Isocyanate with inflaming retarding characteristic and preparation method and application thereof

A technology of isocyanate and diisocyanate, applied in the field of isocyanate and its preparation, can solve problems such as the flame retardancy of modified isocyanate, and achieve the effects of increasing flame retardancy, novel structure and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

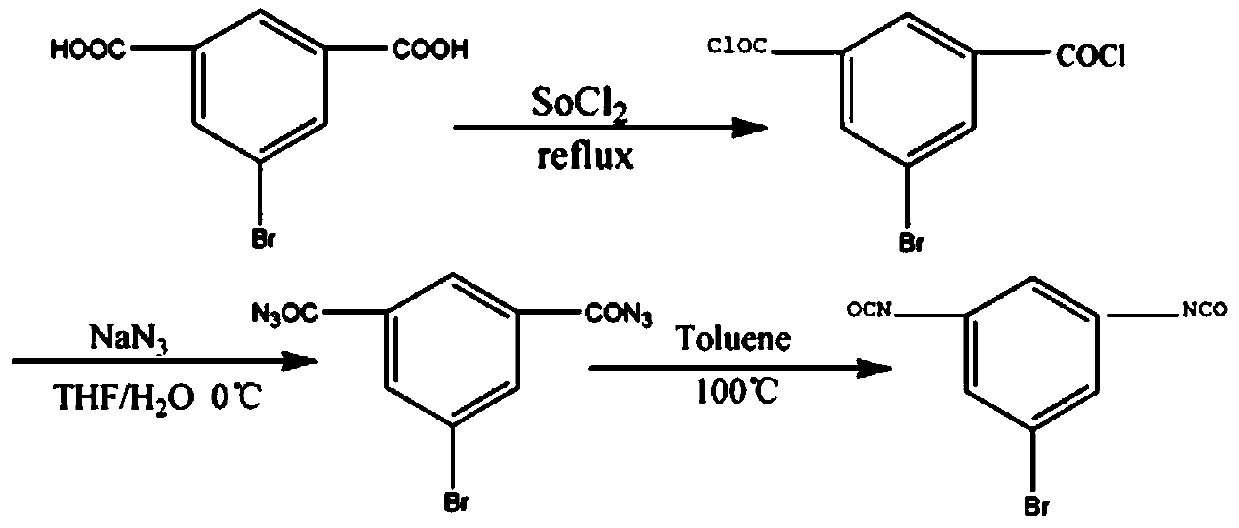

[0037] There is the preparation method of the isocyanate of flame retardant characteristic among the present invention, comprises the following steps:

[0038] (1) Preparation of 5-bromo-isophthaloyl chloride: 5-bromo-isophthalic acid in SOCl 2 Medium reflux reaction, and then evaporated under reduced pressure to remove SOCl 2 , to obtain 5-bromo-isophthaloyl chloride;

[0039] (2) Preparation of 5-bromo-isophthaloyl diazide: Dissolve 5-bromo-isophthaloyl dichloride in THF, then add NaN 3 , then add saturated NaHCO to the mixed solution 3 , extracted with toluene, the organic layer was dried and evaporated under reduced pressure to obtain a toluene solution of 5-bromo-m-dibenzoyldiazide;

[0040] (3) Preparation of 1-bromo-3,5-diisocyanatobenzene: reflux the toluene solution of 5-bromo-m-dibenzoyldiazide obtained in the above step (2), remove toluene, and obtain 1-Bromo-3,5-diisocyanatobenzene.

[0041] However, the inventor found in the synthesis process that the purity ...

Embodiment 1

[0043] An isocyanate with flame retardant properties, its structural name is 1-bromo-3,5-diisocyanatobenzene, and its structural formula is:

[0044]

[0045] The preparation method of the above-mentioned isocyanate with flame retardant properties, its preparation steps are:

[0046](1) Preparation of 5-bromo-isophthaloyl chloride: 5-bromo-isophthalic acid in SOCl 2 Medium (the mass concentration of 5-bromo-isophthaloyl chloride is 0.067mol / L) was refluxed for 2 hours, and the SOCl was distilled off under reduced pressure. 2 , to obtain the product 5-bromo-isophthaloyl chloride.

[0047] (2) Preparation of 5-bromo-isophthaloyl diazide: Dissolve 5-bromo-isophthaloyl chloride in THF (short for tetrahydrofuran) (it can be completely dissolved), and add NaN to the mixed solution 3 (NaN 3 The concentration of the substance is 0.07mol / L). Then add saturated NaHCO to the mixed solution 3 , extracted 3 times with toluene, and the organic layer was washed with MgSO 4 Drying an...

