A method for separating and purifying pentamethylenediamine

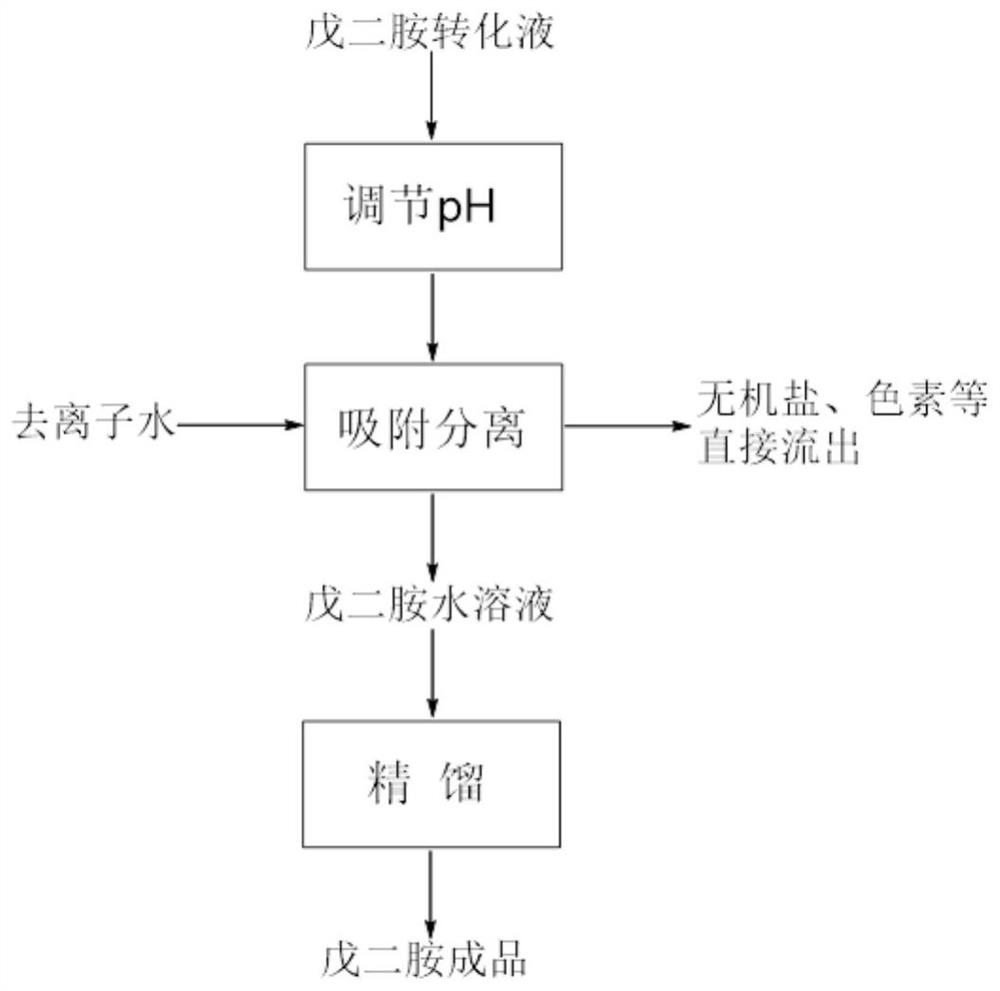

A technology for separation and purification of pentamethylenediamine, which is applied in the fields of purification/separation of amino compounds, organic chemistry, etc. It can solve problems such as salt, pigment, and impurity proteins, and achieve the effects of mild desorption conditions, high product quality, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation and pretreatment of pentamethylenediamine conversion solution

[0044] The source of the aqueous solution of the crude product of pentamethylenediamine is not particularly limited, and it can be any conversion solution containing pentamethylenediamine prepared by any biological method, for example, the pentamethylenediamine obtained after lysine or lysine salt is catalyzed by lysine decarboxylase Crude conversion solution. Add one or more of calcium oxide, calcium hydroxide, and sodium hydroxide to the conversion solution to adjust the pH of the system to 12-13.0, and then centrifuge at 6000-8000 rpm for 15-20 minutes to obtain an aqueous solution of pentamethylenediamine.

[0045] The content of pentamethylenediamine in the fermentation broth after the above pretreatment is about 110-120 g / L.

