Graphene aggregate with high specific surface area and preparation method thereof, graphene conductive electrostatic coating and preparation method thereof

A high specific surface area, graphene technology, applied in conductive coatings, coatings, etc., can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0093]As a first embodiment of the present invention, a graphene aggregate with a high specific surface area is provided, and the aggregate includes graphene, a dispersant, a stabilizer and a solvent with a low volatilization rate. Wherein, the content of graphene is 10wt%-30wt%, for example: 10wt%, 11wt%, 12wt%, 15wt%, 18wt%, 20wt%, 22wt%, 25wt%, 28wt%, 29wt%, 30wt%, etc. The content of dispersant is 10wt%-30wt%, for example: 10wt%, 11wt%, 12wt%, 15wt%, 18wt%, 20wt%, 22wt%, 25wt%, 28wt%, 29wt%, 30wt%, etc. The content of the stabilizer is 0.1wt%-10wt%, for example: 0.1wt%, 0.2wt%, 0.3wt%, 0.5wt%, 0.8wt%, 1.0wt%, 2wt%, 3wt%, 5wt%, 8wt%, 9wt%, 9.2wt%, 9.5wt%, 9.8wt%, 9.9wt%, etc. The content of low volatilization rate solvent is 30wt%-80wt%, for example: 30wt%, 31wt%, 32wt%, 34wt%, 36wt%, 38wt%, 40wt%, 42wt%, 45wt%, 48wt%, 50wt%, 52wt% , 55wt%, 58wt%, 60wt%, 62wt%, 65wt%, 68wt%, 70wt%, 72wt%, 75wt%, 78wt%, 79wt%, 80wt%, etc. The specific surface area of graphene is greater...

Embodiment 1A

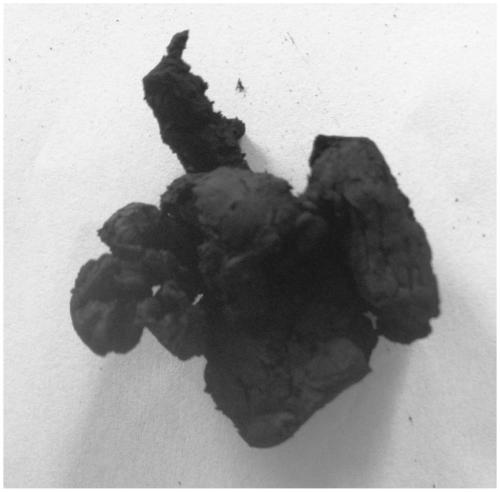

[0107] This example shows a preparation process of graphene aggregates with high specific surface area.

[0108] Step 1): Provide the following raw materials:

[0109] Graphene (specific surface area is 463m 2 / g) 2kg

[0110] Acrylate block copolymer 2kg

[0111] Bentonite 0.1kg

[0112] Absolute ethanol 95.9kg

[0113] Step 2): Prepare the first solution:

[0114] Mix graphene, acrylate block copolymer, bentonite and absolute ethanol, put the mixed solution in a disperser and stir for 20 minutes, the disperser speed is 800rpm; then use a horizontal sand mill to grind to the particle size Less than 10 μm, the first solution is obtained.

[0115] Step 3): Prepare the second solution:

[0116] Choose diethylene glycol butyl ether to mix with the first solution as low volatilization rate solvent, the mass ratio of the first solution and diethylene glycol butyl ether is 100:2.6, then the mixing of diethylene glycol butyl ether and the first solution The solution was place...

Embodiment 1B

[0119] This embodiment shows the method for preparing graphene conductive electrostatic coating by using the high specific surface area graphene aggregates prepared by the method of Example 1A.

[0120] Step 1): Mix the following ingredients:

[0121] Acrylic resin solution 120g

[0122] Cellulose acetate butyrate solution 16g

[0124] High specific surface area graphene aggregates 2g

[0126] Leveling agent 0.2g

[0127] Butyl acetate 30g

[0128] Xylene 28.8g

[0129] Wherein, the acrylic resin in the acrylic resin solution accounts for 50 wt%, and the solvent in the acrylic resin solution is xylene. The cellulose acetate butyrate accounts for 20 wt% of the cellulose acetate butyrate solution, and the solvent is butyl acetate.

[0130] Step 2): The mixed solution obtained in step 1) was placed in a disperser and stirred for 1 hour, and the rotational speed of the disperser was 1500 rpm to obtain an electrostatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com