Ammonolysis method and ammonolysis composition

A composition and a technology for ammonolysis, applied in the field of ammonolysis, can solve the problems of long time-consuming, high equipment requirements, long time-consuming, etc. to drain the mixed solution of water and methanol. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

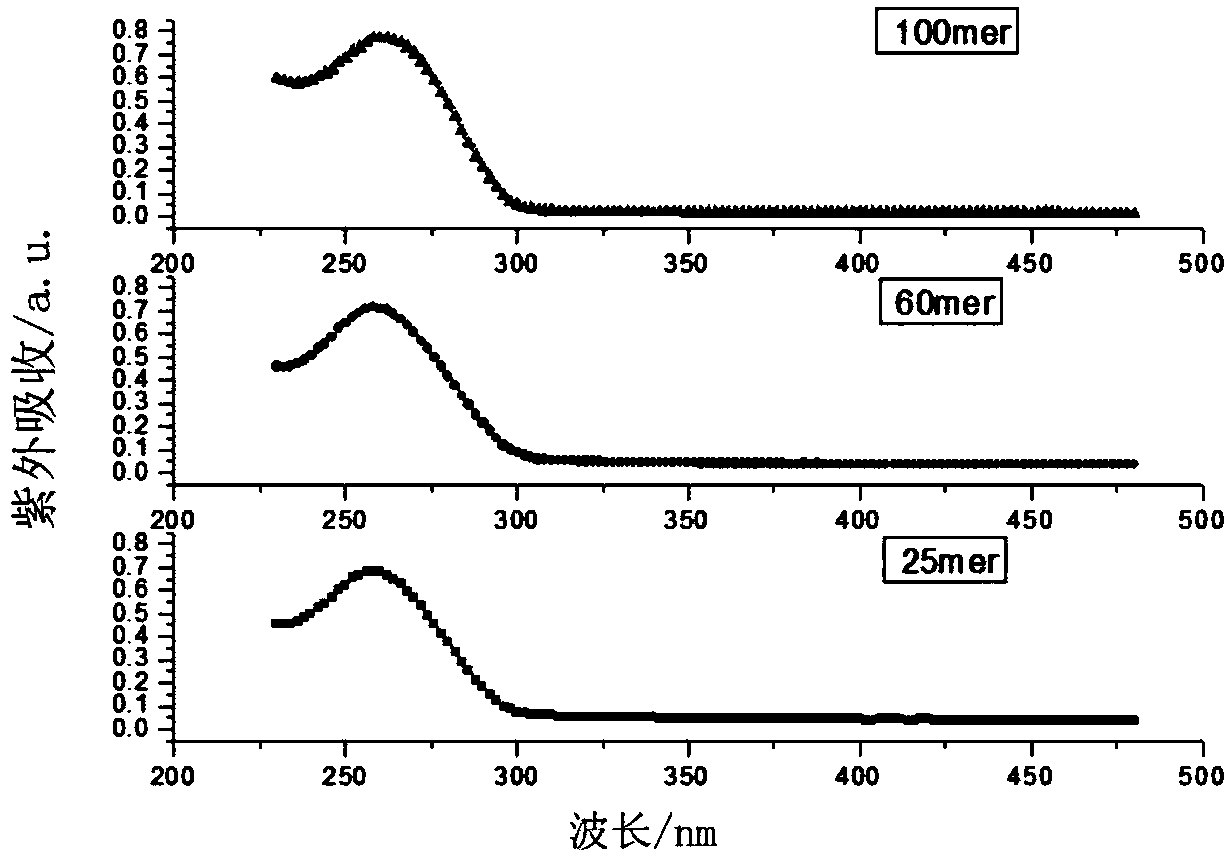

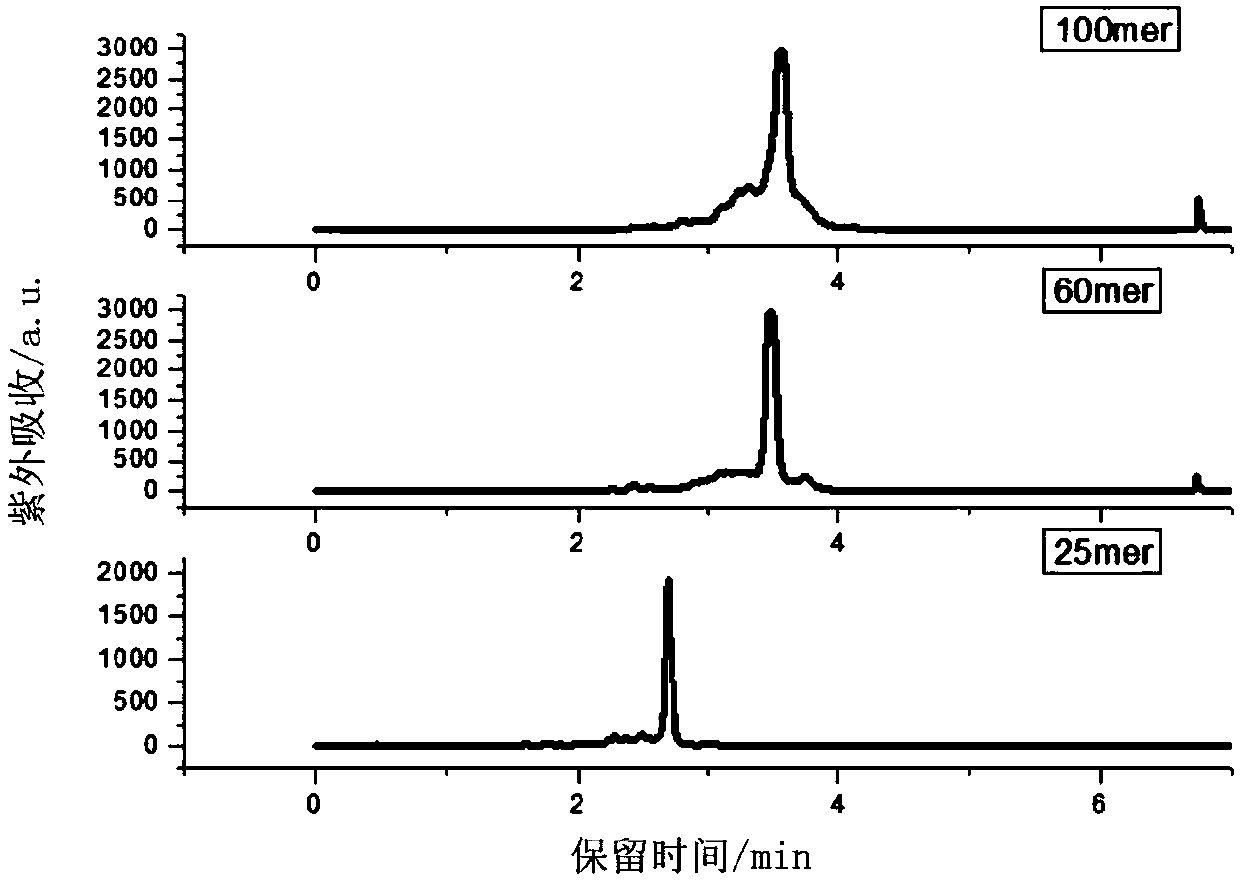

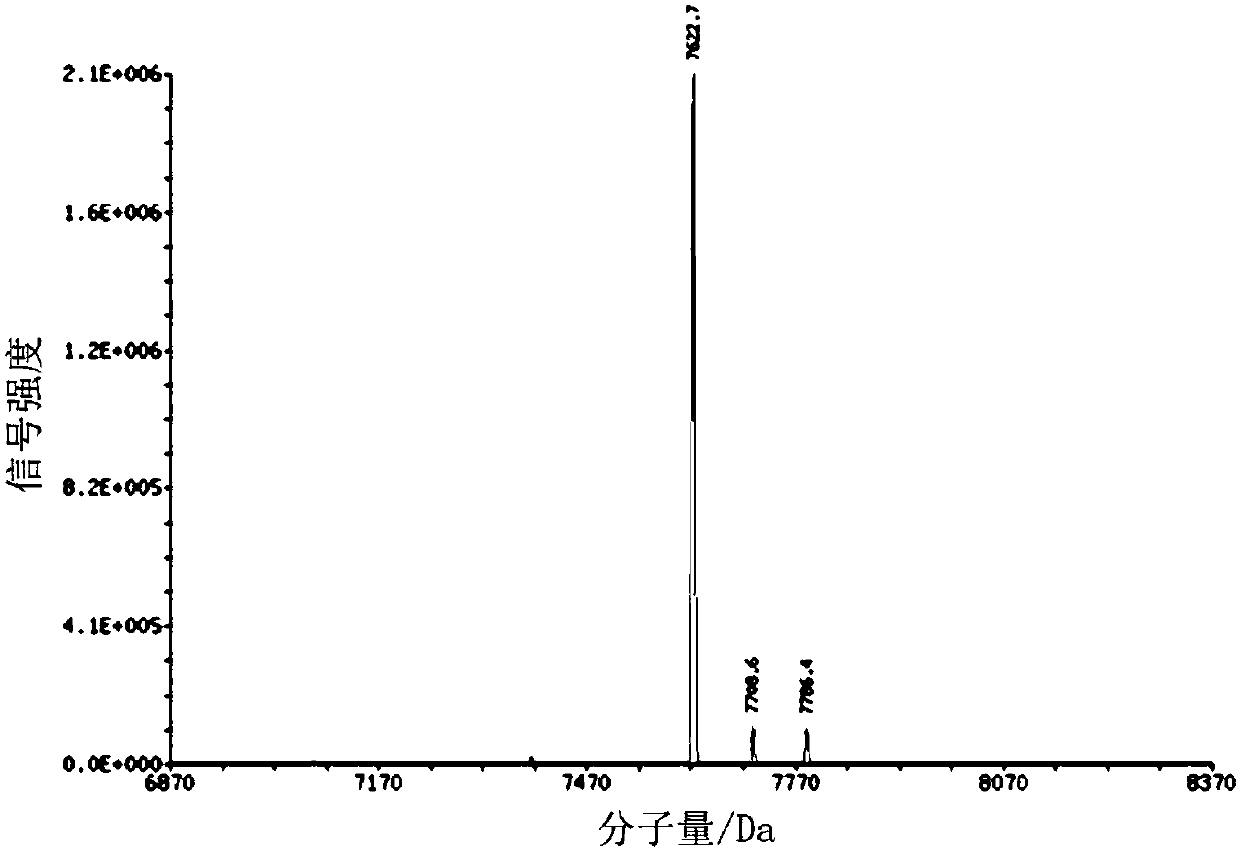

[0066] The purpose of this embodiment is to synthesize primers with a length of 25, 60 and 100 bases, and the sequences are respectively:

[0067] 5'-AAACCCAGGGCCTCAAGGACAAACC-3' (target molecular weight is 7623.0)

[0068] 5'-

[0069] TTCTTTCTCCCTAAACACTGACCTCCCGCAGTCTTCACTAGCAGGTGAGGTCACCTGTA-3' (target molecular weight 18232.8)

[0070] 5'-

