Preparation method of high-mechanical-durability environment-friendly super-hydrophobic coating layer

A super-hydrophobic coating and environmental protection technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor mechanical properties, and achieve the effect of reducing pollution, low price and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

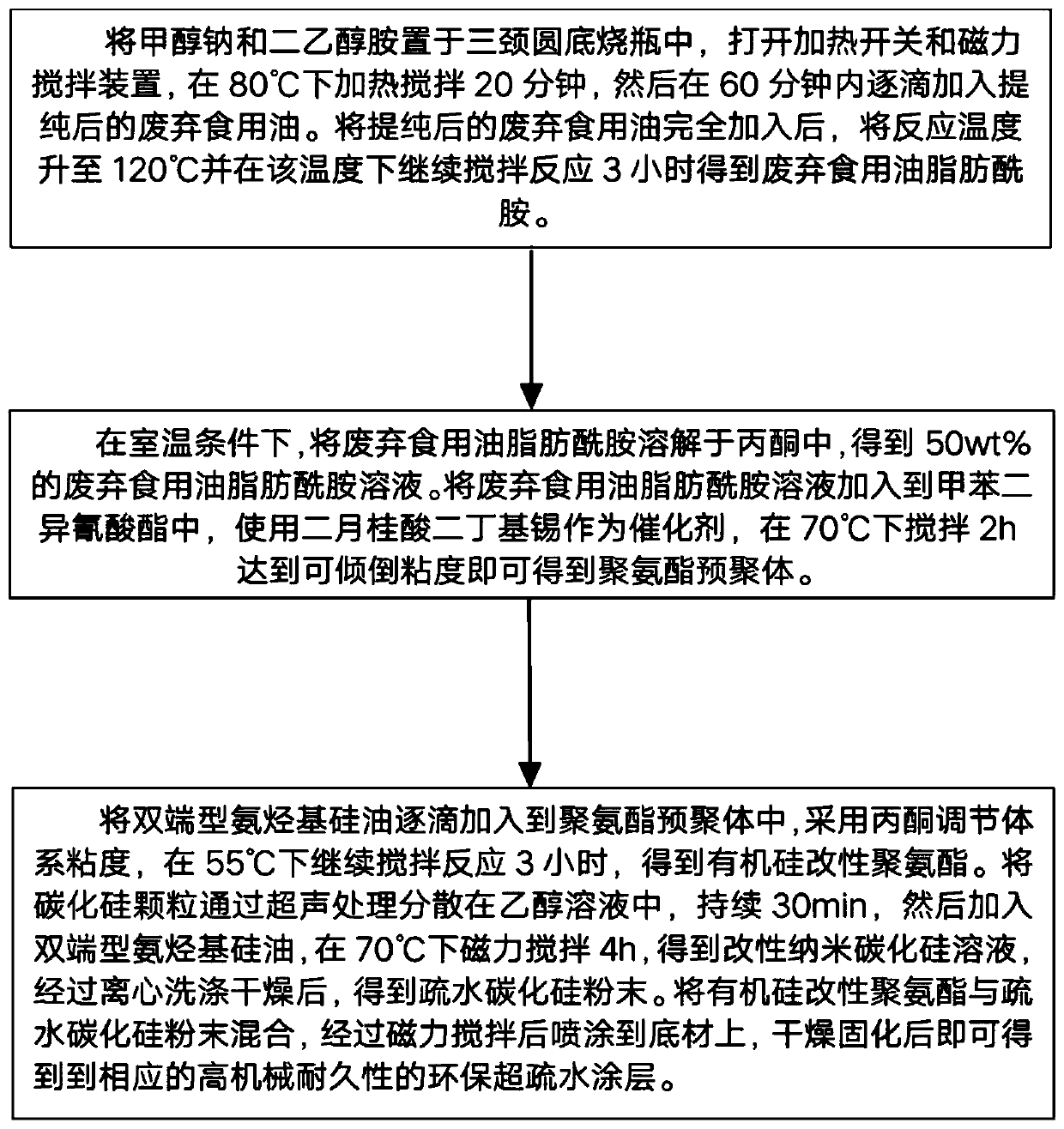

[0047]Step 1, the preparation of waste edible oil fatty acid amide, first place sodium methoxide (0.007mol) and diethanolamine (0.32mol) in a three-neck round bottom flask, turn on the heating switch and magnetic stirring device, heat and stir at 80°C for 20 minutes, then purified waste cooking oil (0.1 mol) was added dropwise over 60 minutes. After the purified waste edible oil is completely added, the reaction temperature is raised to 120° C. and the stirring reaction is continued at this temperature for 3 hours to obtain the waste edible oil fatty amide;

[0048] Step 2, the preparation of the polyurethane prepolymer, using waste edible oil fatty amide and toluene diisocyanate as raw materials, and adopting a one-step method to prepare the polyurethane prepolymer. Dissolving waste edible oil fatty amide in acetone under room temperature conditions to obtain a 50 wt% waste edible oil fatty amide solution. Add the fatty amide solution of waste cooking oil to toluene diisocya...

Embodiment 2

[0058] Step 1, the preparation of waste edible oil fatty acid amide, first place sodium methoxide (0.007mol) and diethanolamine (0.32mol) in a three-neck round bottom flask, turn on the heating switch and magnetic stirring device, heat and stir at 80°C for 20 minutes, then purified waste cooking oil (0.1 mol) was added dropwise over 60 minutes. After the purified waste edible oil is completely added, the reaction temperature is raised to 120° C. and the stirring reaction is continued at this temperature for 3 hours to obtain the waste edible oil fatty amide;

[0059] Step 2, the preparation of the polyurethane prepolymer, using waste edible oil fatty amide and toluene diisocyanate as raw materials, and adopting a one-step method to prepare the polyurethane prepolymer. Dissolving waste edible oil fatty amide in acetone under room temperature conditions to obtain a 50 wt% waste edible oil fatty amide solution. Add the fatty amide solution of waste cooking oil to toluene diisocy...

Embodiment 3

[0064] Step 1, the preparation of waste edible oil fatty acid amide, first place sodium methoxide (0.007mol) and diethanolamine (0.32mol) in a three-neck round bottom flask, turn on the heating switch and magnetic stirring device, heat and stir at 80°C for 20 minutes, then purified waste cooking oil (0.1 mol) was added dropwise over 60 minutes. After the purified waste edible oil is completely added, the reaction temperature is raised to 120° C. and the stirring reaction is continued at this temperature for 3 hours to obtain the waste edible oil fatty amide;

[0065] Step 2, the preparation of the polyurethane prepolymer, using waste edible oil fatty amide and toluene diisocyanate as raw materials, and adopting a one-step method to prepare the polyurethane prepolymer. Dissolving waste edible oil fatty amide in acetone under room temperature conditions to obtain a 50 wt% waste edible oil fatty amide solution. Add the fatty amide solution of waste cooking oil to toluene diisocy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com