Method for treating cutting fluid waste water and recovering active ingredient of cutting fluid by utilizing extraction process

A technology of active ingredients and cutting fluid, which is applied in the field of extraction method to treat cutting fluid wastewater and its active ingredients recovery, can solve the problems of not being able to obtain ideal treatment effects, achieve high environmental and economic benefits, improve use quality, and improve extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

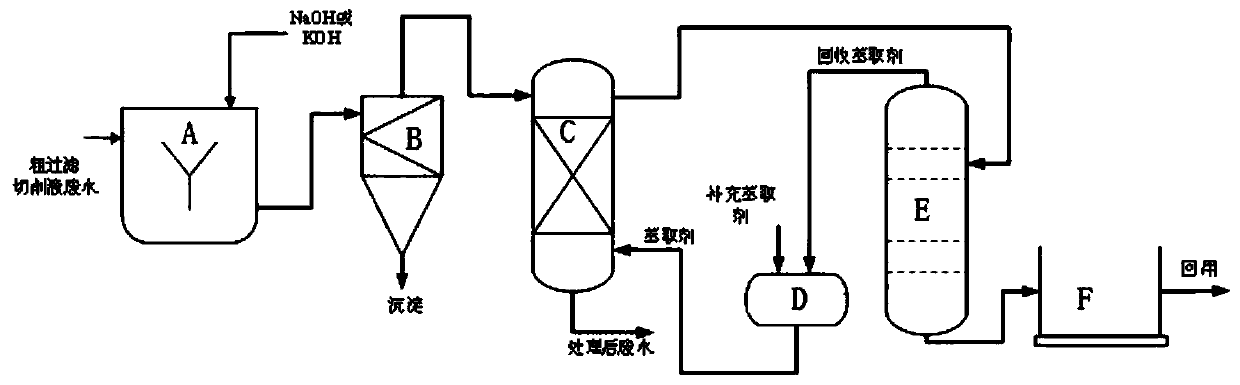

Method used

Image

Examples

Embodiment 1

[0034] A kind of method utilizing extraction method to process cutting fluid waste water and its active ingredient recovery, concrete steps are:

[0035] (1) With 20t of fresh cutting fluid waste water taken from a mechanical processing plant, after coarse filtration to remove solid precipitation, 900kgNaOH was added thereto, and stirred and demulsified in the demulsifier;

[0036] (2) Input the cutting fluid wastewater obtained after the treatment in step (1) into a high-speed centrifuge, and centrifuge for 10 minutes at a speed of 7500r / min to remove sediment;

[0037] (3) Input the cutting fluid waste water obtained after step (2) into the mixing clarifier, and add 7t of isopropyl ether to carry out the extraction operation. After standing and stratifying, the lower layer is the cutting liquid waste water after extraction, and the upper layer is A mixture of extractants and active ingredients in cutting fluid wastewater;

[0038] (4) Repeat step (3) twice for the cutting f...

Embodiment 2

[0043] A kind of method utilizing extraction method to process cutting fluid waste water and its active ingredient recovery, concrete steps are:

[0044] (1) Take 20 tons of fresh cutting fluid waste water from a certain mechanical processing plant, after coarse filtration to remove solid precipitation, add about 730kgKOH to it, and stir and break the emulsion in the demulsifier;

[0045] (2) Input the cutting fluid wastewater treated in step (1) into a high-speed centrifuge, and centrifuge for 10 minutes at a speed of 10000r / min to remove sediment;

[0046] (3) The cutting fluid waste water obtained after step (2) is processed by 2m 3 The flow rate of / h is continuously pumped from the top of the tower into the extraction tower, and the bottom of the tower is pumped into 1.0m 3 / h of petroleum ether for extraction. The discharge at the bottom of the tower is the cutting fluid waste water after extraction, and the extract produced at the top of the tower is the mixture of the...

Embodiment 3

[0051] A kind of method utilizing extraction method to process cutting fluid waste water and its active ingredient recovery, concrete steps are:

[0052] (1) Take 30t of fresh cutting fluid waste water from a machinery processing factory, after coarse filtration to remove solid precipitation, add NaOH in an amount of 60 kg per ton of water, and stir and demulsify in the demulsifier;

[0053] (2) Input the cutting fluid wastewater obtained after the treatment in step (1) into a high-speed centrifuge, and centrifuge for 10 minutes at a speed of 7000r / min to remove sediment;

[0054] (3) the cutting fluid waste water obtained after step (2) is processed by 5m 3 The flow rate of / h is sequentially pumped into three centrifugal extractors in series, and the flow rate is 2.5m 3 The flow rate per hour is sequentially pumped into n-hexane from the last extractor countercurrently to carry out the extraction operation. The waste water at the outlet of the last extractor is the cutting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com