Preparation method for sucralose

A technology of sucralose and sucrose, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the disadvantages of unfavorable automatic production and production cost control, sucralose-6-ethyl ester is easy to be thermally decomposed, Solve problems such as cumbersome process steps, achieve the effect of improving the level of clean production, improving the level of automated production, and shortening the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of sucralose provided in this example, further, the method of directly preparing sucralose from the extraction and separation intermediate (sucralose-6-ethyl ester aqueous solution), specifically includes the following steps:

[0031] (1) Take the reaction solution obtained by chlorination of sucrose-6-ethyl ester, add sodium hydroxide solution to adjust to pH = 9.0, then add concentrated hydrochloric acid to adjust to pH = 7.0, to obtain a neutralization solution;

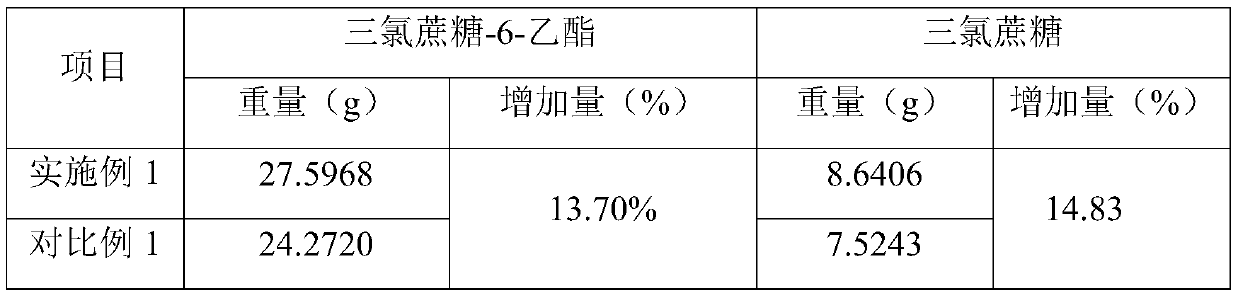

[0032] (2) Filter the neutralization solution to remove salt, measure 500mL, 666.2g of the feed solution, add 250mL of clear water, extract 3 times, and combine the extraction phases; distill and remove DMF to obtain an extract containing sucralose-6-ethyl ester 335.32g, detected by high performance liquid chromatography, contains 8.23wt% of sucralose-6-ethyl ester, and 27.5968g of sucralose-6-ethyl ester can be obtained by calculation;

Embodiment 2

[0042] The preparation method of sucralose provided in this example, further, the method of directly preparing sucralose from the extraction and separation intermediate (sucralose-6-ester aqueous solution), specifically includes the following steps:

[0043] (1) adding sodium hydroxide solution to the reaction solution obtained by chlorination of sucrose-6-ethyl ester to adjust the pH to 9.0, and then adding concentrated hydrochloric acid to adjust the pH to 7.0 to obtain a neutralizing solution;

[0044] (2) Filter the neutralization liquid to remove salt, measure 500 mL of the feed liquid, 666.4 g as the first batch, add 250 mL of water in turn, and extract 3 times. The third extraction phase of the first batch was used for the first extraction of 500mL and 666.7g of the second batch of feed liquid, and then 250mL and 250mL of clear water were added in order to extract the second batch of feed liquid;

[0045]DMF was removed by distillation to obtain 320.25 g of the first ba...

Embodiment 3

[0049] The preparation method of sucralose provided in this example, further, the method of directly preparing sucralose from the extraction and separation intermediate (sucralose-6-ester aqueous solution), specifically includes the following steps:

[0050] (1) adding sodium hydroxide solution to the reaction solution obtained by chlorination of sucrose-6-ethyl ester to adjust the pH to 9.0, and then adding concentrated hydrochloric acid to adjust the pH to 7.0 to obtain a neutralizing solution;

[0051] (2) Filter the neutralization solution to desalt, measure 500mL, 666.2g of the feed solution, add 350mL, 150mL, 350mL of water in turn, extract 3 times, combine the extraction phases; distill to remove DMF, and obtain the sucralose-6- Ethyl ester extract 340.10g. After detection by high-performance liquid chromatography, it contains 7.54wt% of sucralose-6-ethyl ester, and 25.6485g of sucralose-6-ethyl ester can be obtained by calculation;

[0052] The raffinate phase recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com