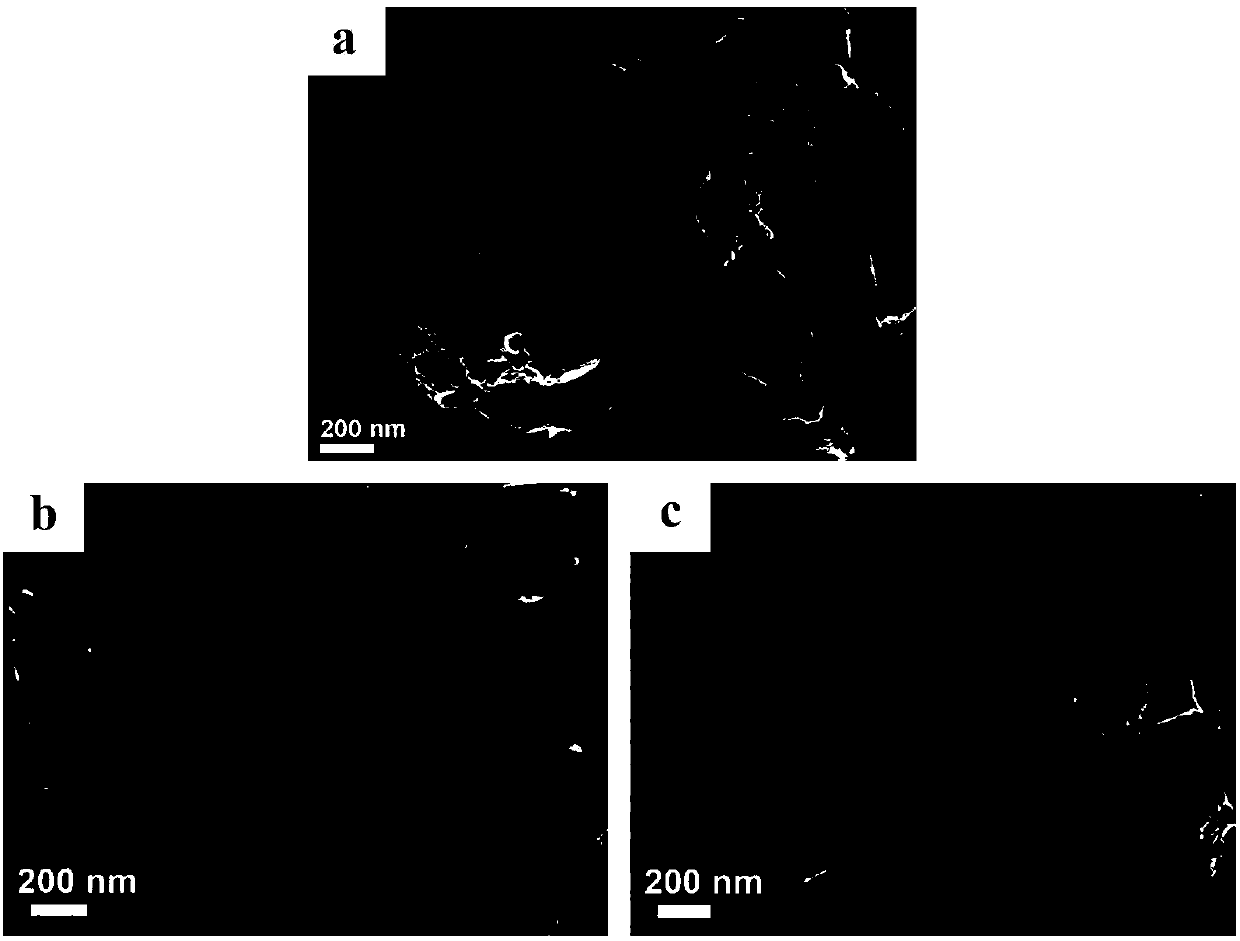

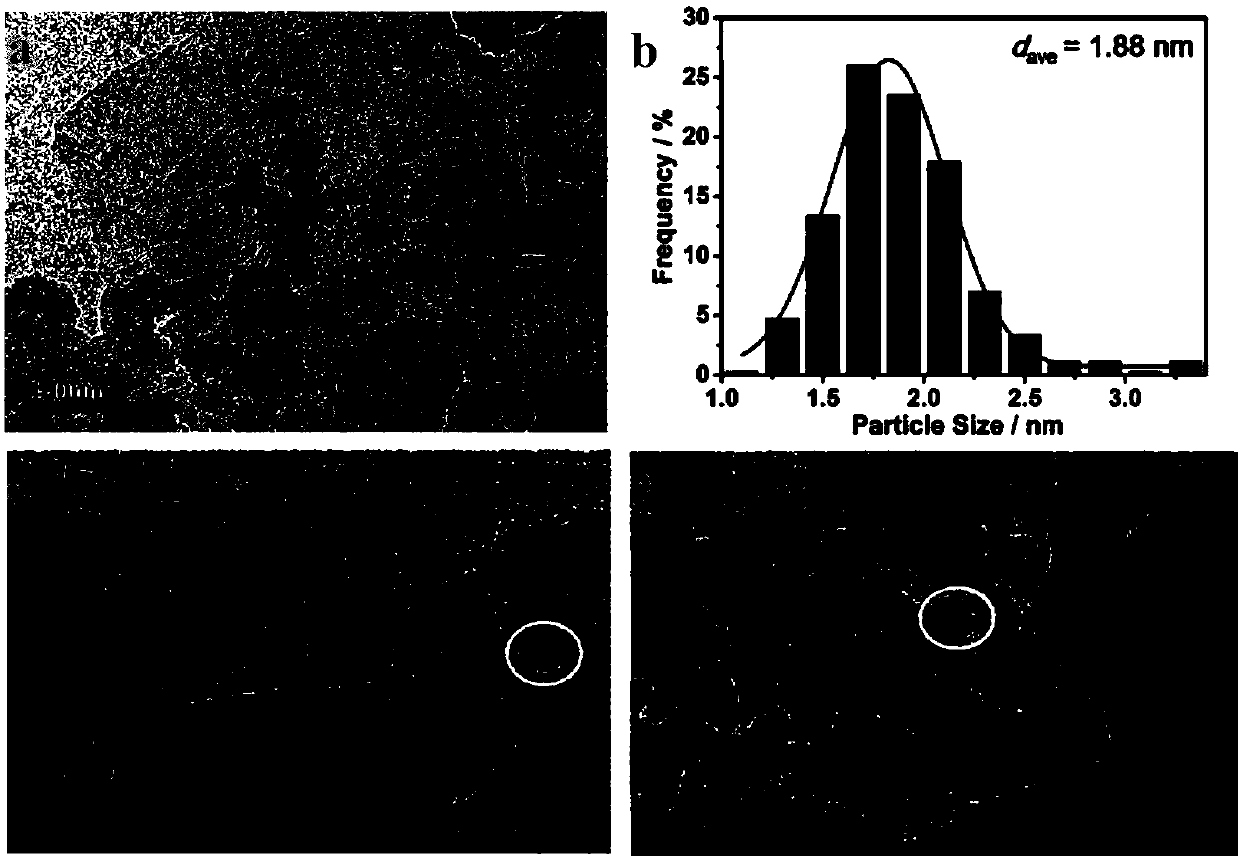

[0031] 1) Ultrasonic dispersion of carbon black in deionized water, adding cationic polymer PDDA, so that the mass ratio of carbon black to PDDA is 1:10. After ultrasonic stirring for 3 hours, wash and filter with deionized water to obtain positively charged functionalized carbon black (FCB);

[0032] 2) Redisperse the above-mentioned functionalized carbon black into deionized water, add a water dispersion of graphene oxide with a concentration of 0.5 mg / ml, so that the mass ratio of functionalized carbon black to graphene oxide is 2:1, and ultrasonically vibrate to make It was mixed evenly, and continued stirring at room temperature for 7h to obtain a functionalized carbon black-graphene oxide composite (FCB-GO);

[0033] 3) Add ascorbic acid to the mixed dispersion in step 2), so that the mass ratio of ascorbic acid to graphene oxide is 20, stir and react at 95°C for 12 hours, then centrifuge and wash to obtain a functionalized carbon black-graphene composite (FCB -rGO);

...

Embodiment 2

[0050] 1) Ultrasonic dispersion of carbon black in deionized water, adding cationic polymer PDDA, so that the mass ratio of carbon black to PDDA is 1:10. After ultrasonic stirring for 3 hours, wash and filter with deionized water to obtain positively charged functionalized carbon black (FCB);

