Extraction method and application of active substance extracting solution

An extraction method and technology of active substances, applied in the direction of solid solvent extraction, etc., can solve problems such as toxic volatility, environmental pollution, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

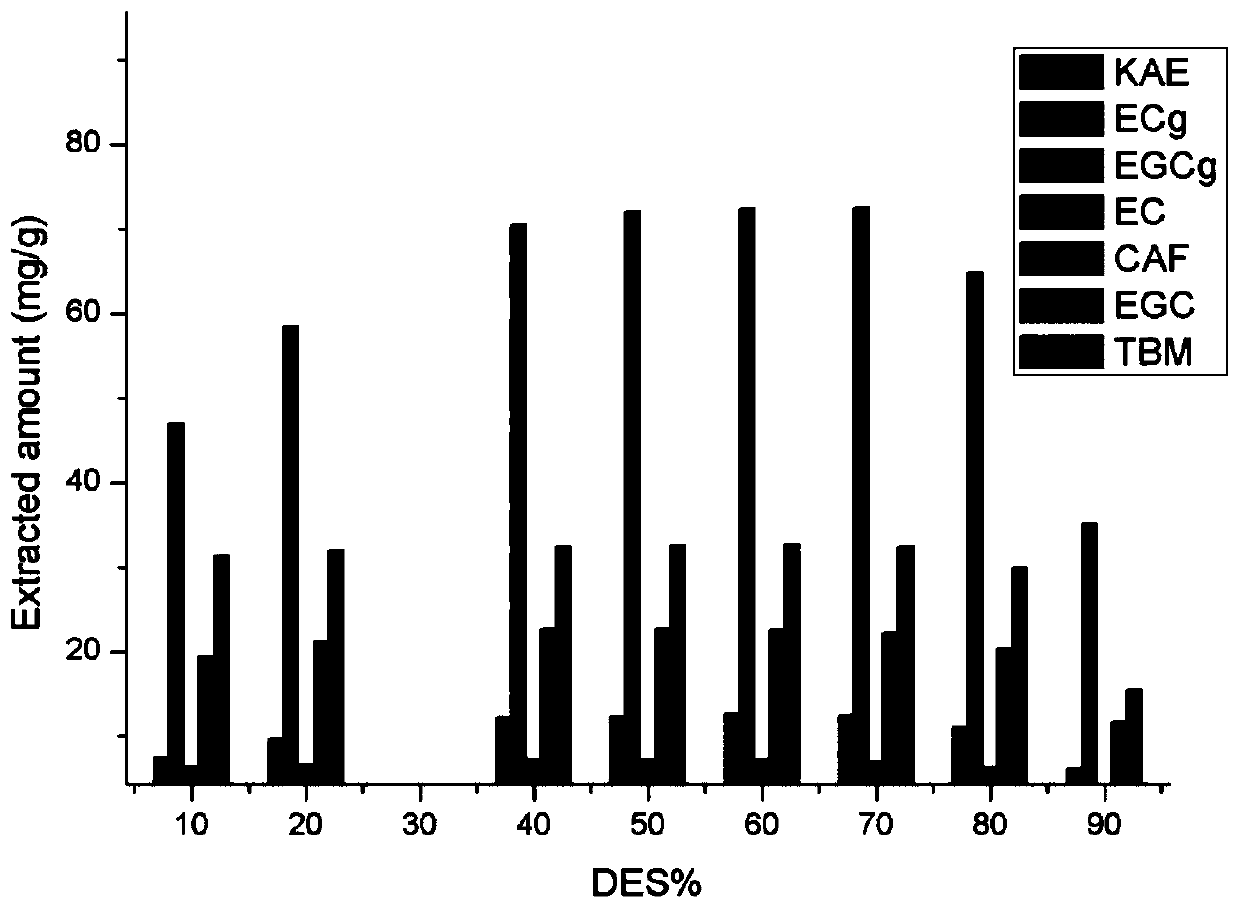

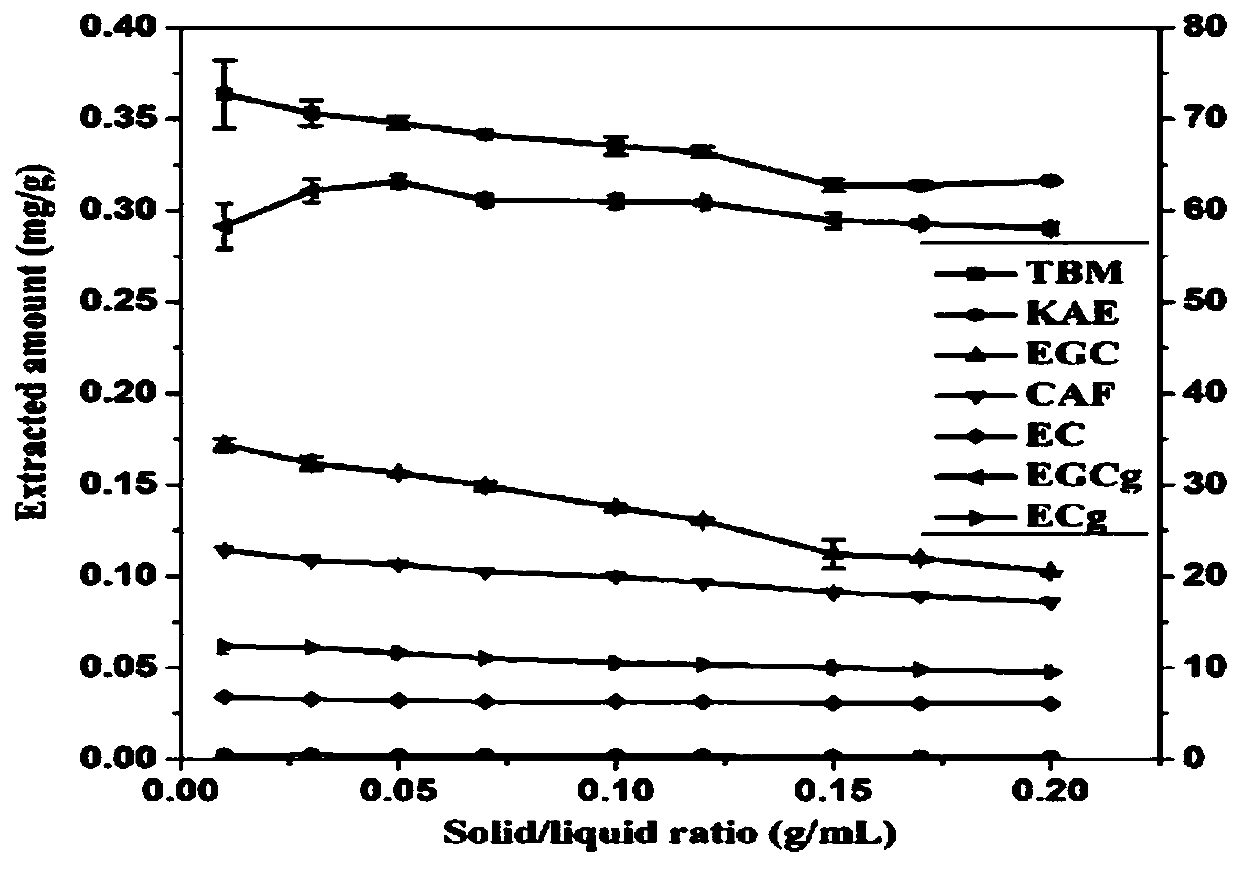

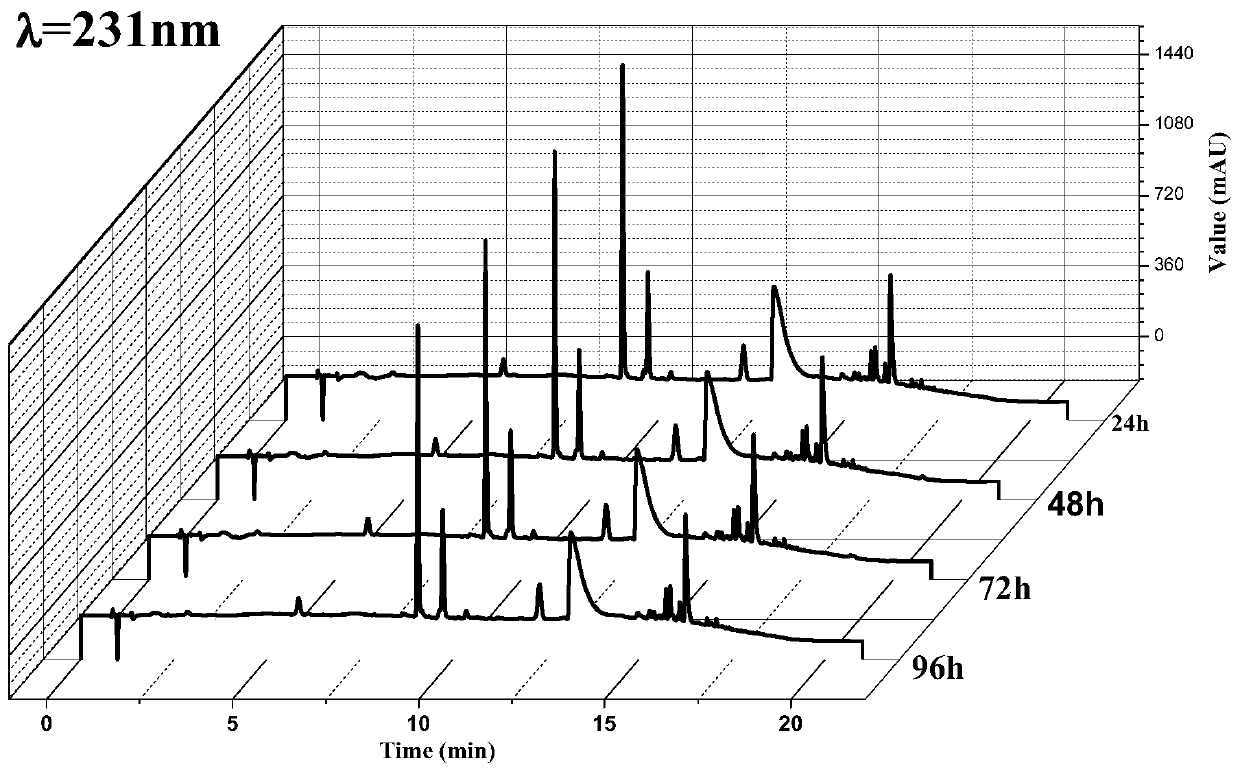

[0031] A deep eutectic solvent combined with mechanochemical extraction was used to extract alkaloids, flavonoids, and tea polyphenols from tea leaves.

[0032] (1) Target extract

[0033] Caffeine (CAF), Theobromine (TBM), Kaempferol (KAE), (-)-Epicatechin (EC), (-)-Epicatechin Gallate (ECg), (-)- Epigallocatechin (EGC) and (-)-epigallocatechinate (EGCg).

[0034] (2) Preparation of deep eutectic solvent

[0035] Heat and stir proline and glycerin with a molar ratio of 1:1-1:4 at 60-120°C for 30 minutes-2 hours to a homogeneous phase, and then dilute the deep eutectic solvent with water to 10-90% (mass percentage ).

