Trapezoidal organosilicone polymer as well as preparation method and application thereof and LED package adhesive

A technology of LED encapsulation and silicone, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of difficulty in controlling the degree of polymerization, difficulty in complete sealing, and limited heat resistance, etc., and achieve good application Foreground, good cold and heat impact, the effect of appropriate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

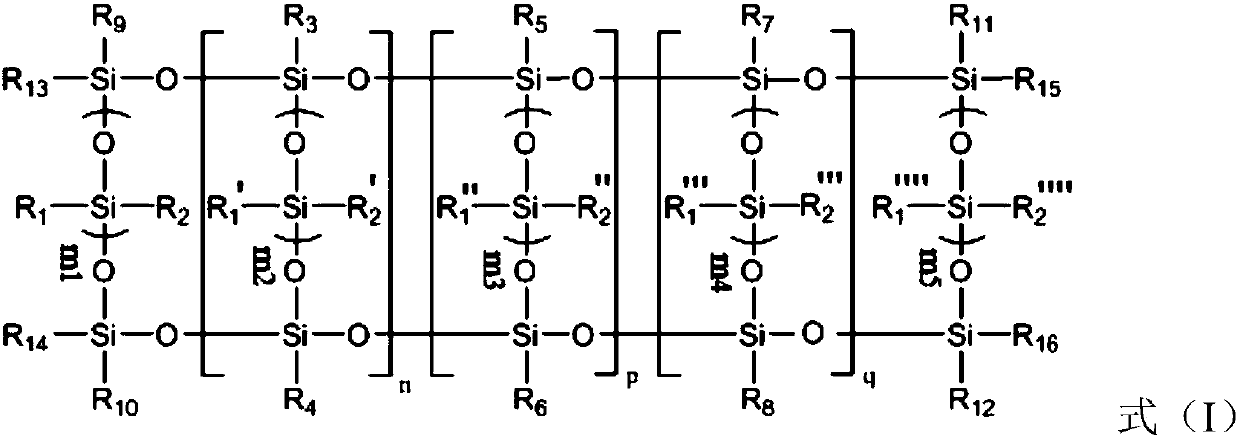

Method used

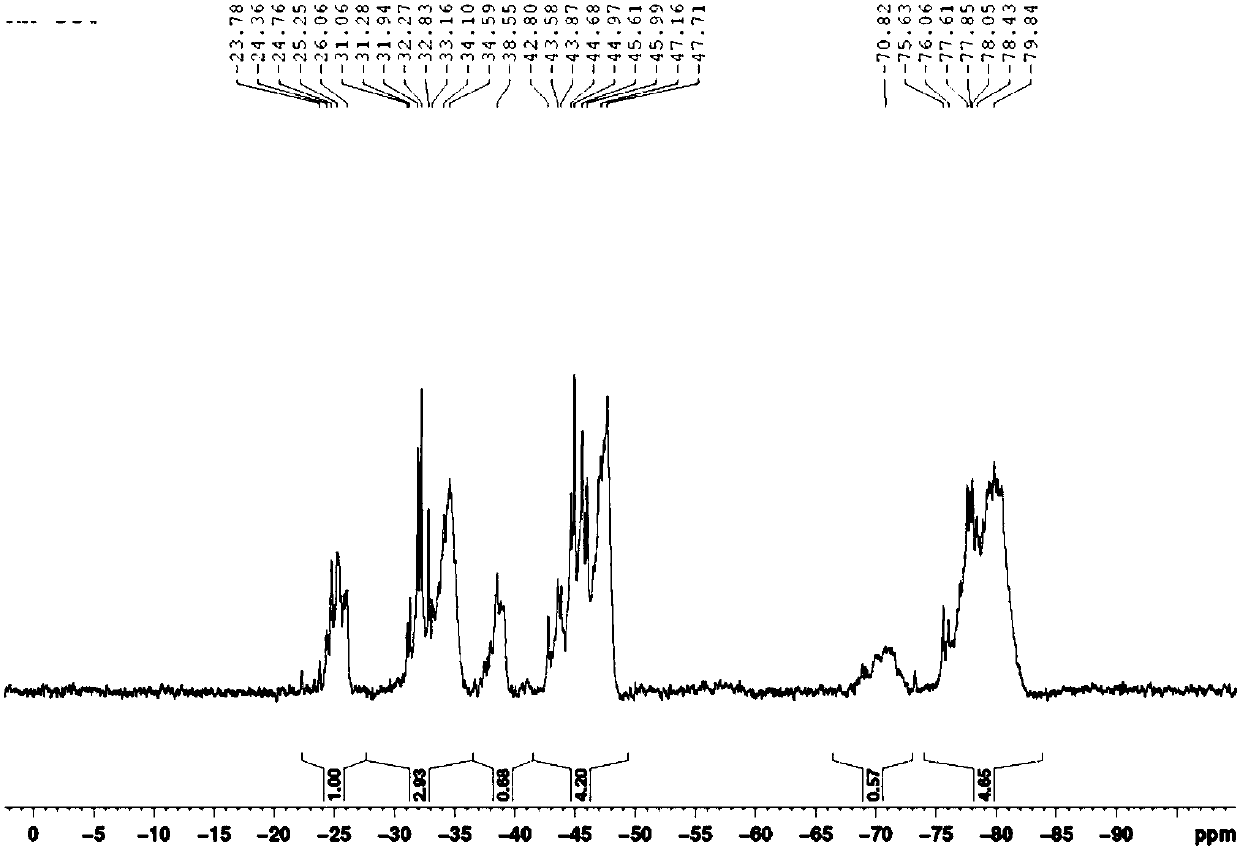

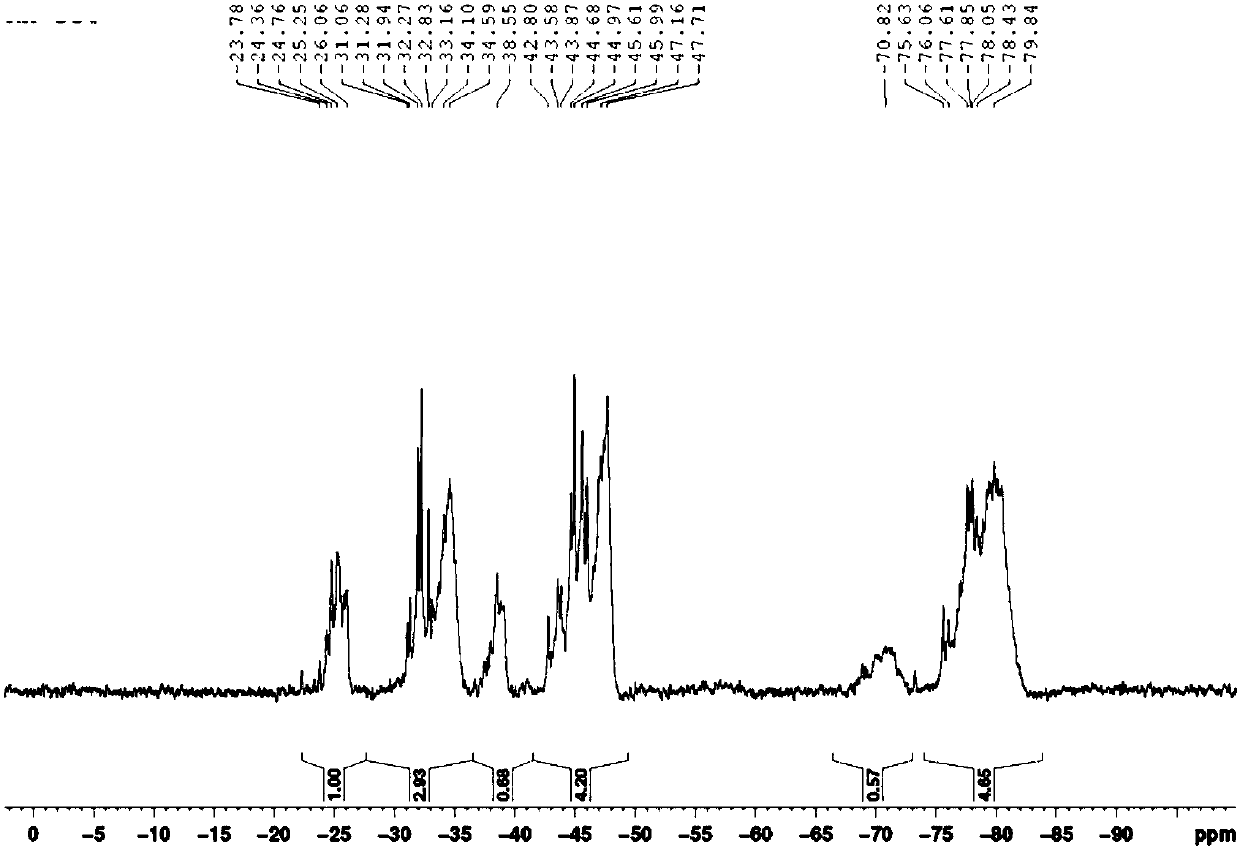

Image

Examples

preparation example 1

[0071] This preparation example is used to illustrate the ladder-shaped organosilicon polymer provided by the present invention.

[0072] (1) Under the protection of dry nitrogen, add 59.5g phenyltrimethoxysilane (0.3mol) and 32.4g diphenylsilica into a three-necked flask equipped with mechanical stirring, constant pressure dropping funnel and reflux condenser. Alcohol (0.15 mol) and 90 g of DMA, stir well and place at -15°C, add 0.1 g of DBU, and react for 8 hours to obtain intermediate 1 (monomer).

