Recovery and reuse of vanadium pentoxide material in lithium ion battery

A lithium-ion battery and vanadium pentoxide technology, which is applied in battery recycling, recycling technology, secondary batteries, etc., can solve the problems of poor ion transmission capacity, high recycling cost, difficult recycling operation, etc., and achieve simple production process , high capacity, high conductivity and ion transfer rate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

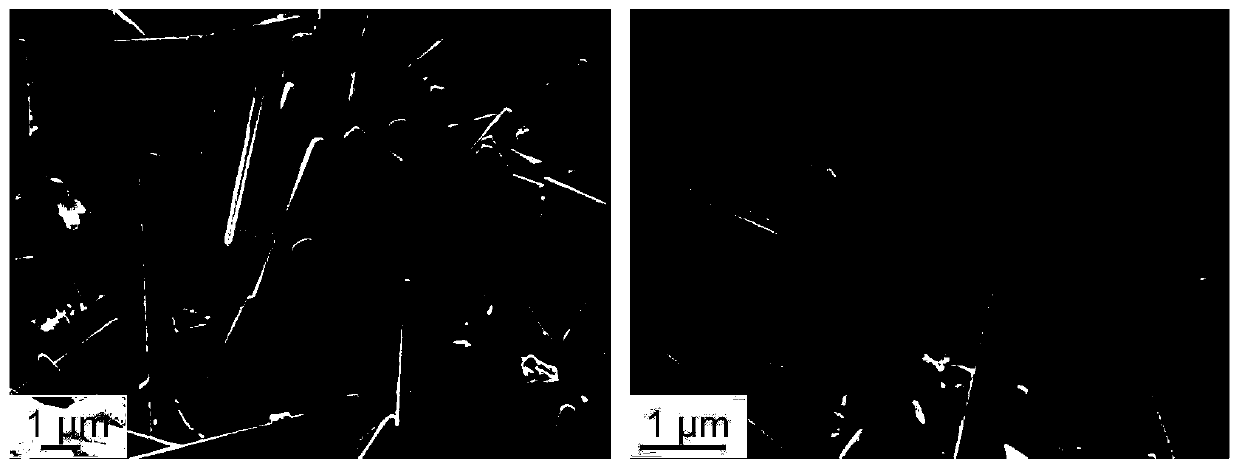

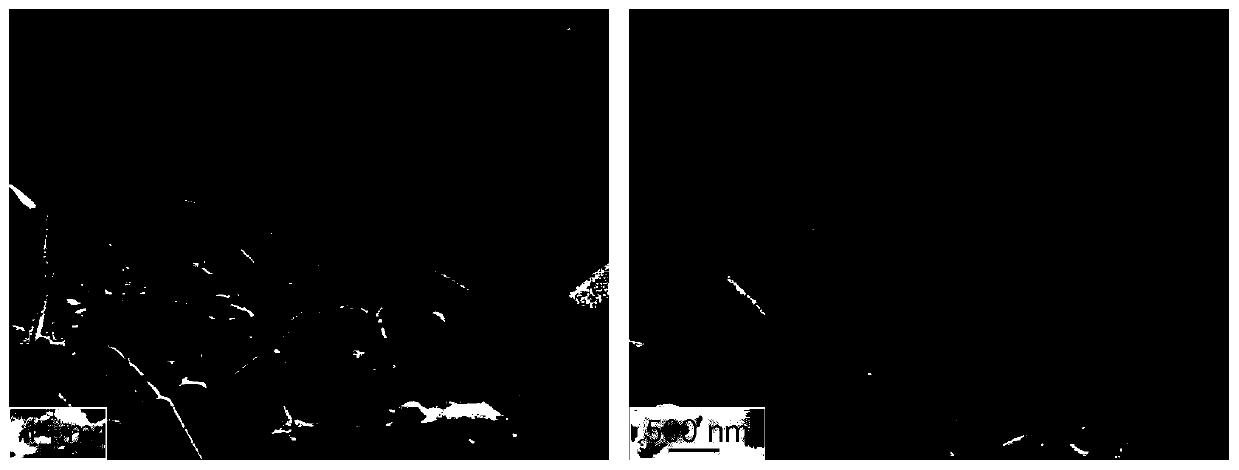

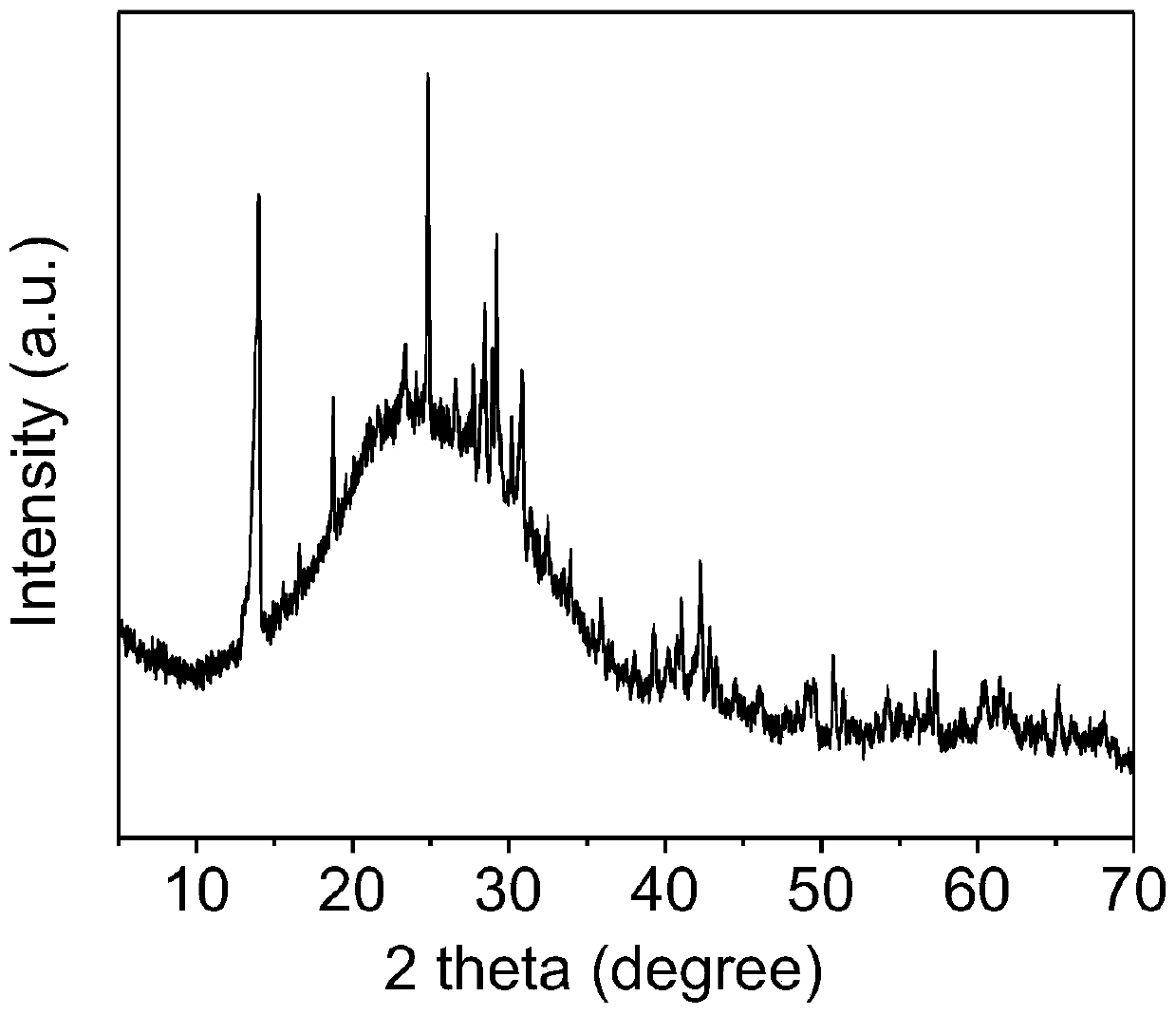

[0033] In the fume hood, use a hydraulic folding machine to disassemble the vanadium pentoxide-based waste lithium-ion battery after 10 cycles. The vanadium pentoxide material is ultrasonically cleaned with deionized water for 2 minutes, and the copper foil is taken out. Wash the vanadium pentoxide active material with water and ethanol for 2 minutes.

[0034] The vanadium pentoxide active material was heated to 500°C in a muffle furnace at 10°C min -1 Keep the heating rate for 3h, and then cool to room temperature to obtain the black recovered product lithium vanadium oxide.

Embodiment 2

[0036] In the fume hood, use a hydraulic folding machine to disassemble the vanadium pentoxide-based waste lithium-ion battery after 10 cycles. The vanadium pentoxide material is ultrasonically cleaned with deionized water for 30 seconds, and the copper foil is taken out. Wash the vanadium pentoxide active material with water and ethanol for 30s.

[0037] The vanadium pentoxide active material was heated to 500°C in a muffle furnace at 10°C min -1 Keep the heating rate for 3h, and then cool to room temperature to obtain the black recovered product lithium vanadium oxide.

Embodiment 3

[0039] In the fume hood, use a hydraulic folding machine to disassemble the vanadium pentoxide-based waste lithium-ion battery after 10 cycles. The vanadium pentoxide material is ultrasonically cleaned with deionized water for 5 minutes, and the copper foil is taken out. Wash the vanadium pentoxide active material with water and ethanol for 5 minutes.

[0040] The vanadium pentoxide active material was heated to 500°C in a muffle furnace at 10°C min -1 Keep the heating rate for 3h, and then cool to room temperature to obtain the black recovered product lithium vanadium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com