Preparation method of plant molluscacide, namely thiamine disulfide

A molluscicide and molluscicide technology, which is applied in the synthesis field of known compounds, can solve problems such as not going deep into the process, and achieve the effects of operability of the process, convenient product separation and simple reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

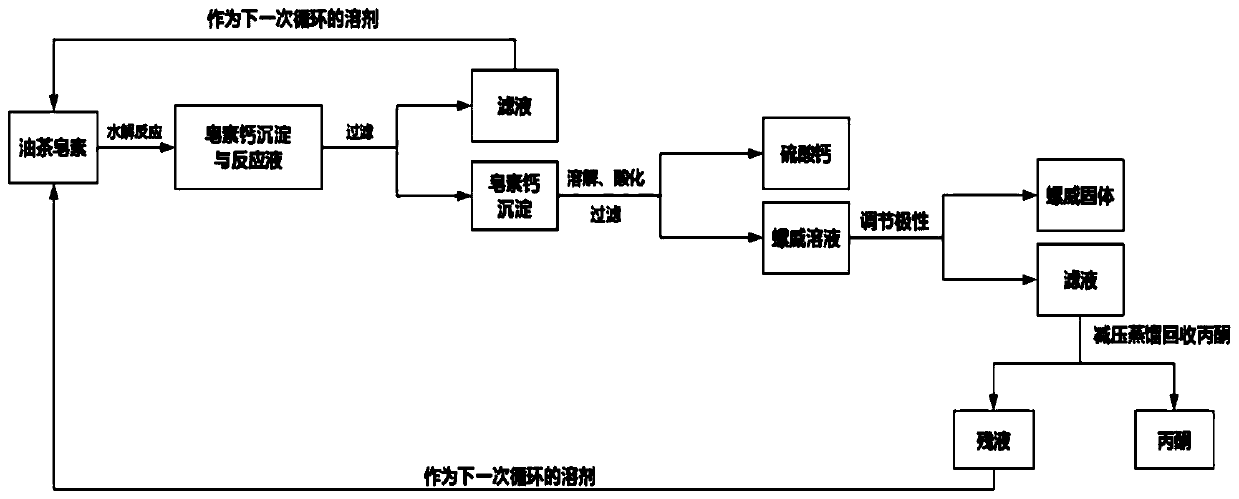

Method used

Image

Examples

Embodiment 1

[0054] 1. Hydrolysis and calcification of camellia saponin

[0055] Take by weighing 1.1g of calcium hydroxide in a three-necked flask, add 75ml of deionized water, stir evenly, then weigh 8.3g of tea saponin (mass fraction is 60%, containing 5g of tea saponin), stir and mix evenly, and It was heated to 40° C., stirred with a stirrer, and reacted stably for 12 hours to obtain khaki-colored calcium saponin, which was washed 1 to 2 times with a small amount of deionized water. After suction filtration with a vacuum pump, put the saponin calcium into a vacuum drying oven at 50-75° C. for 12 hours to obtain 6.4 g of dry saponin calcium with a yield of 77.1%.

[0056] 2. Acidified snailcarb solution of saponin calcium

[0057] The saponin calcium solid obtained in the previous step is dispersed with 100mL deionized water, and stirred with a magnetic stirrer, and at room temperature, it is 10% sulfuric acid that the mass fraction is added dropwise with a separatory funnel, and the ...

Embodiment 2

[0061] 1. Hydrolysis and calcification of camellia saponin

[0062] Take by weighing 1.1g of calcium hydroxide in a three-necked flask, add 75ml of deionized water, stir evenly with water, then weigh 8.3g of Camellia saponin (60% by mass fraction, containing 5g of Camellia saponin) and mix uniformly, then heat it Stable reaction at 50°C for 12 hours to obtain khaki-colored calcium saponin, which was washed 1-2 times with a small amount of deionized water. After filtering with a vacuum pump, put the calcium saponin into a vacuum drying oven at 50-75° C. for 12 hours to obtain 7.1 g of dry calcium saponin with a yield of 85.5%.

[0063] 2. Acidified snailcarb solution of saponin calcium

[0064] According to the operation steps in Example 1, the saponin obtained in the previous step was acidified to obtain the spirovil solution.

[0065] 3. Refined by Luowei

[0066] According to the operation steps in Example 1, the conflucarb solution was treated to obtain 3.8 g of confluca...

Embodiment 3

[0068] Take by weighing 1.1g of calcium hydroxide in a three-necked flask, add 75ml of deionized water, stir evenly, then weigh 8.3g of tea saponin (mass fraction is 60%, containing 5g of tea saponin), stir and mix evenly, and It was heated to 90°C. Use a stirrer to stir and react stably for 12 hours. Saponin calcium precipitation cannot be obtained. The reaction solution turns black and has a foul smell. The Molish experiment and Libermann Burchard experiment are carried out on the reaction solution. It is found that there is no characteristic color, which can be judged at a temperature of 90 ° C. Under reaction 12h can cause camellia saponin to go bad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com