Preparation method and application of carbon nanometer cage material with high nitrogen doping amount

A carbon nano-cage and doping amount technology, which is applied in nano-carbon, nano-technology, hybrid capacitor electrodes, etc., can solve problems such as differences in the preparation methods of nitrogen-doped carbon materials, and achieve excellent capacitance characteristics, uniform size and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

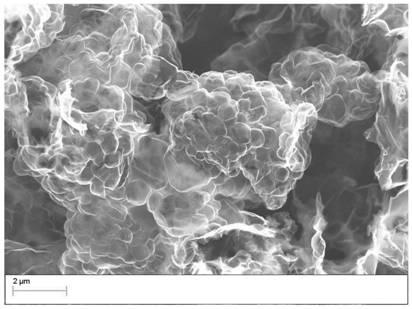

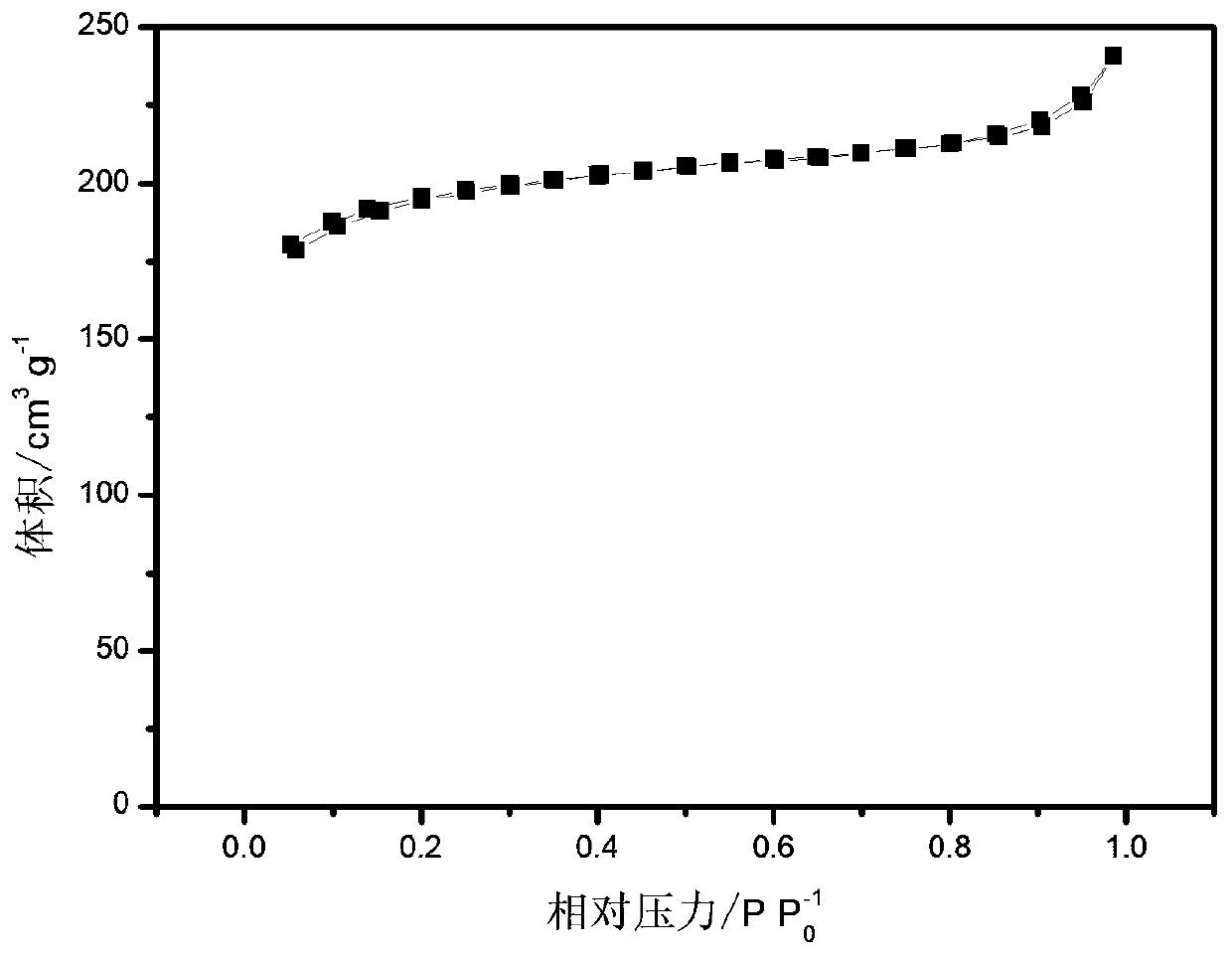

[0030] Weigh 3g of sucrose, 18g of potassium chloride, and 3g of dicyandiamide into a polytetrafluoro ball mill jar, then weigh 100g of agate balls into the ball mill jar, and mill for 2 hours. Put the ball-milled solid powder in a quartz boat, and then put it into a tube furnace equipped with a quartz tube; feed nitrogen inert gas, and the flow rate of the inert gas in the tube furnace is 50mL min -1 , then at 5°C min -1 Raise the temperature to 800°C at the heating rate, and the high-temperature carbonization holding time is 2 hours to obtain the initial product. The obtained primary product was soaked in hot water for 8 hours, then suction filtered, and dried in an oven at 80° C. for 24 hours to obtain a nitrogen-doped carbon nanocage material with a nitrogen content of 11.3 at%.

