A kind of solvated composite solid electrolyte and its preparation method and application

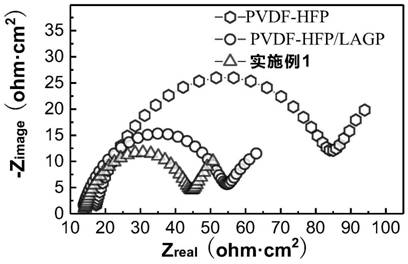

A solid electrolyte and solvation technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as inability to meet performance at the same time, achieve the effect of preventing excessive hardness and improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation process of the solvated composite solid electrolyte is as follows:

[0039] Step 1, using vinylidene fluoride-co-hexafluoropropylene and polyethylene oxide as the solute and dimethylformamide as the solvent to prepare vinylidene fluoride-co-hexafluoropropylene with a mass fraction of 5%-15% solution, and a polyethylene oxide solution with a mass fraction of 1%-5%; the two solutions are separately placed in an oven, baked at 50-70° C. for 6 hours, and then taken out to form a solution with uniform composition.

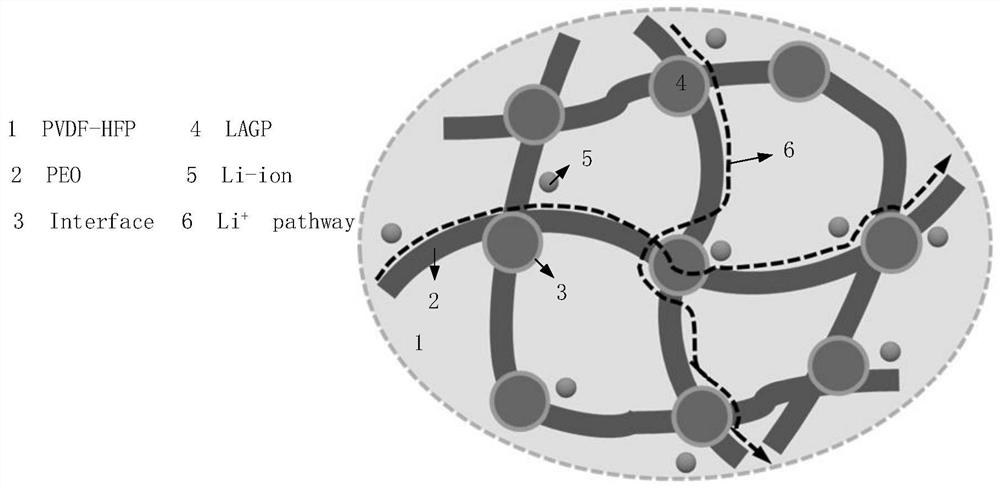

[0040] Step 2, the polyoxyethylene solution that step 1 obtains and Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 (abbreviated as LAGP) mixed and stirred at 50-70 ° C, the mixed polyethylene oxide solution Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 Among them, the mass ratio of the solid content of the two is 1: (0.6-1.5); the stirring method is preferably magnetic stirring, and the stirring speed is 300r / min, and the mixed solution is obtained by stirring evenly; ...

Embodiment 1

[0052] (1) Using vinylidene fluoride-co-hexafluoropropylene and polyethylene oxide as the solute and dimethylformamide as the solvent, respectively prepare solutions with a mass fraction of 12% and 2.5%, and place them in an oven at 60°C , After baking for 6 hours, take it out to form a uniform solution, which is conducive to dissolution.

[0053] (2) Mix and stir the polyoxyethylene solution and the LAGP solution at 60°C, the mass ratio of the solid content is 1:1.5 to prepare a mixed solution; add vinylidene fluoride-co-hexafluoropropylene solution to the mixed solution , the solid content of the added vinylidene fluoride-co-hexafluoropropylene solution is 9 times the solid content of the polyethylene oxide solution, and after continuing to stir evenly, a uniform white emulsion is obtained, which is a mixture of three substances.

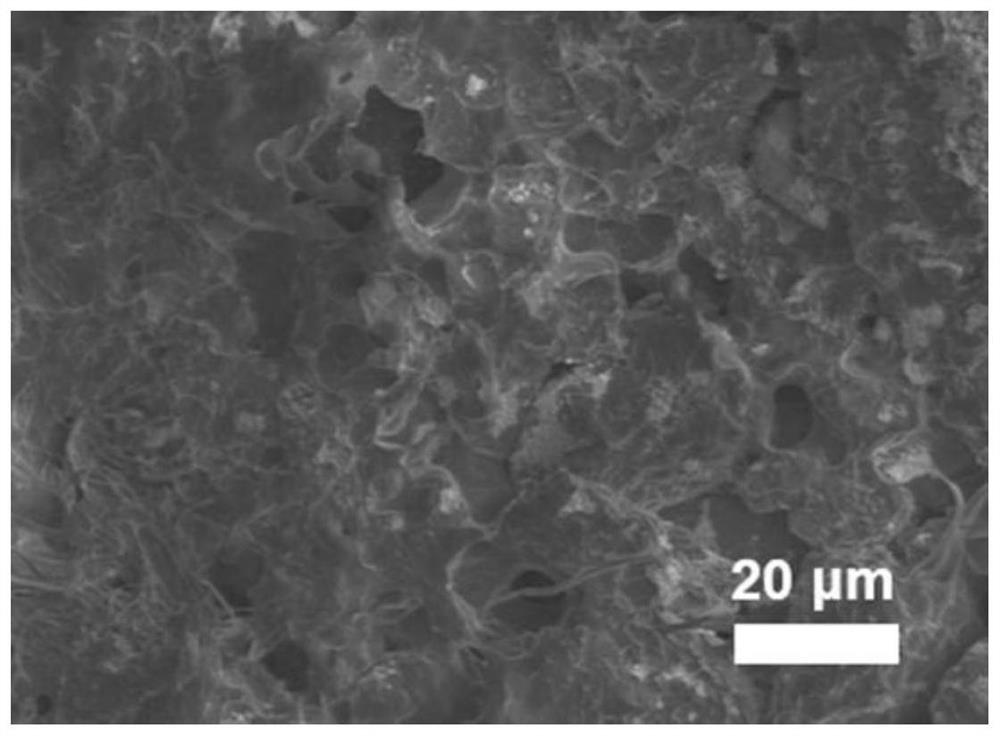

[0054] (3) Pour the white emulsion into a polytetrafluoroethylene mold, dry it at 25°C for 24 hours, and then dry it with air at 60°C for 4 hours...

Embodiment 2

[0064] (1) Prepare a 10% vinylidene fluoride-co-hexafluoropropylene solution and a 3% polyethylene oxide solution respectively, place them in an oven at 50° C., and take them out after baking for 6 hours to form a uniform solution.

[0065] (2) Mix and stir the polyoxyethylene solution and the LAGP solution at 60°C, the mass ratio of the solid content is 1:1.2 to prepare a mixed solution; add vinylidene fluoride-co-hexafluoropropylene solution to the mixed solution , the solid content of the added vinylidene fluoride-co-hexafluoropropylene solution is 9 times the solid content of the polyethylene oxide solution, and after continuing to stir evenly, a uniform white emulsion is obtained, which is a mixture of three substances.

[0066] (3) Pour the white emulsion into a polytetrafluoroethylene mold, dry it at 40°C for 12 hours, and then dry it with air at 60°C for 20 hours to obtain a composite solid electrolyte film;

[0067] (4) Preparation of solvated ionic liquid electrolyte, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com