Preparation method for forest nanostructure and regulation and control method for forest nanostructure

A forest and nanotechnology, applied in the field of nanometers, can solve the problems of single-layer arrangement of difficult balls, cost, and increase in process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

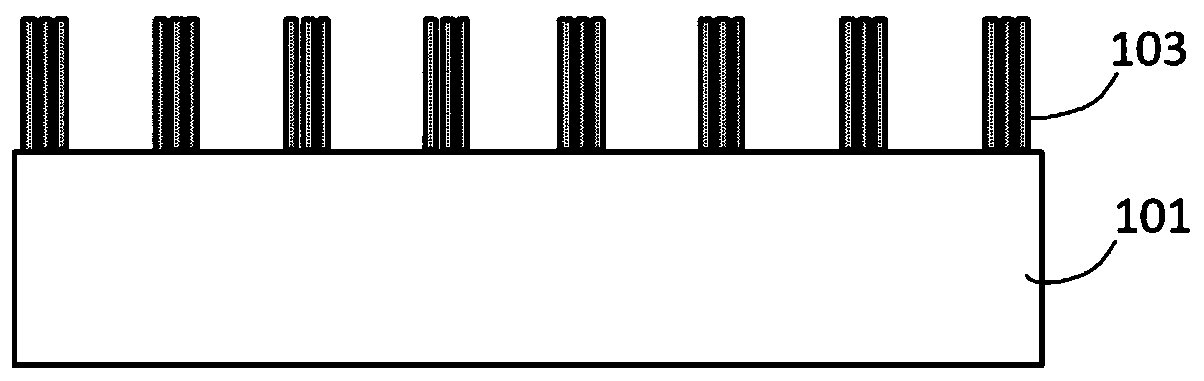

[0035] As described in the background art, due to the comprehensive consideration of nano-forest structure characteristics control, processing cost, and device integration application, it is urgent to develop a process method for preparing nano-forest structures with controllable morphology and characteristics. . The inventor of the present invention has studied the above problems and proposed a method for preparing a nano forest structure, which includes the following steps: S1, using a mixture including a coupling agent and a polymer to form a thin film layer on a substrate; S2, The thin film layer undergoes plasma bombardment to form the nano forest structure.

[0036] In the above-mentioned preparation method, a coupling agent is used as an inducer, and a nano-forest structure is prepared by using a plasma degumming process after mixing polymers. Using plasma to bombard the polymer layer can re-polymerize part of the product produced by the polymer to form a forest nanostruc...

Embodiment 1

[0054] The preparation method of the nano forest structure provided in this embodiment is as follows Figure 1 to Figure 3 As shown, including the following steps:

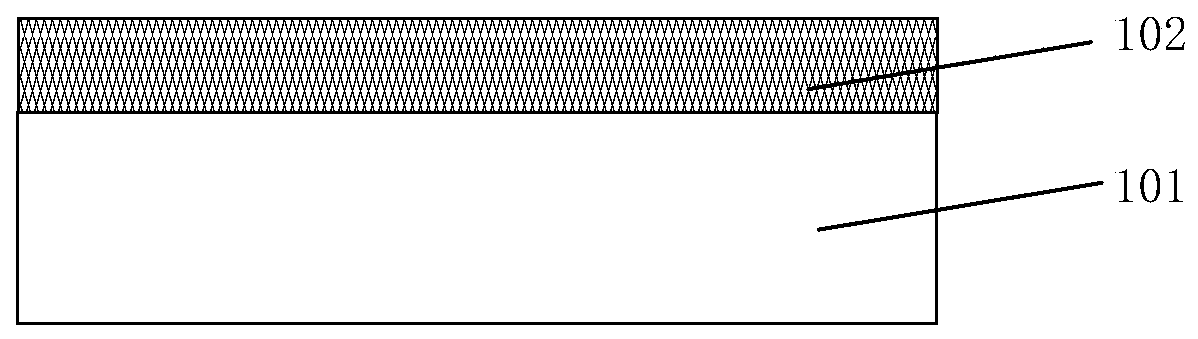

[0055] A substrate 101 is provided, and the substrate 101 is a single crystal silicon wafer;

[0056] Provide a mixture of coupling agent and polymer, wherein the coupling agent in the mixture is a coupling agent containing epoxy groups, and the polymer is a polyimide photoresist. The ratio of the two is 1:10. In a normal temperature and normal pressure yellow light environment, use a stir bar to mix the coupling agent and photoresist for 10 minutes, and let it stand for 30 minutes;

[0057] The mixture is spin-coated on the substrate 101 by spin coating. During the process, a low speed of 750 rpm is used for 8 seconds, and then a high speed of 4000 rpm is used for 25 seconds to form a film layer with a thickness of 8 μm. The substrate 101 of the spin-coated mixture is placed on a hot plate for baking, the baking tempe...

Embodiment 2

[0060] The difference between the preparation method of the nano forest structure provided in this embodiment and the embodiment 1 is:

[0061] The plasma gas source is argon gas, the flow rate of argon gas during the bombardment process is 20 sccm, the cavity pressure is 2 Pa, the time is 60 minutes, and the cavity power is maintained at 200 W during the entire bombardment process. After the bombardment process is over, the bottom of the nano-forest structure shrinks and gathers to form a thicker nano-fiber forest structure 104 with a height of about 4 μm, such as Figure 4 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com