Preparation method of molybdenum-doped flaky cobalt diselenide/graphene composite electrode material

A graphene composite and electrode material technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of reducing electrochemical performance, reducing the number of surface active sites, and complicated preparation methods, achieving simple steps, energy saving, Avoid agglomeration phenomenon, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

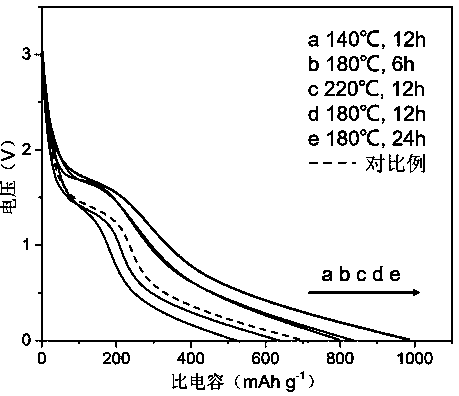

Embodiment 1

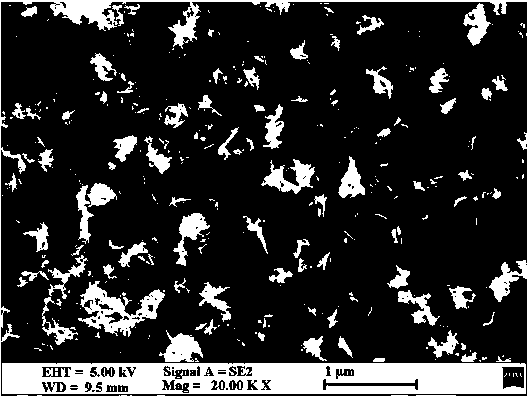

[0028] A molybdenum-doped flake CoSe 2 The preparation method of / graphene composite electrode material, concrete process is as follows:

[0029] (1) Preparation of reaction solution

[0030] Dissolve cobalt nitrate and cetyltrimethylammonium bromide in 50 mL deionized water at a molar ratio of 2:1, the molar number of cobalt nitrate is 1 mmol, and add 40 mg graphene oxide, ultrasonically disperse 1 Hour.

[0031] (2) Preparation of CoSe by hydrothermal reaction 2 Precursor

[0032] The above system was poured into a polytetrafluoroethylene reactor with a volume of 80 mL, hydrothermally reacted at 140 °C for 24 h, and the heating rate was controlled at 2 °C / min. After the reaction, the obtained product was washed with deionized water and ethanol, and dried under vacuum at 60°C.

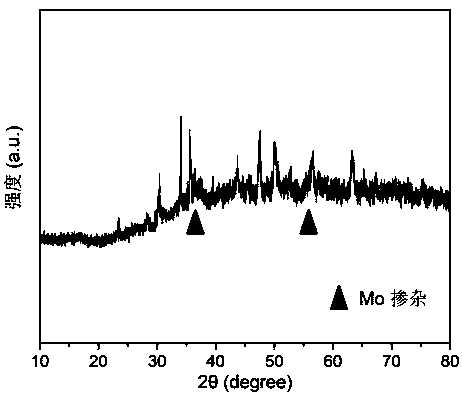

[0033] (3) Molybdenum ion doping reaction

[0034] The precursor and 0.5 mmol ammonium molybdate were placed in a porcelain boat, heated to 200 °C under an argon atmosphere, and reacted for 1 hou...

Embodiment 2

[0038] A molybdenum-doped flake CoSe 2 The preparation method of / graphene composite electrode material, concrete process is as follows:

[0039] (1) Preparation of reaction solution

[0040] Dissolve cobalt nitrate and cetyltrimethylammonium bromide in 50 mL deionized water at a molar ratio of 2:1, the molar number of cobalt nitrate is 1 mmol, and add 40 mg graphene oxide, ultrasonically disperse 1 Hour.

[0041] (2) Preparation of CoSe by hydrothermal reaction 2 Precursor

[0042] The above system was poured into a polytetrafluoroethylene reactor with a volume of 80 mL, and hydrothermally reacted at 180 °C for 24 h, and the heating rate was controlled at 2 °C / min. After the reaction, the obtained product was washed with deionized water and ethanol, and dried under vacuum at 60°C.

[0043] (3) Molybdenum ion doping reaction

[0044] The precursor and 0.5 mmol ammonium molybdate were placed in a porcelain boat, heated to 200 °C under an argon atmosphere, and reacted for 1...

Embodiment 3

[0048] A molybdenum-doped flake CoSe 2 The preparation method of / graphene composite electrode material, concrete process is as follows:

[0049] (1) Preparation of reaction solution

[0050] Dissolve cobalt nitrate and cetyltrimethylammonium bromide in 50 mL deionized water at a molar ratio of 2:1, the molar number of cobalt nitrate is 1 mmol, and add 40 mg graphene oxide, ultrasonically disperse 1 Hour.

[0051] (2) Preparation of CoSe by hydrothermal reaction 2 Precursor

[0052] The above system was poured into a polytetrafluoroethylene reactor with a volume of 80 mL, hydrothermally reacted at 220 °C for 24 h, and the heating rate was controlled at 2 °C / min. After the reaction, the obtained product was washed with deionized water and ethanol, and dried under vacuum at 60°C.

[0053] (3) Molybdenum ion doping reaction

[0054] The precursor and 0.5 mmol ammonium molybdate were placed in a porcelain boat, heated to 200 °C under an argon atmosphere, and reacted for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com