Mildew-proof water-resistant seedling pulp molded product and preparation method and application thereof

A technology of pulp molding and products, applied in the fields of application, non-woody plant/crop pulp, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problem of affecting the quality of seedlings, prone to mildew, and soft seedling cups and other problems, to achieve good anti-mildew effect, easy to degrade, and reduce the effect of ecological environment pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The modified polyvinyl alcohol fibers used in the examples of the present application are prepared by the following method:

[0050] Add 150mL of distilled water, 8g of polyvinyl alcohol fibers and 40mL of glycidyl methacrylate into a three-neck flask, adjust to acidity, and then stir to obtain a uniformly dispersed polyvinyl alcohol fiber suspension. Then add 30 mL of acid cerium ammonium nitrate (CAN) solution with a solid content of 1% to the system, and react in a constant temperature water bath at 40° C. for 3 h. The product is filtered, washed, extracted with acetone to remove the homopolymer on the surface of the fiber, and dried in vacuum at 40°C to constant weight to obtain the modified polyvinyl alcohol fiber.

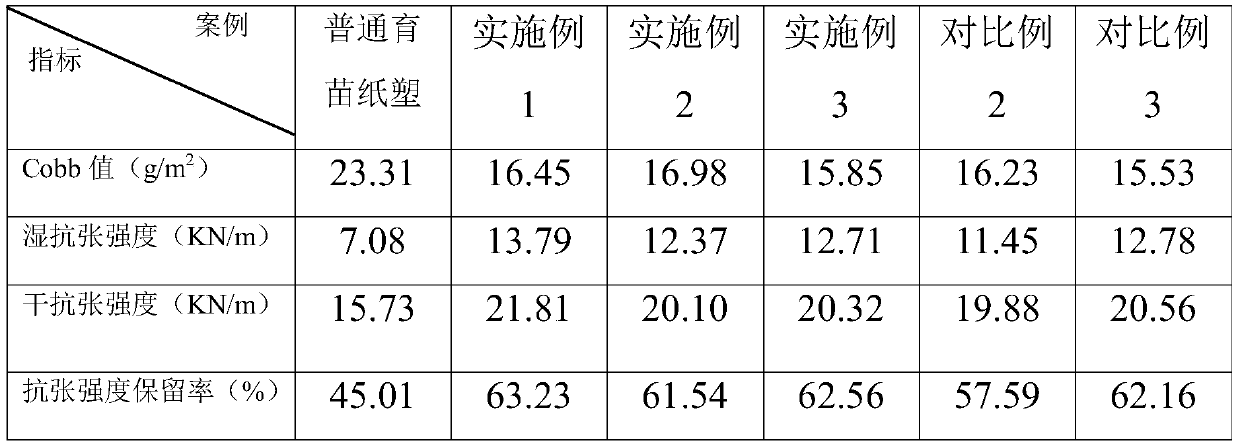

Embodiment 1

[0052] 1. Add 10g of montmorillonite to 2 times the mass of water to dissolve, add 1g of 2-methyl-4-isothiazolin-3-one and 1g of 2-methyl-5-chloro-4-isothiazolin under stirring conditions imidazol-3-one and 4g tea polyphenols to obtain a mixed solution, the mixed solution was concentrated in vacuum (50°C), and freeze-dried (at a temperature of -30°C, for 2 hours, to completely remove water), to obtain a fungicide;

[0053] 2. Mix 0.16g of antifungal agent with 8g of disintegrated and dispersed natural bamboo pulp (absolutely dry) beaten to 28°SR, 0.08g of modified polyvinyl alcohol fiber (water melting temperature 90°C) and 0.04g of PAE wet strength agent Mixing, and finally hot pressing (temperature 160°C, time 60s) to obtain a dry blank of pulp molded product after shaping and trimming;

[0054]3. Evenly coat 8.4g (the 8.4g spray liquid contains 8g distilled water, 0.24g cationic starch and 0.16g polyvinyl alcohol) spray solution on the surface of the dry base of the pulp pl...

Embodiment 2

[0056] 1. Add 10g of montmorillonite to 2.5 times of water to dissolve, add 1.5g of 2-methyl-4-isothiazolin-3-one, 1.5g of 2-methyl-5-chloro-4-iso Thiimidazol-3-one and 4.5g tea polyphenols to obtain a mixed solution, the mixed solution was concentrated in vacuo (60°C), freeze-dried (at a temperature of -25°C, for 3 hours, to completely remove water), and an antifungal agent was obtained;

[0057] 2. Mix 0.24g of antifungal agent with 8g of disintegrated and dispersed natural bamboo pulp (absolutely dry) beaten to 29°SR, 0.16g of modified polyvinyl alcohol fiber (water melting temperature 80°C) and 0.08g of PAE wet strength agent Mixing, and finally hot pressing (temperature 170°C, time 90s) to obtain a dry blank of pulp molded product after shaping and trimming;

[0058] 3. Evenly coat 8.48g (containing 8g distilled water, 0.32g cationic starch and 0.16g polyvinyl alcohol in the 8.48g spray liquid) on the surface of the dry base of the pulp plastic product, and dry it (at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com