Refrigerating system and process based on biomass energy

A biomass energy and refrigeration system technology, applied in refrigerators, biofuels, refrigeration components, etc., can solve the problems of poor economy, difficult to treat phenol-containing wastewater, low efficiency, etc., to improve reliability, save operating costs and equipment. The effect of high investment and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

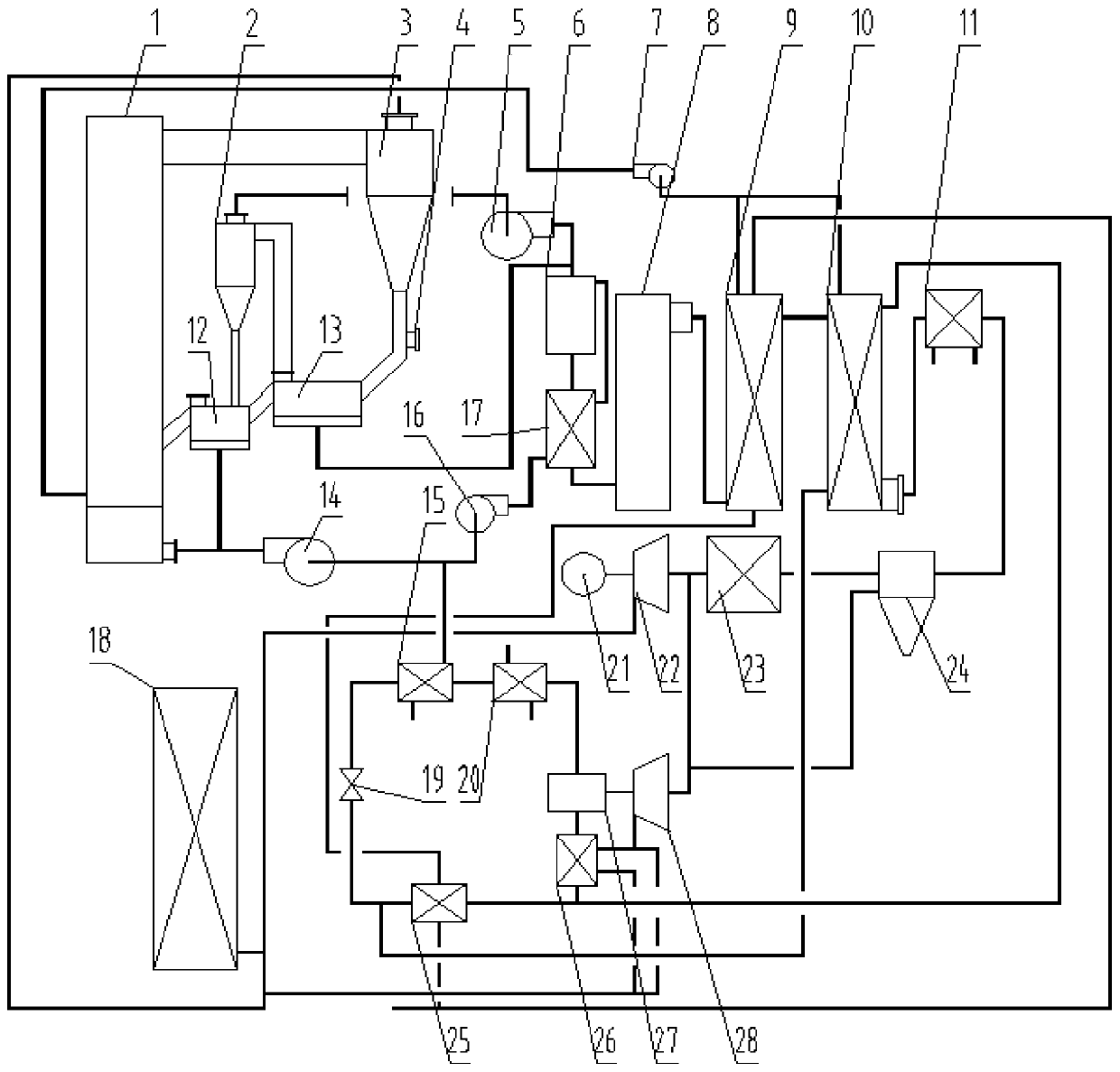

[0062] S1. Rice husk fuel is added from the fuel feeding pipe 4, and the heat carrier, biomass ash and biomass fuel are mixed and fluidized in the pyrolyzer 13. The fluidization medium is high-temperature pyrolysis gas, and the heat carrier is 1mm river sand and oxidation A mixture of calcium powder, the temperature at the inlet end of the pyrolyzer 13 is 780°C, and the temperature at the outlet end of the pyrolyzer 13 is 600°C, and the biomass fuel is pyrolyzed into high-temperature pyrolysis gas and carbon powder, and the carbon powder, heat carrier, and biomass ash are mixed Entering the feeder 12, the high-temperature pyrolysis gas enters the pyrolysis gas separator 2 from the gas outlet on the upper part of the pyrolyzer 13 for gas-solid separation, and the separated carbon powder enters the feeder 12, and undergoes high-temperature pyrolysis after separation. The gas is pressurized and conveyed by the pyrolysis gas booster fan 5;

[0063] S2. The carbon powder, heat carr...

Embodiment 2

[0073] S1. Straw fuel is added from the fuel feeding pipe 4. The heat carrier, biomass ash and biomass fuel are mixed and fluidized in the pyrolyzer 13. The fluidization medium is high-temperature pyrolysis gas, and the heat carrier is 2mm ceramic balls and calcium oxide. The mixture of powders, the temperature at the inlet end of the pyrolyzer 13 is 730°C, and the temperature at the outlet end of the pyrolyzer 13 is 550°C. The biomass fuel is pyrolyzed into high-temperature pyrolysis gas and carbon powder, and the carbon powder, heat carrier, and biomass ash are mixed into the In the feeder 12, the high-temperature pyrolysis gas enters the pyrolysis gas separator 2 from the gas outlet on the upper part of the pyrolyzer 13 for gas-solid separation, and the separated carbon powder enters the feeder 12, and the separated high-temperature pyrolysis gas Through the pyrolysis gas booster fan 5 pressurized delivery;

[0074] S2. The carbon powder, heat carrier, and biomass ash enter...

Embodiment 3

[0084] S1. Sawdust fuel is added from the fuel feeding pipe 4. The heat carrier, biomass ash and biomass fuel are mixed and fluidized in the pyrolyzer 13. The fluidization medium is high-temperature pyrolysis gas, and the heat carrier is river sand and calcium oxide of 2 mm. The mixture of powders, the temperature at the inlet end of the pyrolyzer 13 is 800°C, and the temperature at the outlet end of the pyrolyzer 13 is 690°C. The biomass fuel is pyrolyzed into high-temperature pyrolysis gas and carbon powder, and the carbon powder, heat carrier, and biomass ash are mixed into the In the feeder 12, the high-temperature pyrolysis gas enters the pyrolysis gas separator 2 from the gas outlet on the upper part of the pyrolyzer 13 for gas-solid separation, and the separated carbon powder enters the feeder 12, and the separated high-temperature pyrolysis gas Through the pyrolysis gas booster fan 5 pressurized delivery;

[0085] S2. The carbon powder, heat carrier, and biomass ash en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com