High-flame-retardancy PC composite material suitable for FDM and preparation method

A composite material, high flame retardant technology, applied in the field of FDM molding, can solve the problem of poor flame retardant, achieve the effect of improving the flame retardant effect, reducing thermal degradation and hydrolysis, and avoiding the reduction of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

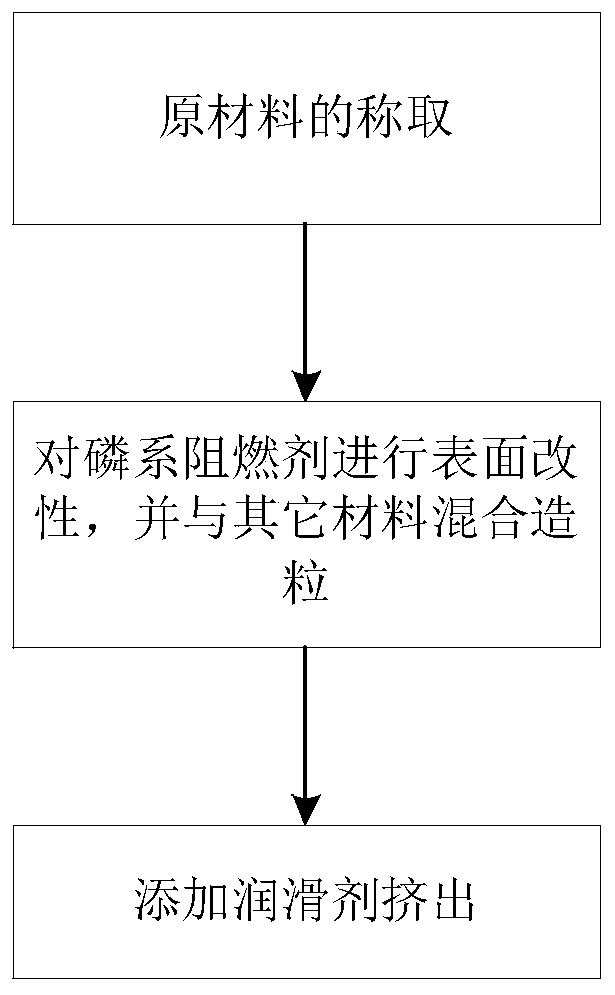

Method used

Image

Examples

Embodiment 1

[0043] (1) Take each raw material respectively by weight ratio as follows:

[0044] Polycarbonate raw material: 90 parts

[0045] Red phosphorus flame retardant: 2.09 parts

[0046] PTFE: 0.1 parts

[0047] Synergist FR-18: 0.2 parts

[0048] Silane coupling agent: 2.0 parts

[0049] Silicone oil: 1.0 parts

[0050] Chain extender MDS601: 0.8 parts

[0051] Toughener MBS: 2 parts

[0052] Ultraviolet absorber Chiguard UV-5411: 0.3 parts

[0053] (2) Wash and dry the red phosphorus flame retardant powder, then use alcohol solvent and silane coupling agent to carry out surface modification treatment on it, dry and sieve to obtain the inorganic powder after surface modification;

[0054] (3) Mix the surface-modified red phosphorus flame retardant powder, PC material and low-boiling point organic solvent, keep it warm for a period of time, and finally obtain phosphorus-based flame retardant composite PC material aggregates, which are modified and granulated by twin-screw fo...

Embodiment 2

[0057] (1) Take each raw material respectively by weight ratio as follows:

[0058] Polycarbonate raw material: 85 parts

[0059] Red phosphorus: 3.0 parts

[0060] PTFE: 0.3 parts

[0061] Synergist MMT: 0.2 parts

[0062] Titanate coupling agent: 1.0 parts

[0063] Silicone oil: 2 parts

[0064] Chain extender MDS601: 0.6 parts

[0065] Toughening agent MBS: 0.5 parts

[0066] UV absorber Hostavin B-CAP: 0.3 parts

[0067] (2) Wash and dry the red phosphorus flame retardant powder, then use alcohol solvent and titanate coupling agent to carry out surface modification treatment on it, dry and sieve to obtain surface modified inorganic powder;

[0068] (3) Mix the surface-modified red phosphorus flame retardant powder, PC material and low-boiling point organic solvent, keep it warm for a period of time, and finally obtain phosphorus-based flame retardant composite PC material aggregates, which are modified and granulated by twin-screw for later use ;

[0069] (4) Mix ...

Embodiment 3

[0071] (1) Take each raw material respectively by weight ratio as follows:

[0072] Polycarbonate raw material: 90 parts

[0073] Phosphite: 4.0 parts

[0074] PTFE: 0.3 parts

[0075] Synergist MMT: 0.3 parts

[0076] Silane coupling agent: 0.5 parts

[0077] Silicone oil: 0.2 parts

[0078] Chain extender MDS601: 0.5 parts

[0079] Toughening agent MBS: 0.6 parts

[0080] Ultraviolet absorber Chiguard UV-5411: 0.3 parts

[0081] (2) drying the phosphite flame retardant, then modifying it with an alcohol solvent and a silane coupling agent, drying and sieving to obtain a modified powder;

[0082] (3) Mix the surface-modified phosphite flame retardant powder, PC material and low-boiling point organic solvent, keep it warm for a period of time, and finally obtain the phosphorus-based flame retardant composite PC material aggregate, which is modified and granulated by twin-screw spare;

[0083] (4) Mix and extrude the granulated phosphite flame retardant composite PC ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com