[0073] (2) At the same time, add 17.2g methylvinyldimethoxysilane (0.12mol) and 13g diphenyl into another three-necked flask equipped with dry nitrogen protection, mechanical stirring, constant pressure dropping funnel and reflux condenser. Silicone diol (0.06 mol) and 15 g of DMA were stirred uniformly and placed at 0° C., 0.6 g of DBN was added, and the intermediate 2 (blocking agent) was obtained after 24 hours of reaction.

[0074] (3) Mix the obtained Intermediate 2 with Intermed...

preparation example 2

[0080] This preparation example is used to illustrate the ladder-shaped organosilicon polymer provided by the present invention.

[0081] (1) Under the protection of dry nitrogen, add 59.5g phenyltrimethoxysilane (0.3mol) and 32.4g diphenylsilica into a three-necked flask equipped with mechanical stirring, constant pressure dropping funnel and reflux condenser. Alcohol (0.15 mol) and 90 g of DMF are stirred uniformly and placed at -15° C., 0.1 g of DBN is added, and the intermediate 1 (monomer) is obtained after 8 hours of reaction.

[0082] (2) At the same time, add 40.3g methyldiethoxysilane (0.3mol) and 32.4g diphenyl into another three-necked flask equipped with dry nitrogen protection, mechanical stirring, constant pressure dropping funnel and reflux condenser. Silicon diol (0.15 mol) and 30 g of DMA were stirred evenly and placed at -20° C., 1.5 g of dibutylamine was added, and the intermediate 2 (blocking agent) was obtained after 8 hours of reaction.

[0083] (3) Mix the obt...

preparation example 3

[0086] This preparation example is used to illustrate the ladder-shaped organosilicon polymer provided by the present invention.

[0087] (1) Under the protection of dry nitrogen, add 59.5g phenyltrimethoxysilane (0.3mol) and 32.4g diphenylsilica into a three-necked flask equipped with mechanical stirring, constant pressure dropping funnel and reflux condenser. Alcohol (0.15 mol) and 90 g of ethylene glycol methyl ether are stirred uniformly and placed at -15° C., 0.1 g of triethylenetetramine is added, and the intermediate 1 (monomer) is obtained after reaction for 10 hours.

[0088] (2) At the same time, add 13.9g of 3-methacryloxypropylmethyldimethoxy into another three-necked flask equipped with dry nitrogen protection, mechanical stirring, constant pressure dropping funnel and reflux condenser. Silane (0.06mol), 6.5g diphenylsiliconediol (0.03mol) and 10g tetrahydrofuran, stir well and place at 30℃, add 0.2g potassium tert-butoxide, react for 10h to obtain intermediate 2 (bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com