Method for preparing tetracarboxylic acid with regular crystal shape

A technology of tetracarboxylic acid and crystals, which is applied in the field of special engineering plastic monomer synthesis, can solve problems affecting the quality of polyimide products, and achieve the effects of increasing safety, improving acidification degree, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

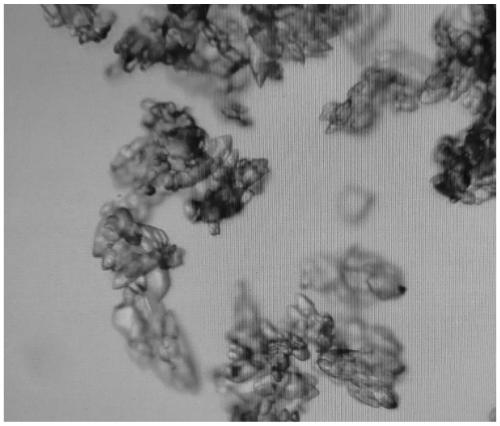

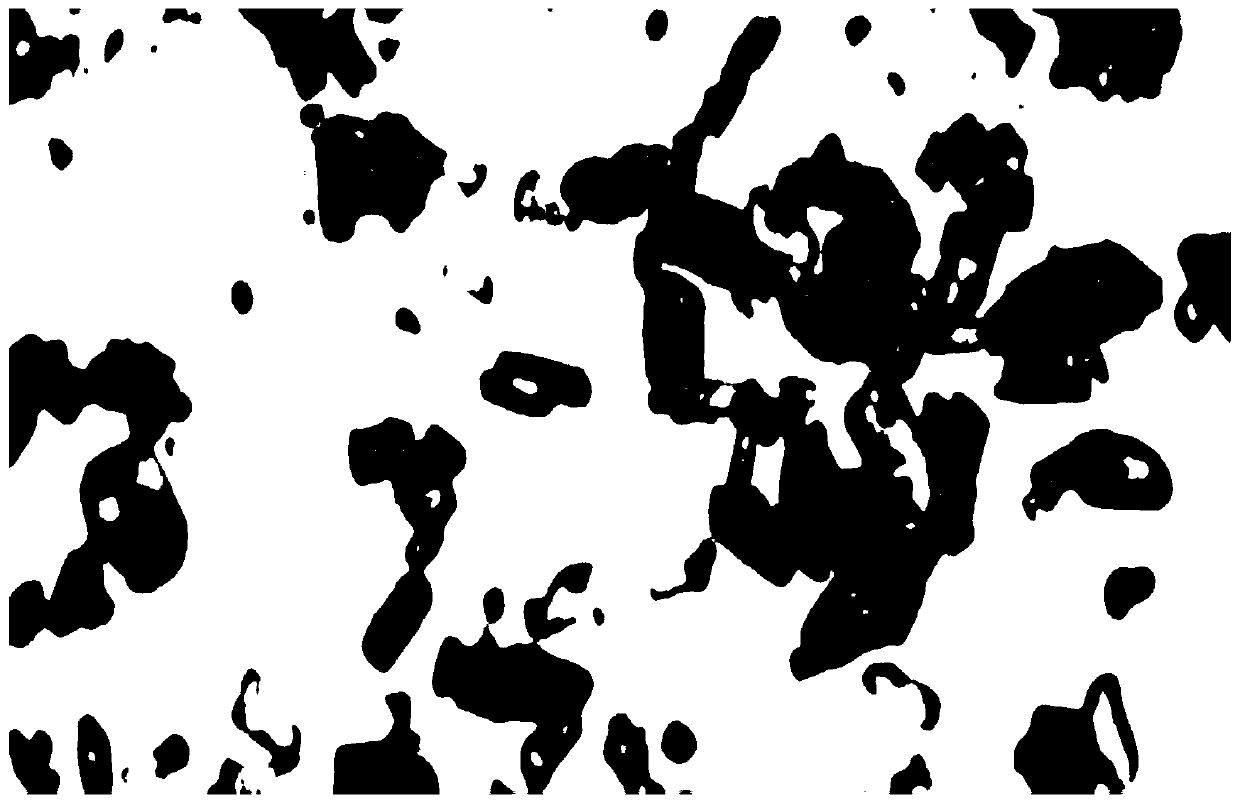

[0044] In a reactor with a spherical condenser and a fractionation column with a reflux ratio controller, slowly and continuously add 24 wt% of bisphenol A type diether to 140 g of 98 wt % concentrated sulfuric acid at a temperature of 60 ° C Aqueous solution of tetra-substituted sodium salt of tetracarboxylic acid (bisphenol A type bis-ether tetra-substituted sodium salt of tetracarboxylic acid 225.4g (molecular weight 608), water 700g), the temperature of the whole process of adding is 100°C, and the time of adding is 30min. A dispersed granular solid gradually formed under stirring.

[0045] When the amount of bisphenol A type diether tetracarboxylic acid tetrasubstituted sodium salt solution is 35% of the total amount, 1.47 g of sorbitan lauryl ester is added at one time, and 293 g of acetonitrile is added to the system, and the addition time is 10 minutes , after adding acetonitrile, keep the acetonitrile in a continuous total reflux state. Continue to slowly add the aqueo...

Embodiment 2

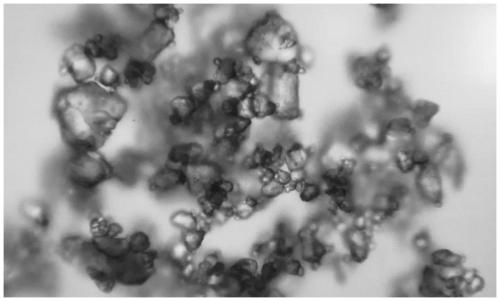

[0047] In a reactor with a spherical condenser and a fractionation column with a reflux ratio controller, slowly and continuously add 25 wt% of hydroquinone-type bis- Aqueous solution of tetra-substituted sodium ether tetracarboxylic acid (hydroquinone-type bis-ether tetra-substituted sodium salt 233g (molecular weight: 526), water 700g), the temperature of the whole process is 105°C, and the time of adding is 40min. A dispersed granular solid gradually formed under stirring.

[0048] When the hydroquinone-type bis-ether tetracarboxylic acid tetra-substituted sodium salt solution was added in an amount of 50% of the total amount, 2.10 g of nonylphenol polyoxyethylene ether was added at one time, and 350 g of acetonitrile was added to the system, and the addition time was 15 minutes. After adding acetonitrile, keep the acetonitrile in a continuous total reflux state. Continue to slowly add the aqueous solution of hydroquinone type bis-ether tetracarboxylic acid tetra-substit...

Embodiment 3

[0051] In a reactor with a spherical condenser and a fractionation column with a reflux ratio controller, slowly add 20 wt% of hydroquinone-type bis-ether four Aqueous solution of tetrasubstituted sodium salt of formic acid (175 g of tetrasubstituted sodium salt of hydroquinone type bisether tetracarboxylic acid, 700 g of water), the temperature of the whole process of adding drops is 70°C, and the time of adding drops is 45 minutes. A dispersed granular solid gradually formed under stirring.

[0052] When the hydroquinone-type bis-ether tetracarboxylic acid tetra-substituted sodium salt solution was added in an amount of 30% of the total amount, 8.4 g of Rubrakine A was added at one time, and 210 g of acetonitrile was added to the system, and the addition time was 20 minutes. After adding acetonitrile, Keep acetonitrile under continuous total reflux. Continue to slowly add the aqueous solution of hydroquinone type bis-ether tetracarboxylic acid tetra-substituted sodium salt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com