Lightweight fiber laser

A technology of fiber lasers and lasers, which is applied in the field of lasers, can solve problems such as damage to laser components, large volume and weight of lasers, and bulky shell structures, so as to overcome the force of tangential and lateral offsets, improve energy conversion efficiency, The effect of strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

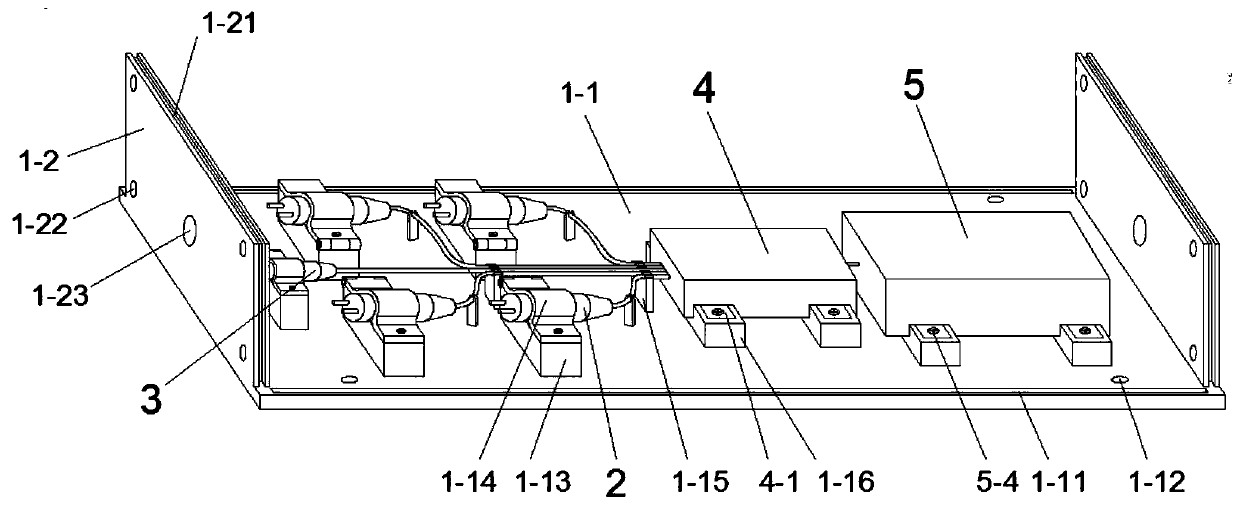

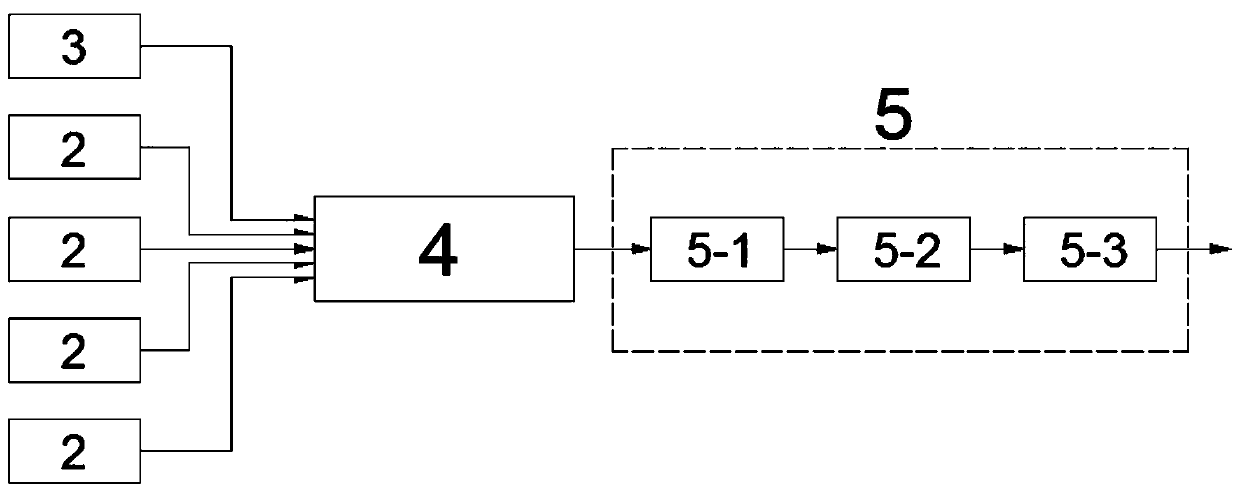

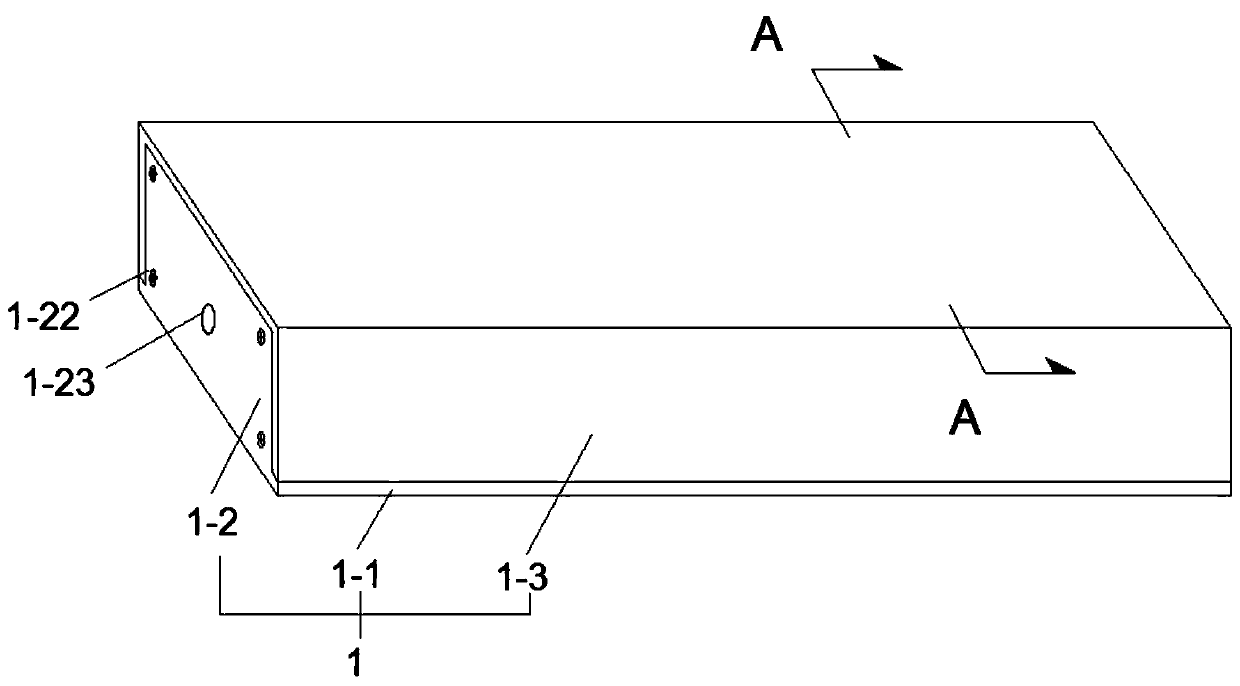

[0034] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are all known technologies known to those skilled in the art, such as welding, hot-melt one-shot molding, screw connection, bolt-nut connection, and riveting.

[0035] The semiconductor laser described in the present invention adopts a 10w fiber-coupled semiconductor laser. The emission wavelength of the laser includes two or more of 915nm, 940nm, and 976nm. The output fiber of the semiconductor laser is an optical fiber of 105um / 125um.

[0036] The red laser described in the present invention adopts a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com