[0071] GTACCGAGCTCGGATCCGCCACCATGGCTGAAAATAGTGTATTAACATCCACTACTGGGAGGACTAGCTTGGCAGACTTCTTCCATTTTTGATTCTAAAGT-3' (target molecular weight 30782.0)

[0072] 1. Primer Synthesis

[0073] Use a 50nmol synthesis column (purchased from Beijing Dinaxinke Biotechnology Co., Ltd., C1001-50), tetrazole is an activation reagent, 3% (v / v) trichloroacetic acid / dichloromethane is a deprotection reagent, and 20% (v / v) acetic anhydride / acetonitrile, 16% (v / v) nitrogen methylimidazole / acetonitrile were used as capping reagents, and 0.025M iodine solution was used as oxidizing reagents. The corresponding primer sequences were synthesized on Dr.Oli...

Embodiment 2

[0086] The purpose of this example is to synthesize primers with a length of 25, 60 and 100 bases, using traditional microwave aminolysis, and comparing the results with the microwave aminolysis composition provided by the present invention. The synthesized sequences are:

[0087] 5'-AAACCCAGGGCCTCAAGGACAAACC-3' (target molecular weight is 7623.0)

[0088] 5'-

[0089] TTCTTTCTCCCTAAACACTGACCTCCCGCAGTCTTCACTAGCAGGTGAGGTCACCTGTA-3' (target molecular weight 18232.8)

[0090] 5'-

[0091] GTACCGAGCTCGGATCCGCCACCATGGCTGAAAATAGTGTATTAACATCCACTACTGGGAGGACTAGCTTGGCAGACTTCTTCCATTTTTGATTCTAAAGT-3' (target molecular weight 30782.0)

[0092] 1. Primer Synthesis

[0093] Using a 50nmol synthesis column, tetrazole is an activation reagent, 3% (v / v) trichloroacetic acid / dichloromethane is a deprotection reagent, 20% (v / v) acetic anhydride / acetonitrile, 16% (v / v ) Nitromethylimidazole / acetonitrile is the capping reagent, and 0.025M iodine solution is the oxidizing reagent. The correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com