Copper alloy electroplating process

An electroplating process, copper alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of nickel layer appearance uniformity and low gloss, pitting primary battery, corrosion, etc., to ensure uniformity and gloss, enhance Corrosion resistance, effect of improving coating density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

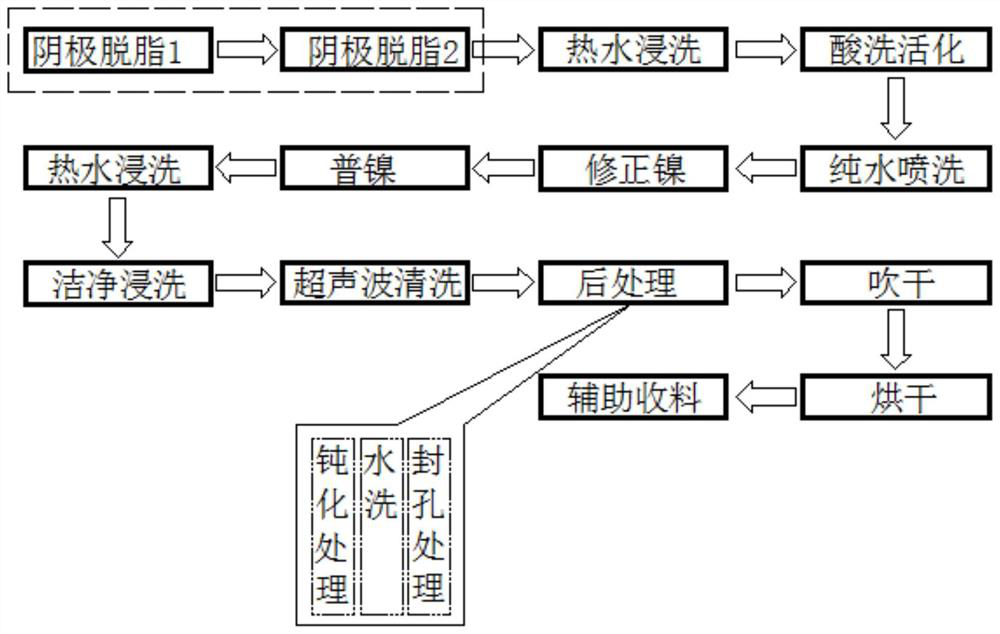

[0058] see figure 1 , copper alloy electroplating process, comprises the following steps:

[0059] Step 1, degreasing: perform mechanical polishing before degreasing the copper alloy, modify the surface of the copper alloy, provide a good electroplating plane for subsequent electroplating, and perform secondary cathodic degreasing treatment on the copper alloy successively;

[0060] The secondary cathodic degreasing uses an alkaline degreasing solution with a weight percentage of 10%. The first cathodic degreasing is at a temperature of 50°C and the current density is 5ASD, and the degreasing time is 5min. Under the condition of current density 10ASD, the degreasing time is 10min. The efficiency of electrolytic degreasing is much higher than that of chemical degreasing, and the degreasing is thorough. When the copper alloy is used as an electrode, immersed in the electrolyte, when direct current is applied, due to polarization, the metal -The interfacial tension of the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com