Treatment method and treatment device for FCC regeneration flue gas

A technology for regenerating flue gas and treatment methods, applied in the direction of gaseous effluent wastewater treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high equipment costs, expensive ozone generators, etc., and achieve the effect of waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

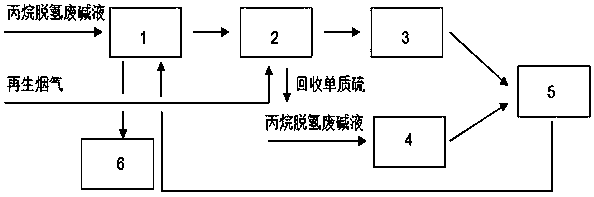

[0030] Adopt the present invention to attach figure 1 In the process shown, the FCC regeneration flue gas is treated with propylene refining waste lye. In flue gas, SO 2 Concentration is 2970mg / m³, NO concentration is 2320 mg / m³, NO 2 The concentration is 530mg / m³. The water quality of propylene refining waste lye is: 6.83wt% sodium sulfide, 4.85wt% sodium hydrosulfide, 117300mg / L COD, and 13.5 pH.

[0031] Divide propylene refining waste lye into two parts, one part is acidified with 98wt% sulfuric acid, the pH at the end of acidification is controlled to be 4.0, the gas generated by acidification is collected, and the molar ratio of hydrogen sulfide in acidification gas to sulfur dioxide in FCC regeneration flue gas is 2 :1 to react, remove sulfur dioxide in flue gas, and collect desulfurized flue gas. According to the molar ratio of NO and air in the desulfurization flue gas of 1:15, the air is passed to oxidize NO to NO 2 . Add solid sodium hydroxide to the remaining...

Embodiment 2

[0034] Adopt the present invention to attach figure 1 In the process shown, the FCC regeneration flue gas is treated with propylene refining waste lye. In flue gas, SO 2 Concentration is 2120mg / m³, NO concentration is 1370mg / m³, NO 2 The concentration is 420mg / m³. The water quality of propylene refining waste lye is: 4.8wt% sodium sulfide, 3.4wt% sodium hydrosulfide, 82400mg / L COD, and 13.8 pH.

[0035] Divide propylene refining waste lye into two parts, one part is acidified with 98wt% sulfuric acid, the pH at the end of acidification is controlled to be 4.5, the gas produced by acidification is collected, and the molar ratio of hydrogen sulfide in acidification gas to sulfur dioxide in FCC regeneration flue gas is 1.5 :1 to react, remove sulfur dioxide in flue gas, and collect desulfurized flue gas. According to the molar ratio of NO and air in the desulfurization flue gas of 1:10, the air is passed to oxidize NO to NO 2 . Add solid sodium hydroxide to the remaining wa...

Embodiment 3

[0038] Same as Example 1, the difference is that the gas-liquid reactor adopts a sleeve-type internal circulation bubbling flow reactor, the reaction pressure is controlled at 0.3MPa, and the waste caustic is fed intermittently, and enters the annulus between the inner and outer cylinders from the upper part of the reactor , the regenerated flue gas is continuously fed, and enters the inner cylinder from the bottom of the reactor. Using the lifting effect of the flue gas, the gas-liquid mixture reacts while flowing upward in the inner cylinder of the reactor, and a part of the mixed material passes through the pressure on the upper part of the reactor. The control valve discharges, the remaining material flows downward in the ring gap, and the discharged gas-liquid mixture enters the gas-liquid separator.

[0039] After the above treatment, the removal rate of sulfur dioxide in the flue gas is 99.5%, the removal rate of nitrogen oxides reaches 99.1%, and the purified gas meets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com