[0036] Of course, the deep eutectic solvent of this embodiment can also be obtained by mixing other hydrogen bond acceptors and other hydrogen bond donors after heating, and other hydrogen bond acceptors can be quaternary ammonium salts, zwitterions, amino acids, sugars, carboxylic acids at least one of;

[0037] Other hydrogen bond donors may be at least o...

Embodiment 2

[0051] Deep eutectic solvent extracts are used to process liquid soaps1.

[0052] (1) Making soap paste

[0053] Mix 85 g of coconut oil, 10 g of palm kernel oil, 5 g of cocoa butter, 18 g of potassium hydroxide, and 55 g of water and raise the temperature to 70-90 degrees until completely dissolved, and then continue heating for 2-3 hours until it becomes transparent.

[0054] (2) Soap paste dilution

[0055] 30g of soap paste, 65g of water, and 5g of deep eutectic solvent extract are mixed and poured into a pot until completely dissolved, and bottled for use.

Embodiment 3

[0057] The deep eutectic solvent extract was used to process liquid soap 2.

[0058] (1) Making soap paste

[0059] Mix 75 g of coconut oil, 10 g of olive oil, 15 g of castor oil, 24 g of potassium hydroxide, and 71 g of water and heat up to 70-90 degrees until completely dissolved, then continue heating for 2-3 hours until it becomes transparent.

[0060] (2) Soap paste dilution

[0061] 57g of soap paste, 38g of water, and 5g of deep eutectic solvent extract are mixed and poured into a pot until completely dissolved, and bottled for use.

[0062] Embodiment Three

[0063] Deep eutectic solvent extracts are used to process moisturizing lotions.

[0064] 1% paraffin, 2% beeswax, 2% lanolin, 20% liquid paraffin, 10% isotriaxane, 4% sorbitan sesquioleate, 1% sorbitan monooleate, Melt solvent (glycerin is replaced by propylene glycol) extract 7%, refined water 53%, mix and dissolve, keep 70 degrees, pour the water phase into the oil phase, emulsify with a homogenizer, and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com