A method for improving calcification of artificial biological valve by means of coating

A biological valve and artificial technology, applied in the direction of heart valves, can solve problems affecting the normal biological function and service life of valves, loss of soluble protein, calcification and hardening of valve leaflets, etc., to eliminate potential risks, enhance stability, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation of amino silicone oil emulsion can be carried out as follows:

[0049] Take a certain amount of deionized water and add it to a 250ml three-necked flask, add non-ionic emulsifier alkylphenol polyoxyethylene ether TX-10 and fatty alcohol polyoxyethylene ether AEO, according to the compounding ratio 1 / 2 to 2 / 3 drops Add, stir and mix evenly, then add an appropriate amount of co-emulsifier, continue to emulsify until clarification, slowly drop in the commercially available amino silicone oil raw material equivalent to 2 times the dosage of the compound emulsifier, and fully emulsify it under high-speed stirring After stirring for 2 hours, add a certain amount of acetic acid, slowly heat up to 30 degrees and mix evenly, slowly add a certain amount of water until the viscosity of the emulsion decreases, adjust the pH value to 6-7, and continue to stir for 60 minutes to obtain half Transparent microemulsion. The ammonia value range of the obtained amino silic...

Embodiment 1

[0056] The present embodiment provides the method for improving the calcification of prosthetic valve by means of coating, and this method comprises the following steps:

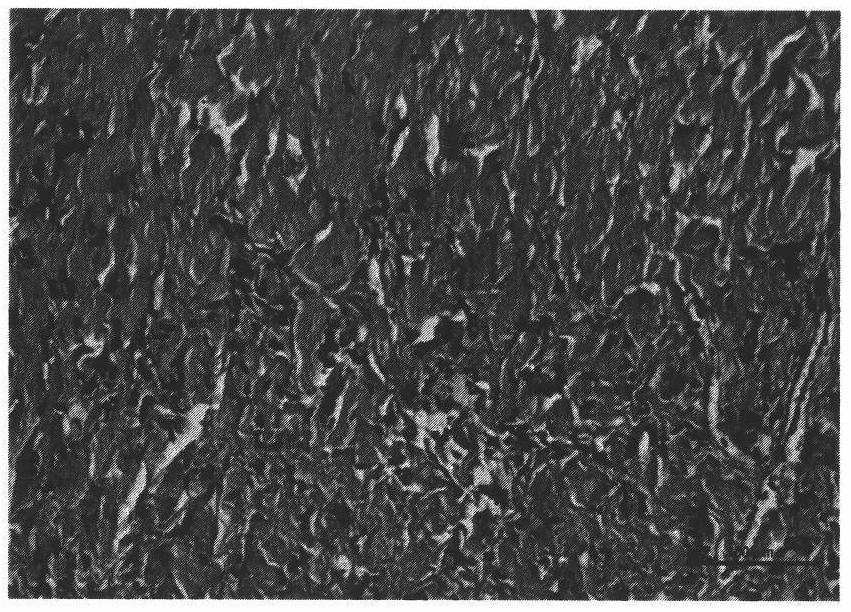

[0057] Step 1: Obtain fresh bovine pericardium material from the cattle farm;

[0058] Step 2: Pretreat the bovine pericardium material to remove the residual fat on the surface;

[0059] Step 3: Wash the bovine pericardium material in Hank's solution for 6 hours at a temperature of 8 degrees;

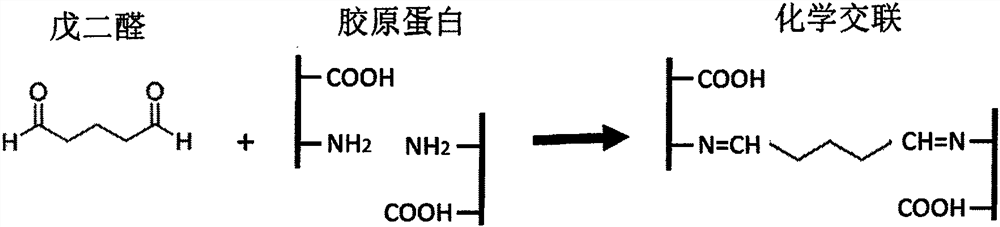

[0060] Step 4: Soak the cleaned pericardial material in 1% glutaraldehyde solution and react for 24 hours;

[0061] Step 5: washing the reacted pericardial material with saline;

[0062] Step 6: Soak the cleaned pericardial material in an amino silicone oil emulsion with an ammonia value of 0.3mmol / g and a viscosity of 1000mpa.s; soak for 3 hours at room temperature;

[0063] Step 7: Wash the pericardium after the above treatment with normal saline for 4 hours at a temperature of 5 degrees;

[0064] Step 8: use t...

Embodiment 2

[0074] A method for improving calcification of an artificial biological valve by means of a coating according to the present invention comprises the following steps:

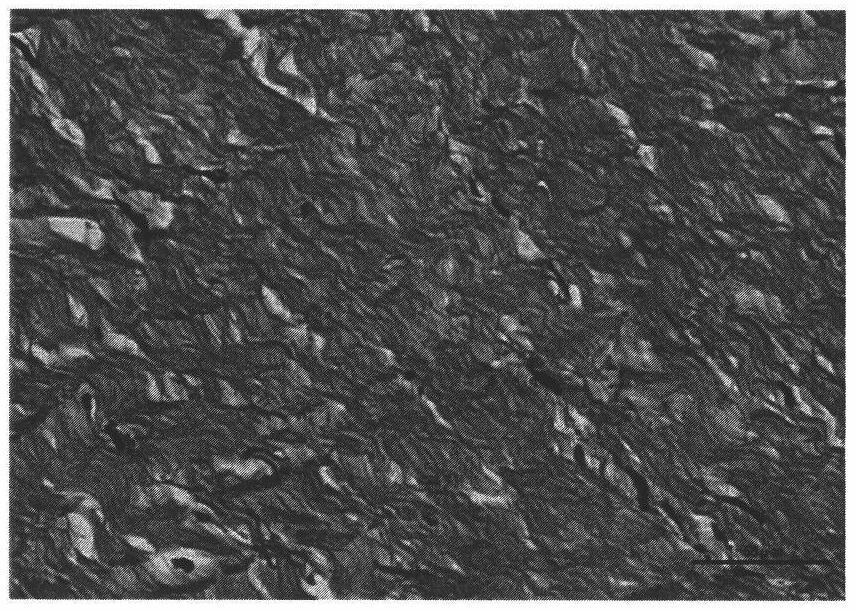

[0075] Step 1: Obtain fresh pig heart bag;

[0076] Step 2: Pretreat the pig pericardium to remove excess fat and blood vessels on the surface;

[0077] Step 3: Wash the finished pig pericardium with physiological saline at a temperature of 4 degrees for 4 hours;

[0078] Step 4: Soak the pig pericardium in a 0.5% glyoxal solution for 48 hours and at a temperature of 8 degrees;

[0079] Step 5: Wash the fixed porcine pericardium with Hank's solution for 0.5 hour, at room temperature;

[0080] Step 6: Soak the pig pericardium in polysiloxane emulsion with an ammonia value of 0.2mmol / g, a viscosity of 2000mPa.s, soak for 3 days, and soak at a temperature of 37 degrees;

[0081] Step 7: The pig pericardium that has completed the above treatment is further washed with physiological saline for 1 hour and at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com