A controlled approach to promote Fenton oxidation mediated by complexes of calcium and organic acids

A technology of Fenton oxidation and control method, which is applied in chemical instruments and methods, water treatment parameter control, special compound water treatment, etc., can solve the problems of large dosage of chemicals, high input cost and low reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

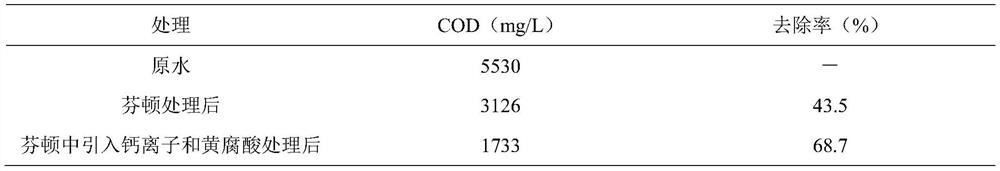

Embodiment 1

[0048] This embodiment is aimed at the high-concentration organic wastewater in the pharmaceutical industry, adopting the comparative test of the treatment method of the present invention and the Fenton treatment method in the prior art, and the specific steps are as follows:

[0049] (1) Take 2L of high-concentration organic wastewater from the pharmaceutical industry, the COD concentration in the raw water is 5530mg / L, the pH of the wastewater is in a neutral state, and the salt content is about 0.6%.

[0050] Sulfuric acid was used to adjust the pH of the waste water to 2. Take 1 L of waste water in two beakers, add 10 g of hydrogen peroxide with a mass concentration of 27%, and add 2.5 g of ferrous sulfate.

[0051] (2) add calcium chloride and fulvic acid in the waste water after step (1) treatment, according to formula C Ca =0.06×(C COD / 1000+C H ) to calculate the concentration of calcium in the wastewater, according to the formula C L =10×C Fe -0.8×C Ca Calculate ...

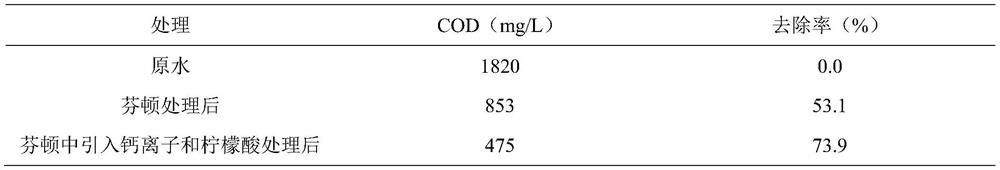

Embodiment 2

[0060] This embodiment is aimed at the organic waste water that coal chemical industry produces, adopts the comparative test of treatment method of the present invention and the Fenton treatment method in the prior art, concrete steps are as follows:

[0061] (1) Take 2L of organic wastewater produced by the coal chemical industry, the COD concentration in the raw water is 1820mg / L, the pH of the wastewater is in the range of 7-8.5, and the salt content is 0.08%.

[0062] Sulfuric acid was used to adjust the pH value of the waste water to 3. Take 1 L of waste water in two beakers respectively, add 3 g of hydrogen peroxide with a mass concentration of 27%, and add 0.75 g of ferrous sulfate.

[0063] (2) add calcium chloride and citric acid in the waste water after step (1) treatment, according to formula C Ca =0.1×(C COD / 1000+C H ) to calculate the dosing concentration of calcium chloride, according to the formula C L =6×C Fe -0.5×C Ca Calculate the concentration of citri...

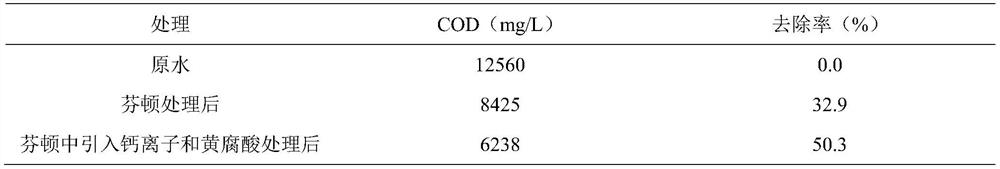

Embodiment 3

[0072] This embodiment is aimed at the organic waste water that fine chemical industry produces, adopts the comparative test of treatment method of the present invention and the Fenton treatment method in the prior art, concrete steps are as follows:

[0073] (1) Take 2L of organic wastewater produced by the fine chemical industry in a beaker. The COD concentration in the raw water is 12560mg / L, the pH of the wastewater is in the range of 7-9, and the salt content is about 1.5%.

[0074]Sulfuric acid was used to adjust the pH of the waste water to 4, and 1 L of waste water was taken in two beakers, and 20 g of hydrogen peroxide with a mass concentration of 27% and 2.5 g of ferrous sulfate were added respectively.

[0075] (2) add calcium chloride and fulvic acid in the waste water after step (1) treatment, according to formula C Ca =0.05×(C COD / 1000+C H ) to calculate the concentration of calcium, according to the formula C L =12×C Fe -1.0×C Ca Calculate the dosing conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com