Embodiment 2

[0047] Preparation and pretreatment of modified adsorption resin

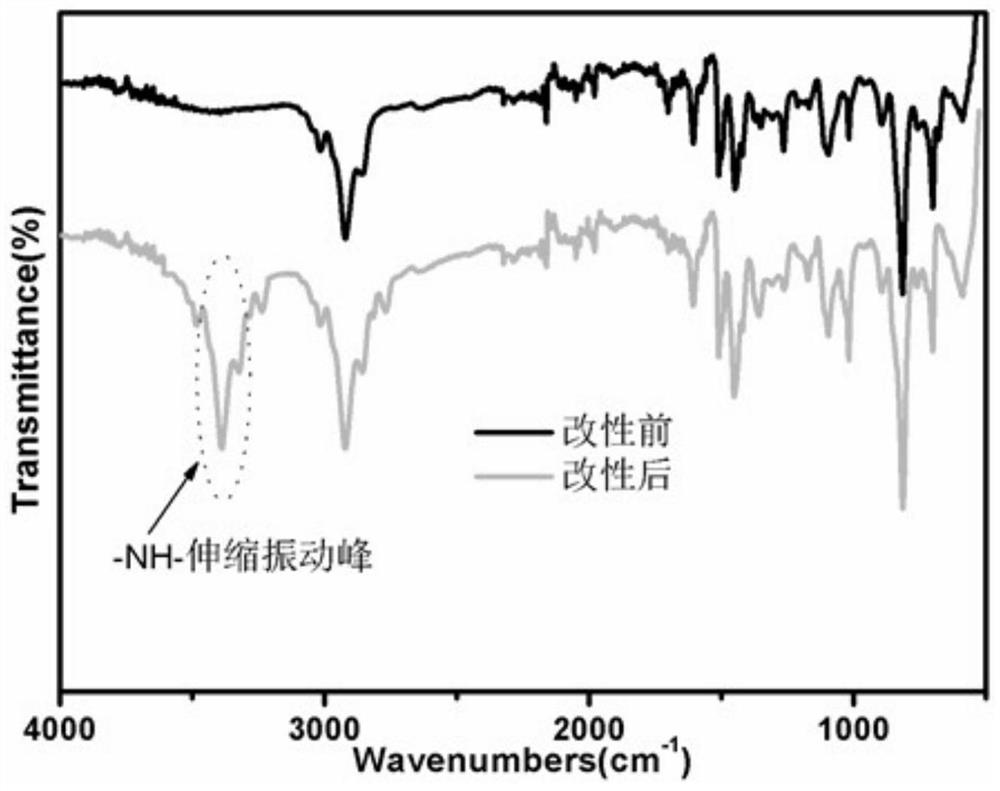

[0048] That is, a weakly polar adsorption resin with styrene as a monomer and divinylbenzene as a crosslinking agent is modified with methylamine. The modified adsorption resin has high polarity, good hydrophilicity, and an average particle size of 0.4~0.8mm, water content 41~47wt%, average pore diameter 4.6~6.3nm, porosity 30%~40%, wet density 1.12g / cm 3 , the average specific surface area is 786~862m 2 / g, average pore volume 0.97~1.12cm 3 / g, the functional group is an amine group.

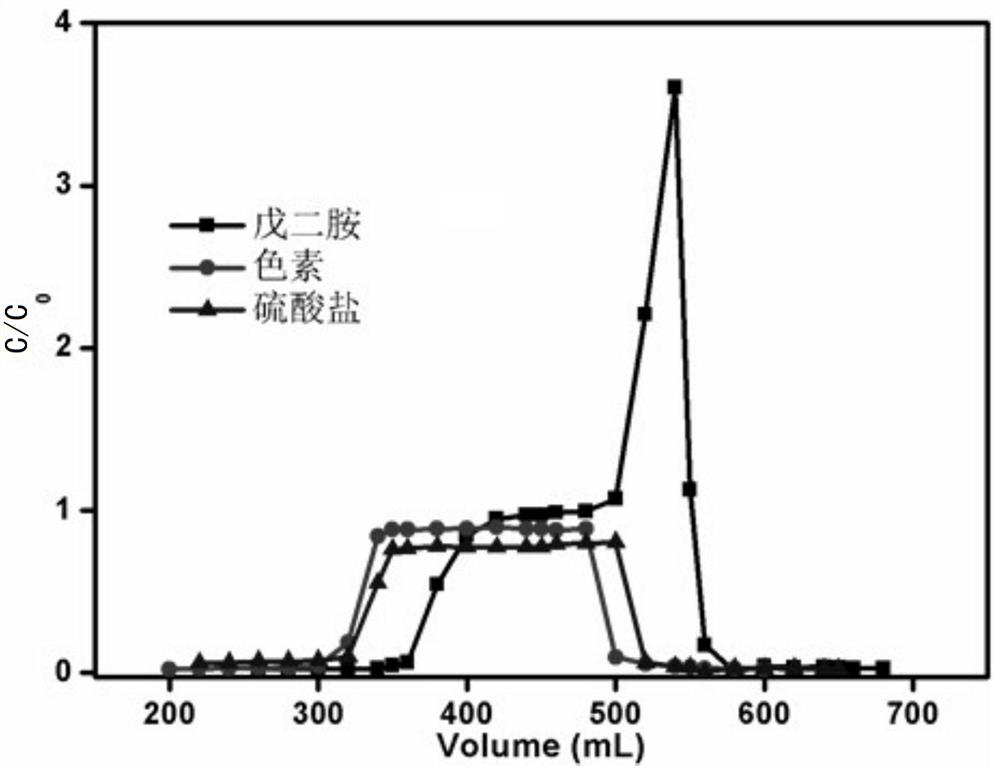

[0049] figure 2 To prepare the breakthrough curve of the resulting modified adsorption resin; image 3 To prepare the infrared spectrum of the modified adsorption resin.

[0050] Pretreatment of the modified adsorption resin: wash the resin with ethanol at a flow rate of 2BV / h, wash away the ethanol with deionized water, and set aside.

[0051] Table 1 Adsorption performance parameter table of adsorption resin

[0052] ...

Embodiment 3

[0054] Fixed bed resin column separation

[0055] The concentration of the pentamethylenediamine conversion liquid after the pretreatment of Example 1 is 118g / L, and the adsorption column equipped with the modified adsorption resin after the pretreatment of Example 2 is passed from top to bottom at a flow rate of 4BV / h, using a fixed bed Adsorption, the ratio of height to diameter of the resin column is 15, pentamethylenediamine is selectively adsorbed, and the feeding is stopped after the adsorption is saturated; the liquid in the column is drained, and the impurities are washed with deionized water at a flow rate of 2BV / h until the effluent is It does not contain impurities such as inorganic salts and residual sugar. The consumption of detergent is 1.5BV, and then the deionized water is drained; deionized water is added dropwise to the top of the adsorption column at a flow rate of 0.5BV / h for desorption. When the desorption effluent When the concentration of pentamethylened...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com