Preparation method for coagulase test paper

A technology for detecting test strips and coagulation enzymes, applied in measuring devices, material analysis through observation of the influence of chemical indicators, instruments, etc., can solve the problems of complex AV scoring and discomfort in clinical routine inspections, and achieve easy operation and reduce errors , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

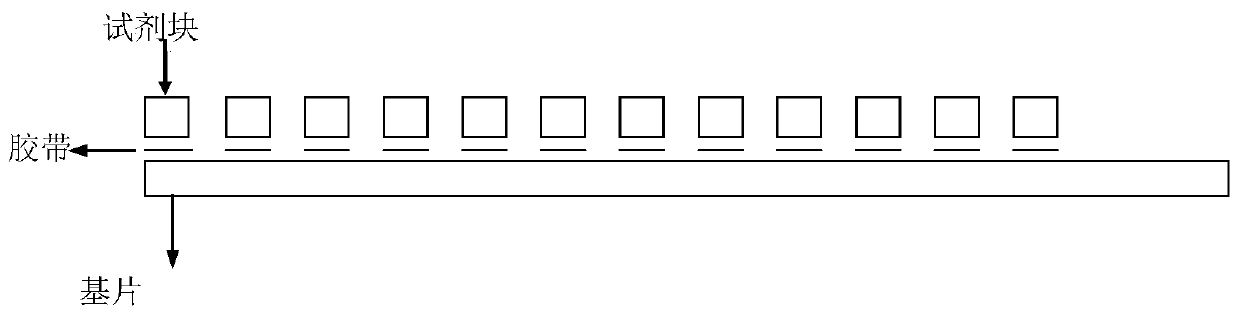

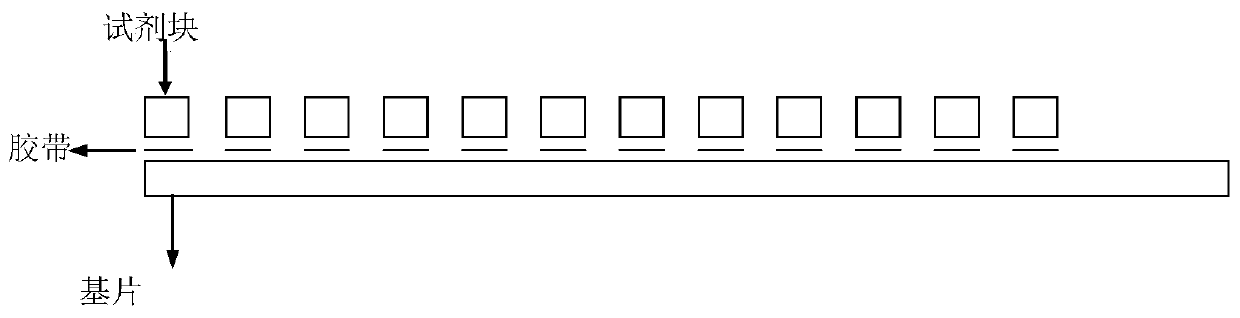

[0095] Implementation case 1: Preparation of coagulase test paper

[0096] Dip: 300mM Tris-HCl buffer;

[0097] 5.0mg / mL glycyl-arginine-4-methoxy-β-naphthylamine hydrochloride;

[0098] 3.0mg / mL trehalose;

[0099] 3.0mg / mL PEG-6000;

[0100] pH value is 8.5;

[0101] Filter paper type: 31ET filter paper

[0102] Matching color developing solution: 1.5mg / mL dimethylaminocinnamaldehyde;

[0103] 2.0mg / mL Triton X-100;

[0104] 4.0mg / mL PVP-K90;

[0105] 1000mL distilled water;

[0106] Automatic drying method of coagulation enzyme test paper impregnation dryer:

[0107] After starting up, set the equipment temperature to 80°C for the main heating and 60°C for the auxiliary heating. When the heating temperature of the host reaches 80°C, the immersion starts when the temperature of each drying chamber reaches 60°C;

[0108] Impregnation dryer speed setting: 10.0Hz.

Embodiment example 2

[0109] Implementation case 2: Preparation of coagulase test paper

[0110] Dip: 300mM Tris-HCl buffer;

[0111] 5.0mg / mL Glycyl-Arginine-β-Naphthylamine;

[0112] 3.0mg / mL trehalose;

[0113] 3.0mg / mL PEG-6000;

[0114] pH value is 8.5;

[0115] Filter paper type: 31ET type filter paper

[0116] Matching color developing solution: 1.5mg / mL dimethylaminocinnamaldehyde;

[0117] 2.0mg / mL Triton X-100;

[0118] 4.0mg / mL PVP-K90;

[0119] 1000mL distilled water;

[0120] Automatic drying method of coagulation enzyme test paper impregnation dryer:

[0121] After starting up, set the equipment temperature to 80°C for the main heating and 60°C for the auxiliary heating. When the heating temperature of the host reaches 80°C, the immersion starts when the temperature of each drying chamber reaches 60°C;

[0122] Impregnation dryer speed setting: 10.0Hz.

Embodiment example 3

[0123] Implementation case 3: Preparation of coagulase test paper

[0124] Dip: 300mM Tris-HCl buffer;

[0125] 5.0mg / mL glycyl-arginine-7-amino-4-methylcoumarin;

[0126] 3.0mg / mL trehalose;

[0127] 3.0mg / mL PEG-6000;

[0128] pH value is 8.5;

[0129] Filter paper type: 31ET type filter paper

[0130] Matching color developing solution: 1.5mg / mL dimethylaminocinnamaldehyde;

[0131] 2.0mg / mL Triton X-100;

[0132] 4.0mg / mL PVP-K90;

[0133] 1000mL distilled water;

[0134] Automatic drying method of coagulation enzyme test paper impregnation dryer:

[0135] After starting up, set the equipment temperature to 80°C for the main heating and 60°C for the auxiliary heating. When the heating temperature of the host reaches 80°C, the immersion starts when the temperature of each drying chamber reaches 60°C;

[0136] Impregnation dryer speed setting: 10.0Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com