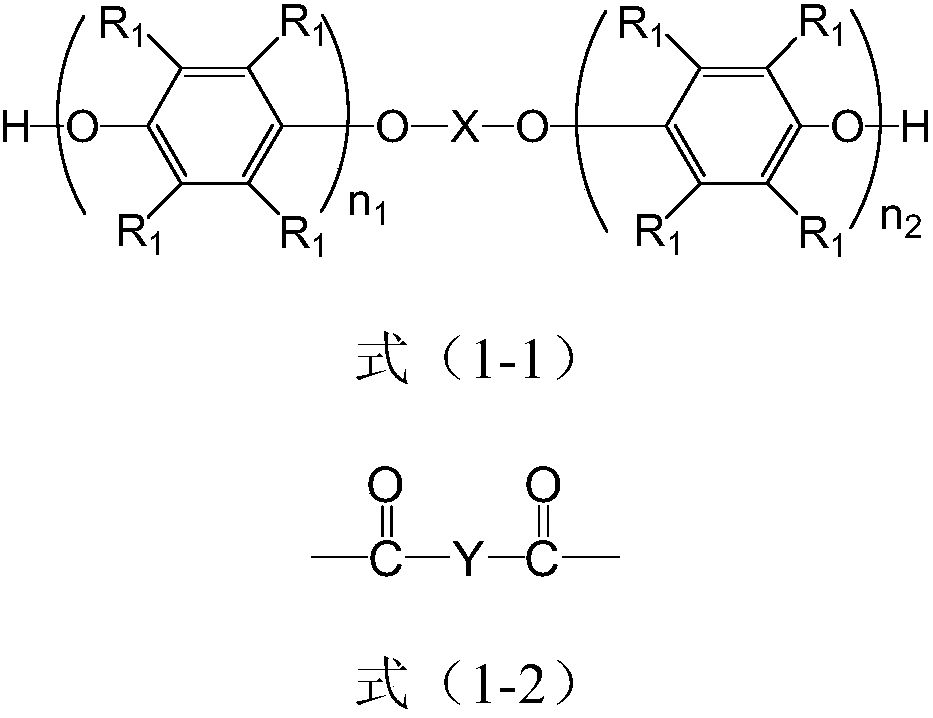

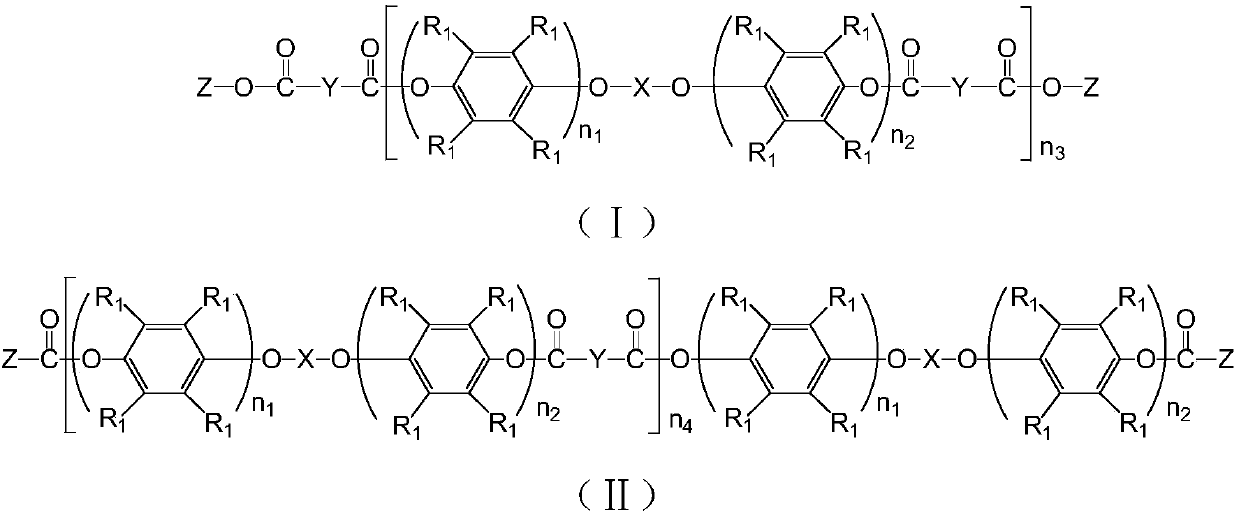

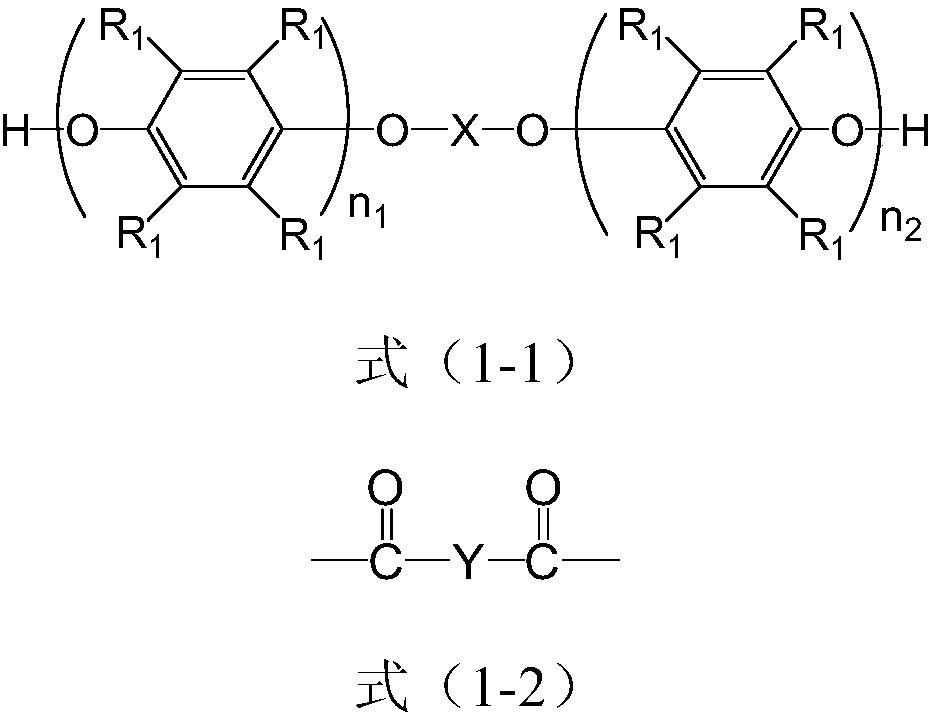

Modified polyphenylene ether resin, thermosetting resin composition and application thereof

A technology of polyphenylene ether resin and resin composition, applied in the field of polymers, can solve the problems of poor compatibility between PPO and epoxy resin, poor processability, harsh curing conditions, etc., to avoid a significant decrease in Tg and improve compatibility. Poor properties and the effect of improving cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] (1) Synthesis of modified polyphenylene ether resin of formula (I) structure

[0070] Put 1mol (425g) RPE-HL and 1500g tetrahydrofuran into a flask equipped with a thermometer, dropping funnel, and stirrer, blow in nitrogen, and stir until completely dissolved. Then, drop in 0.7mol (142.1g) isophthaloyl chloride and stir to dissolve, then, control the temperature of the system below 20°C, slowly add (more than 0.5 hours) 1.4mol (141.4g) triethylamine (prepared to 20% Triethylamine / tetrahydrofuran solution was added dropwise). Next, the stirring reaction was continued for 2.0 to 3.0 hours below 20°C. Next, 0.4 mol (37.6 g) of phenol was added, and the stirring reaction was continued for 2.0 hours below 20°C. Stand still after the reaction is complete, filter to remove the triethylamine hydrochloride solid, carry out vacuum distillation and concentration in the solution, then add methanol to separate out the resin product, filter, wash with water until the pH value of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com