Embodiment 2

[0050] First, the preparation of 5-bromo-isophthalic acid in the present embodiment, using isophthalic acid as a raw material, utilizes liquid bromine to carry out bromination reaction to obtain 5-bromo-isophthalic acid (see Mark Gelmont for specific steps and Jakob Oren, Organic Process Research & Development 2002, 6, 591-596).

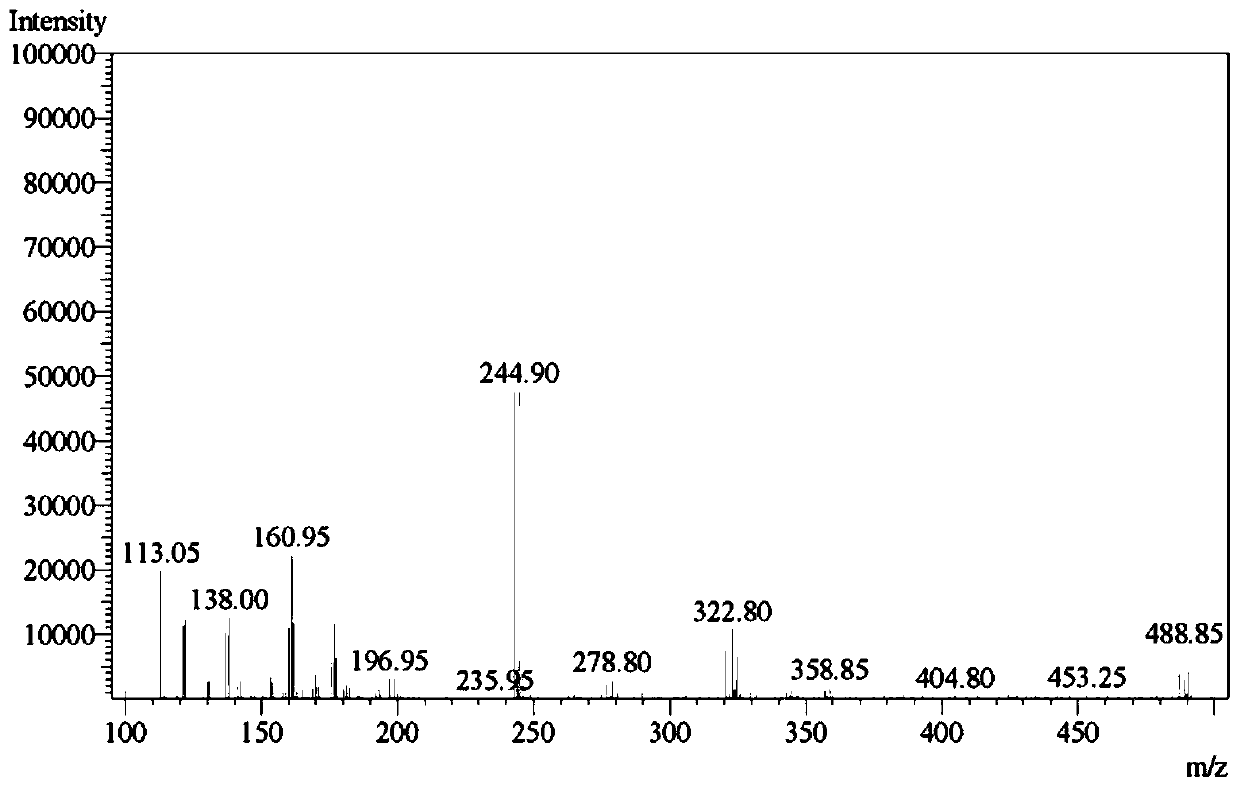

[0051] Such as figure 2 Shown is the mass spectrum of 5-bromo-isophthalic acid. Wherein the highest peak is at 244.9, which is the molecular weight of 5-bromo-isophthalic acid, indicating that the product 5-bromo-isophthalic acid has been successfully prepared. In addition, some miscellaneous peaks are ion fragments, and the peak at 322.8 is Bromine disubstitution.

[0052] In this embodiment, the isocyanate with flame retardant properties, that is, the preparation steps of 1-bromo-3,5-diisocyanatobenzene are as follows:

[0053] (1) Preparation of 5-bromo-isophthaloyl chloride: 5-bromo-isophthalic acid in SOCl 2 Medium (the mass concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com