thermosetting coating composition

A composition and thermosetting technology, applied in polyurea/polyurethane coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture Embodiment 1

[0192] Manufacturing example 1 (acrylic resin)

[0193] Into a four-necked flask equipped with a stirrer, a thermometer, a cooling tube, and a nitrogen inlet, 31 parts of propylene glycol monomethyl ether was charged, and the temperature therein was raised to 110° C. while introducing nitrogen. After the temperature reached 110°C, the introduction of nitrogen was stopped, and 2 parts of 2-hydroxyethyl acrylate, 30 parts of methyl methacrylate, 22 parts of 2-ethylhexyl acrylate, 25 parts of styrene, A mixture of 1 part acrylic acid and 4 parts 2,2'-azobis(isobutyronitrile). Then, the mixture was aged at 110° C. for 2 hours while introducing nitrogen, and then cooled to 100° C. and diluted with propylene glycol monomethyl ether, thereby obtaining an acrylic resin (A-1) solution having a solid content of 60%. .

[0194] Acrylic resin (A-1) had a weight average molecular weight of 15,000 and a hydroxyl value of 106 mg KOH / g.

manufacture Embodiment 2

[0195] Manufacturing example 2 (epoxy resin)

[0196] In a flask equipped with a stirrer, a thermometer, a nitrogen inlet tube and a reflux condenser, 950 parts of jER1001 (trade name, produced by Mitsubishi Chemical Corporation, epoxy resin, epoxy equivalent 475, number average molecular weight 900), 236 parts of 1 , 6-hexanediol and 0.2 g of dimethylbenzylamine, and the mixture was reacted with each other at 200° C. until the epoxy equivalent became 30,000 or more, and ethylene glycol monobutyl ether was further added to the flask, An epoxy resin (A-2) having a solid content of 60% was thus obtained. The number average molecular weight of the epoxy resin (A-2) was 2,500.

[0197] Production of blocked polyisocyanate curing agent (B)

manufacture Embodiment 3

[0199] Into a four-necked flask equipped with a stirrer, a heating device, a cooling device and a decompression device, 272 parts of hexamethylene diisocyanate and 214 parts of methyl ethyl ketone were added, followed by heating to 60°C. Then 169 parts of methyl ethyl ketone oxime were gradually added to the four-necked flask over 1 hour while stirring. Thereafter, the mixture was allowed to react at 60°C for 2 hours, and then 59 parts of trimethylolpropane was gradually added thereto so that the temperature did not reach 70°C or more. With stirring, the reaction mixture was allowed to react at 60° C. until no free isocyanate groups were detected by infrared spectroscopy. After the reaction was completed, a blocked polyisocyanate curing agent (B-1) having a solid content of 70% was obtained. The NCO amount of the obtained blocked polyisocyanate curing agent (B-1) was 16.4%.

[0200] Production of amine compound (C)

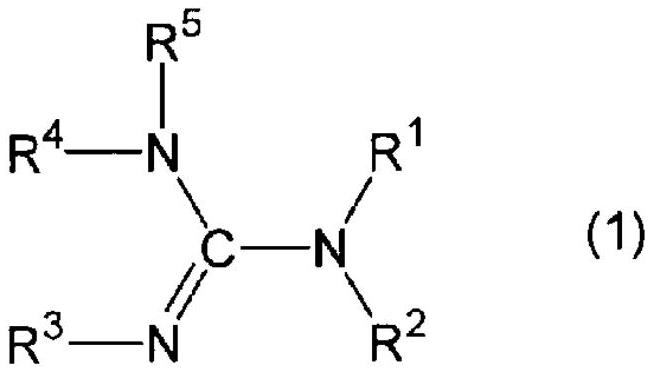

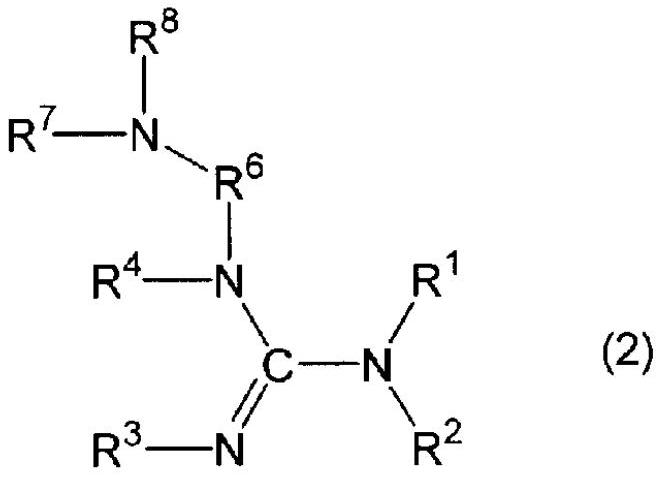

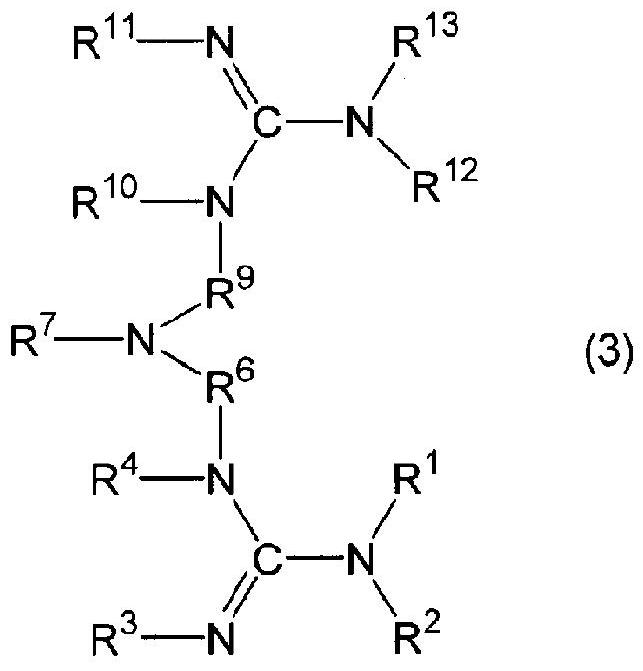

[0201] Among the amine compounds (C-1) to (C-16) shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com