Hollow nanorobot and preparation method and application thereof as antioxidant

A hollow nano, antioxidant technology, used in chemical instruments and methods, anti-toxic agents, organic compounds/hydrides/coordination complex catalysts, etc., to achieve the effects of fast diffusion rate, large movement area, and good ROS scavenging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

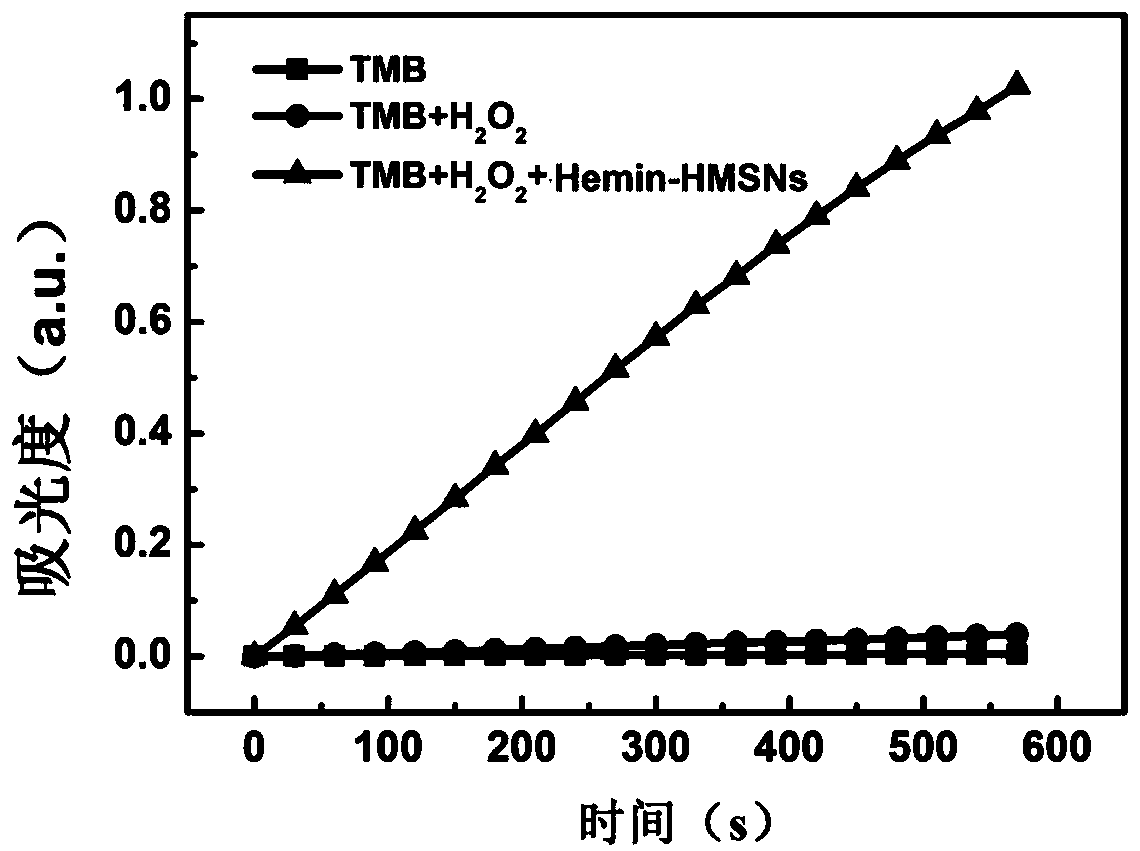

Embodiment 1

[0049] 1)SiO2 2 synthesis of balls

[0050] Add 0.3 g of cetyltrimethylammonium bromide and 2 mL of 25 wt % concentrated ammonia water to a mixed solution containing 60 mL of absolute ethanol and 100 mL of deionized water. Then, the mixture was heated to 35°C, and ethyl orthosilicate (2 mL) was added rapidly with vigorous stirring. After stirring at 35°C for 48 hours, the white product was collected by centrifugation at 5000 rpm for 10 minutes and washed three times with ethanol.

[0051] 2) Mesoporous SiO with hollow structure 2 synthesis of balls

[0052] SiO will be made 2 The spheres were dispersed in 200 mL of deionized water by sonication and aged in a water bath at 90°C for 48 hours. After the precipitate was separated by centrifugation, it was washed three times with deionized water. Disperse the precipitate in 160 mL of absolute ethanol again by sonication, add 480 μL of 37% hydrochloric acid solution, and stir at 60 °C for 3 hours to remove cetyltrimethylammoni...

Embodiment 2

[0070] 1)SiO2 2 synthesis of balls

[0071] Add 0.3 g of cetyltrimethylammonium bromide and 2 mL of 25 wt % concentrated ammonia water to a mixed solution containing 30 mL of absolute ethanol and 100 mL of deionized water. Then, the mixture was heated to 30°C, and ethyl orthosilicate (2 mL) was added rapidly with vigorous stirring. After stirring at 35°C for 48 hours, the white product was collected by centrifugation at 5000 rpm for 10 minutes and washed three times with ethanol.

[0072] 2) Mesoporous SiO with hollow structure 2 synthesis of balls

[0073] SiO will be made 2 The spheres were dispersed in 200 mL of deionized water by sonication and aged in a water bath at 90°C for 48 hours. After the precipitate was separated by centrifugation, it was washed three times with deionized water. The precipitate was again dispersed in 160 mL of absolute ethanol by sonication, 500 μL of 37% hydrochloric acid solution was added, and stirred at 60 °C for 4 hours to remove cetylt...

Embodiment 3

[0079] 1)SiO2 2 synthesis of balls

[0080] Add 0.4 g of cetyltrimethylammonium bromide and 3 mL of 25 wt % concentrated ammonia water to a mixed solution containing 50 mL of absolute ethanol and 120 mL of deionized water. Then, the mixture was heated to 30°C, and ethyl orthosilicate (3 mL) was added rapidly with vigorous stirring. After stirring at 45°C for 48 hours, the white product was collected by centrifugation at 5000 rpm for 10 minutes and washed three times with ethanol.

[0081] 2) Mesoporous SiO with hollow structure 2 synthesis of balls

[0082] SiO will be made 2The spheres were dispersed in 200 mL of deionized water by sonication and aged in a water bath at 70°C for 48 hours. After the precipitate was separated by centrifugation, it was washed three times with deionized water. Disperse the precipitate in 160 mL of absolute ethanol again by sonication, add 500 μL of 37% hydrochloric acid solution, and stir at 60 °C for 4 hours to remove hexadecyltrimethylamm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com