Method for processing an electrode material, processed electrode material and lithium-ion battery

A lithium-ion battery and electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve good rate performance, meet the requirements of rapid charge and discharge, and improve conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

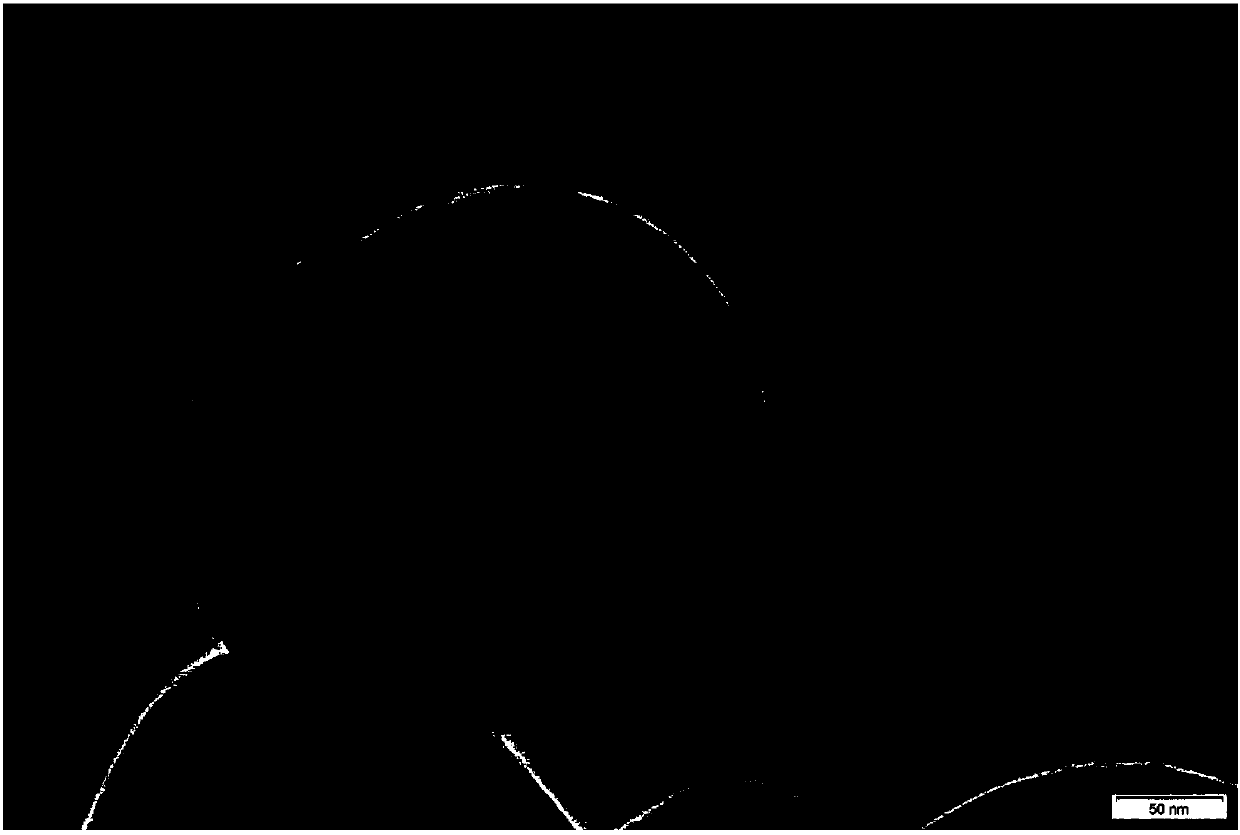

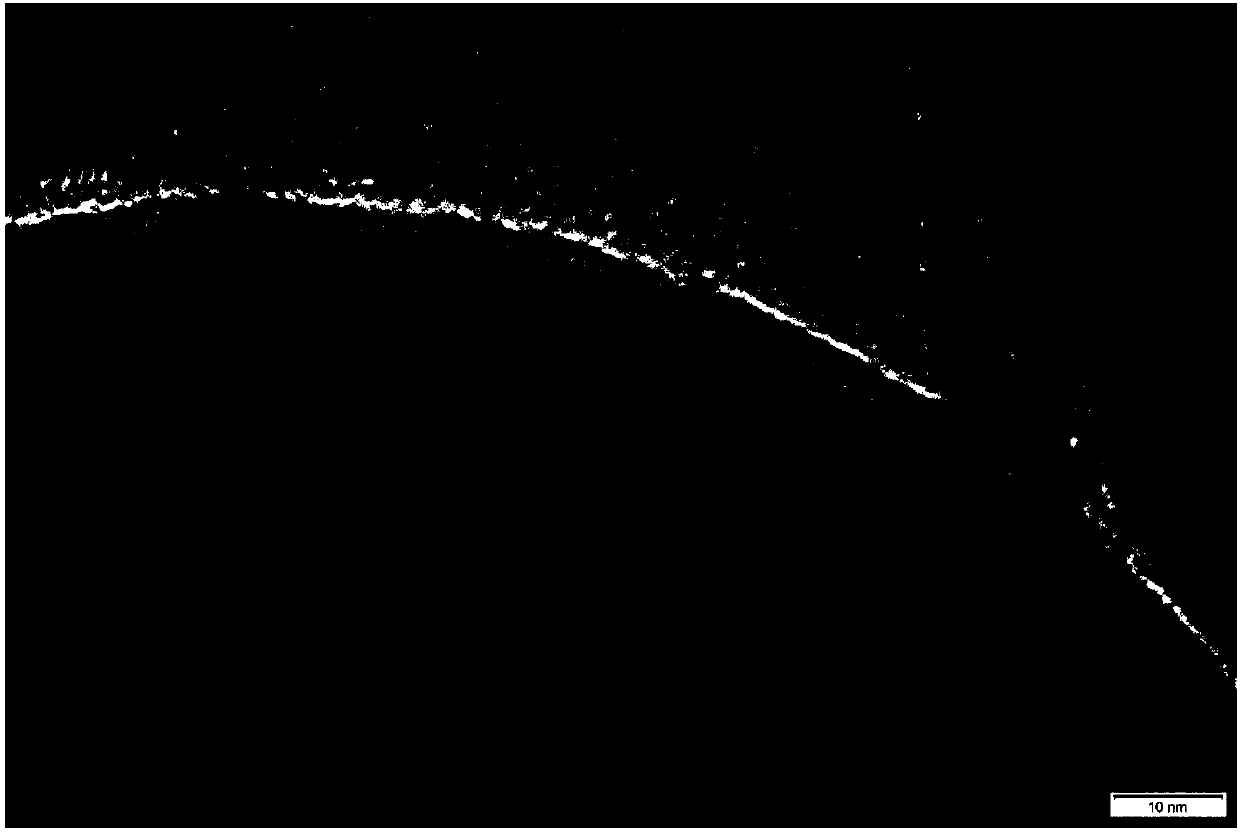

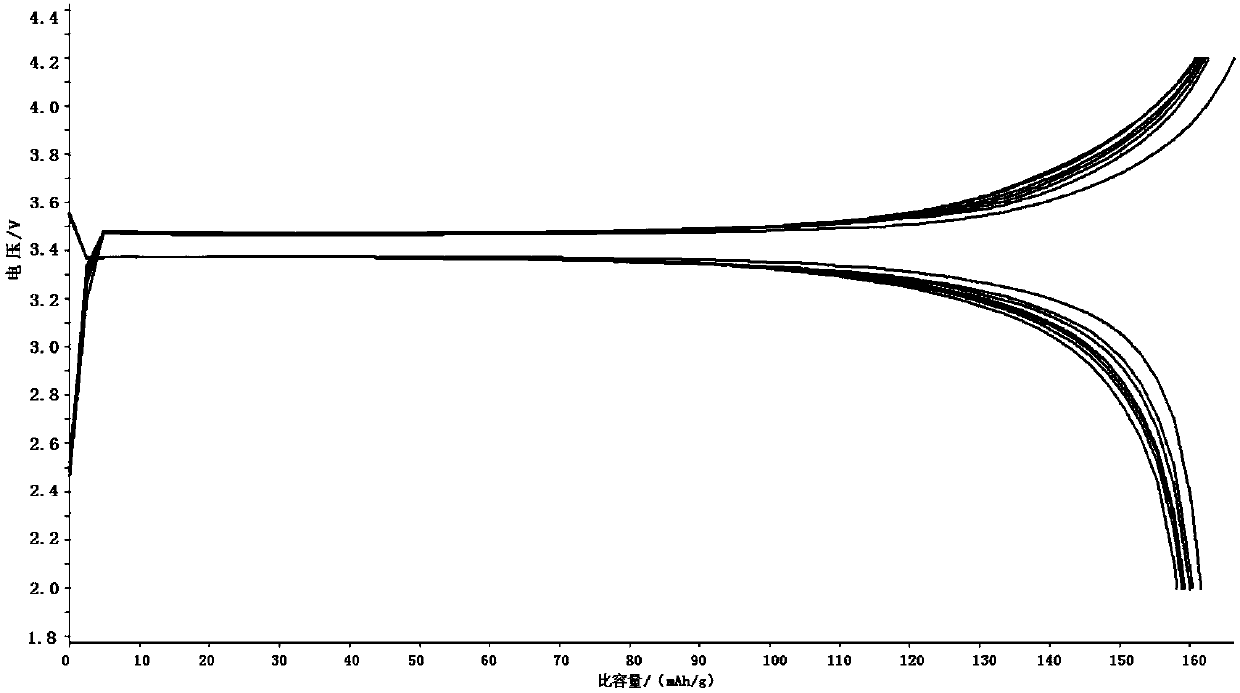

Image

Examples

Embodiment 1

[0063] (1) Preparation of LiFePO by ferrous oxalate method 4

[0064] Ferrous oxalate, ammonium dihydrogen phosphate, and lithium carbonate are mixed in a mass ratio of 1:1:1, dried, put into a high-temperature furnace, and calcined in a nitrogen atmosphere to obtain lithium iron phosphate material.

[0065] (2) Cathode material LiFePO 4 processing method

[0066] Stir the mixed solution of cyclohexanone and methanol with a molar ratio of 1:1 at 30° C. for 0.5 h to obtain a carbon source solution;

[0067] The resulting carbon source solution was added with a zinc oxide catalyst at 450°C and reacted for 0.5 hours to obtain carbon source gas;