[0051] 2) Redisperse the above-mentioned functionalized carbon black into deionized water, add a water dispersion of graphene oxide with a concentration of 0.5 mg / ml, so that the mass ratio of functionalized carbon black to graphene oxide is 4:1, and ultrasonically vibrate to make It was mixed evenly, and continued to stir at room temperature for 12h to obtain a functionalized carbon black-graphene oxide composite (FCB-GO);

[0052] 3) Add hydrazine hydrate to the mixed dispersion in step 2), so that the mass ratio of hydrazine hydrate to graphene oxide is 1:1, stir and react at 95°C for 6 hours, and then centrifugally wash to obtain functionalized carbon black-graphene Complex (FCB-rG...

Embodiment 3

[0056] 1) The carbon black was ultrasonically dispersed in deionized water, and the cationic polymer PDDA was added so that the mass ratio of carbon black to PDDA was 1:20. After ultrasonic stirring for 3 hours, wash and filter with deionized water to obtain positively charged functionalized carbon black (FCB);

[0057] 2) Redisperse the above-mentioned functionalized carbon black into deionized water, add a water dispersion of graphene oxide with a concentration of 0.5 mg / ml, so that the mass ratio of functionalized carbon black to graphene oxide is 1:2, and ultrasonically vibrate to make It was mixed evenly, and continued to stir at room temperature for 10h to obtain a functionalized carbon black-graphene oxide composite (FCB-GO);

[0058] 3) Add sodium borohydride to the mixed dispersion in step 2), so that the mass ratio of sodium borohydride to graphene oxide is 10, stir and react at 60° C. for 12 hours, then centrifuge and wash to obtain functionalized carbon black-graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com