Preparation method for neutral esterase, and stickies control enzyme reagent used for waste paper papermaking process

A technology of esterase enzyme and esterase, which is applied in the field of glue control enzyme reagent and neutral esterase preparation, can solve the problem of no obvious reduction in catalytic activity, achieve multiple longitudinal split opportunities, protect fibers, and surface stickiness Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

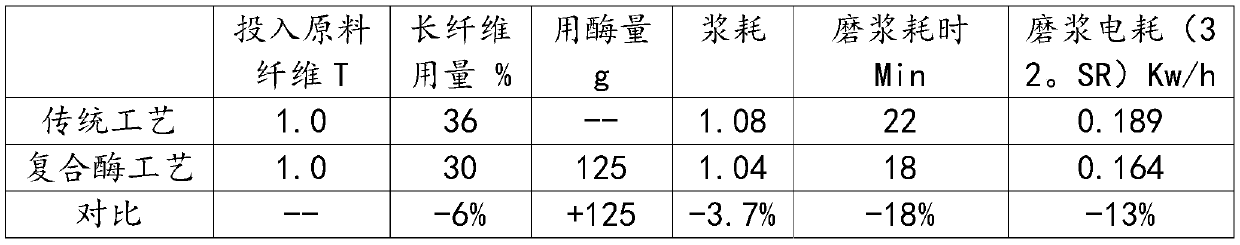

preparation example Construction

[0032] In waste paper raw materials, stickies mainly come from hot-melts, pressure-sensitive substances, sizing agents, coating stickies and ink residues in waste paper. These substances are mainly composed of polyacrylate, polyacetate, etc. Vinyl ester etc mixed with other impurities. They link together the basic structural components of the stickies through ester bonds. At the same time, due to the negative charge of the sticky matter in the pulp system, it can absorb various cationic substances, so it is easy to block the mesh, appear paper holes, produce anion garbage, cause paper breakage and paper machine damage during the pulping and papermaking process. downtime etc. The neutral esterase (Esterase) can hydrolyze polyacrylate and polyvinyl acetate to become water-soluble low-molecular-weight alcohols, thereby reducing the polymerization of stickies and achieving the purpose of decomposing stickies. In the present invention, the neutral esterase is prepared by fermenta...

example 1

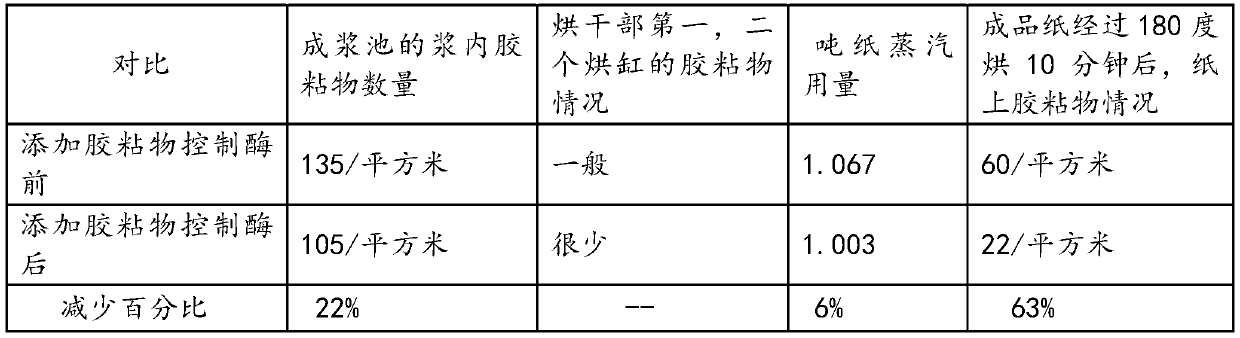

[0051] Example 1: The factory uses recycled OCC to produce liner paper, and the sticky substance control enzyme is added after refining. The effect is as follows:

[0052] Table 1: Comparison of the effects of liner paper before and after adding stickies to control enzymes

[0053]

[0054] It can be clearly seen from Table 1 that when the sticky matter control enzyme is added, the steam consumption per ton of paper drops significantly. This is because the sticky matter control enzyme hydrolyzes most of the stickies in the pulp, making the pulp The water filtration capacity is improved, and the sticky matter on the drying cylinder is reduced, thereby reducing the steam consumption per ton of paper.

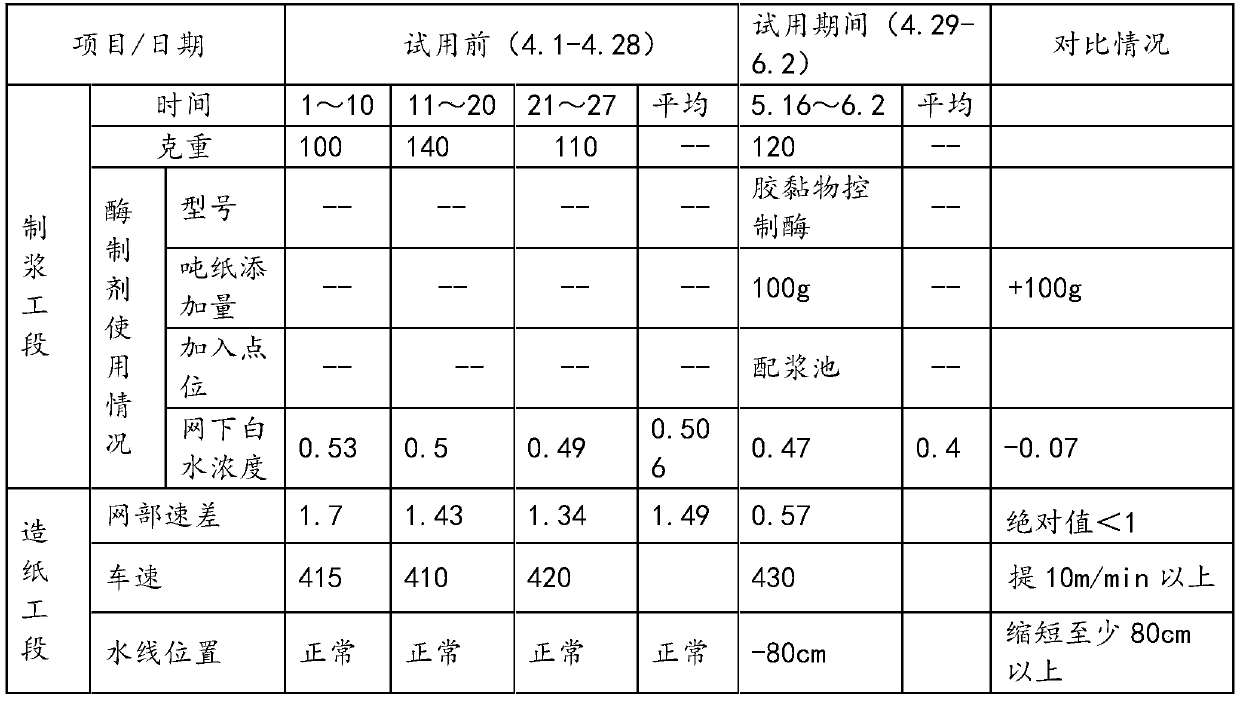

[0055] Factory application example two:

[0056] On April 28, 2017, a paper co., Ltd. in Huadu, Guangzhou began to try the sticky matter control enzyme. As of June 2, after 35 days of continuous application tests, corresponding results have been achieved. The specific applicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com