[0068] 1kg of the lithium iron phosphate material obtained in step (1) is placed in a high-temperature furnace with a volume of 20L, nitrogen gas is introduced, and then carbon source gas is introduced, and the quality of the carbon source gas accounts for 5% of the mass of the lithium iron phosphate material , at 700°C, decompose to...

Embodiment 2

[0074] (1) Preparation of LiFePO by carbothermal reduction method 4

[0075] Iron phosphate and lithium carbonate are mixed at a mass ratio of 1:1.03, dried, placed in a high-temperature furnace, and calcined in a nitrogen atmosphere to obtain lithium iron phosphate material.

[0076] (2) Cathode material LiFePO 4 processing method

[0077] Stir the mixed solution of calcium formate and ethanol with a molar ratio of 1:1 at 35°C for 0.75h to obtain a carbon source solution;

[0078] The obtained carbon source solution was added with a tin oxide catalyst at 480°C, and reacted for 1 hour to obtain carbon source gas;

[0079] 1 kg of the lithium iron phosphate material obtained in step (1) is placed in a high-temperature furnace with a volume of 20 L, nitrogen gas is introduced, and then carbon source gas is introduced, and the quality of the carbon source gas accounts for 8% of the mass of the lithium iron phosphate material , at 800°C, pyrolyze to obtain unsaturated carbon s...

Embodiment 3

[0085] (1) Preparation of LiFePO by ferrous oxalate method 4 / C

[0086] Ferrous oxalate, ammonium dihydrogen phosphate, lithium carbonate, and carbon source are mixed and dried in a mass ratio of 1:1:1:1, put into a high-temperature furnace, and calcined in a nitrogen atmosphere to obtain carbon-coated phosphorous acid lithium iron material.

[0087] (2) Cathode material LiFePO 4 processing method

[0088] Stir the mixed solution of benzoquinone and toluene with a molar ratio of 1:1 at 65°C for 1 hour to obtain a carbon source solution;

[0089] Add the obtained carbon source solution at 550°C to a tin dioxide catalyst and react for 1 hour to obtain carbon source gas;

[0090] 1.2 kg of the carbon-coated lithium iron phosphate material obtained in step (1) is placed in a high-temperature furnace with a volume of 20 L, and nitrogen gas is introduced, and then carbon source gas is introduced. 6% of the mass of ferrous lithium material is cracked at 700°C to obtain unsatura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com