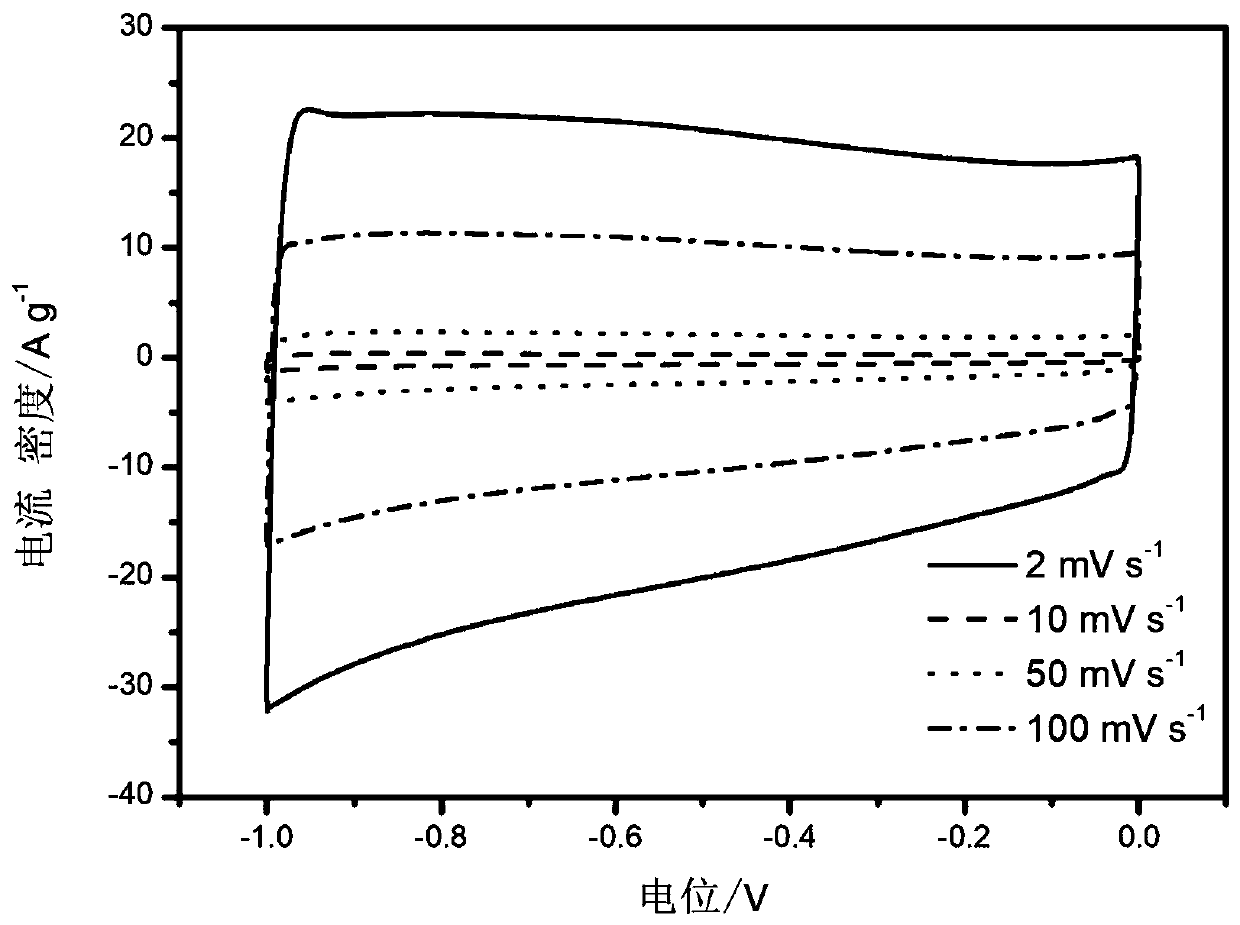

[0031] The carbon nanocage material prepared in this embodiment is prepared into an electrode sheet after being mixed in the ratio of active material: conductive agent (graphite): binder (polyte...

Embodiment 2

[0033] Weigh 3g of sucrose, 0.3g of potassium chloride, and 0.3g of dicyandiamide into a polytetrafluoro ball mill jar, then weigh 3.6g of agate balls into the ball mill jar, and mill for 0.1h. Put the ball-milled solid powder in a quartz boat, and then put it into a tube furnace equipped with a quartz tube; feed nitrogen inert gas, and the flow rate of the inert gas in the tube furnace is 20mLmin -1 , then at 1°C min -1 Raise the temperature to 1000°C at a certain heating rate, and the high-temperature carbonization holding time is 0.01h to obtain the primary product. The obtained primary product was soaked in hot water at 10° C. for 24 hours, then suction-filtered, and dried in an oven at 80° C. for 24 hours to obtain a nitrogen-doped carbon nanocage material with a nitrogen content of 10.9 at%.

Embodiment 3

[0035] Weigh 3g of sucrose, 100g of potassium chloride, and 30g of dicyandiamide into a polytetrafluoro ball mill jar, then weigh 133g of agate balls into the ball mill jar, and mill for 12 hours. Put the ball-milled solid powder in a quartz boat, and then put it into a tube furnace equipped with a quartz tube; feed nitrogen inert gas, and the flow rate of the inert gas in the tube furnace is 100mLmin -1 , then at 20°C min -1 Raise the temperature to 500°C at a heating rate of 0.1 h to obtain the initial product. The obtained primary product was soaked in hot water at 100°C for 0.1h, then suction filtered, and dried in an oven at 80°C for 24h to obtain a nitrogen-doped carbon nanocage material with a nitrogen content of 11.2at%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap