A kind of preparation method of anti-atomization anti-fog and haze mask material

An anti-fog and mask technology, applied in the field of fabrics, can solve the problems of glasses mirror fogging, mouth and nose stuffiness, and facial stuffiness, etc., and achieve the effect of good gloss, easy fibrillation, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

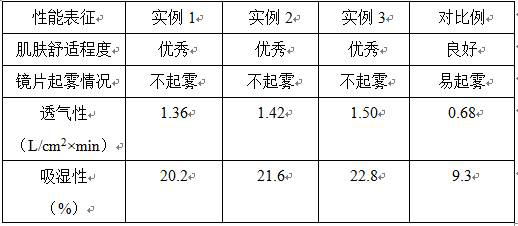

Examples

example 1

[0028] Get wood pulp, cotton pulp, N-methylmorpholine aqueous solution, superfine activated carbon, wood pulp, cotton pulp and N-methylmorpholine aqueous solution are mixed, carry out stirring treatment, obtain mixed liquid A, in Add ultra-fine activated carbon into the mixed solution A, and continue to stir for 15 minutes to obtain the mixed solution B. The mixed solution B is subjected to decompression treatment to obtain the spinning solution, and the spinning solution is subjected to spinning treatment to obtain the composite fiber; Fiber and cotton fiber are mixed at a ratio of 70%: 30% to obtain the mixed fiber, and the mixed fiber is opened, carded, drawn, spunlace, and dried to obtain the base cloth; composite fiber, polyethylene, linear Low-density polyethylene, calcium carbonate, OP-10, zinc stearate, deionized water, mix composite fiber, polyethylene, linear low-density polyethylene, calcium carbonate, OP-10, zinc stearate and deionized water , carry out high-speed ...

example 2

[0030] Get wood pulp, cotton pulp, N-methylmorpholine aqueous solution, superfine activated carbon, wood pulp, cotton pulp and N-methylmorpholine aqueous solution are mixed, carry out stirring treatment, obtain mixed liquid A, in Add ultra-fine activated carbon into the mixed solution A, and continue to stir for 17 minutes to obtain the mixed solution B. The mixed solution B is subjected to decompression treatment to obtain the spinning solution, and the spinning solution is subjected to spinning treatment to obtain the composite fiber; Fiber and cotton fiber are mixed at a ratio of 70%: 30% to obtain the mixed fiber, and the mixed fiber is opened, carded, drawn, spunlace, and dried to obtain the base cloth; composite fiber, polyethylene, linear Low-density polyethylene, calcium carbonate, OP-10, zinc stearate, deionized water, mix composite fiber, polyethylene, linear low-density polyethylene, calcium carbonate, OP-10, zinc stearate and deionized water , carry out high-speed ...

example 3

[0032] Get wood pulp, cotton pulp, N-methylmorpholine aqueous solution, superfine activated carbon, wood pulp, cotton pulp and N-methylmorpholine aqueous solution are mixed, carry out stirring treatment, obtain mixed liquid A, in Add ultra-fine activated carbon into the mixed solution A, and continue to stir for 20 minutes to obtain the mixed solution B. The mixed solution B is subjected to decompression treatment to obtain the spinning solution, and the spinning solution is subjected to spinning treatment to obtain the composite fiber; Fiber and cotton fiber are mixed at a ratio of 70%: 30% to obtain the mixed fiber, and the mixed fiber is opened, carded, drawn, spunlace, and dried to obtain the base cloth; composite fiber, polyethylene, linear Low-density polyethylene, calcium carbonate, OP-10, zinc stearate, deionized water, mix composite fiber, polyethylene, linear low-density polyethylene, calcium carbonate, OP-10, zinc stearate and deionized water , carry out high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com