Preparation method of coating agent

A technology of coating agent and preparation steps, which is applied in the field of preparation of coating agent, can solve the problems of unsatisfactory salt resistance and low coating effect, and improve the coating ability of thickening, temperature resistance, and film formation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

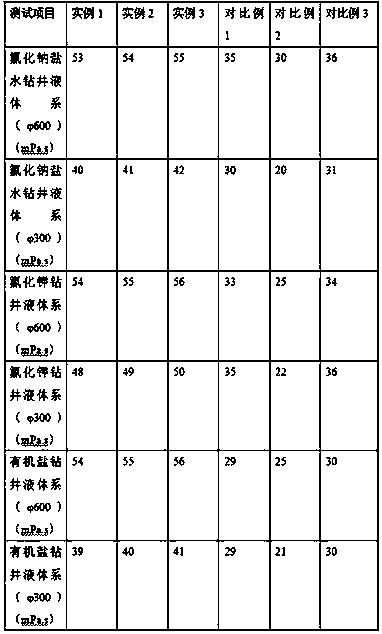

Examples

preparation example Construction

[0031] Preparation of mineral composites: mix kaolin, slag, and sodium silicate solution with a mass fraction of 40% according to a mass ratio of 2:2:3, put them into a reactor with a stirrer, and stir for 20 minutes to obtain minerals compound, spare;

[0032] Preparation of modified bamboo fiber:

[0033]The chloroacetic acid solution that is 30% by mass fraction, isopropanol is mixed to obtain mixed solution after being 2: 3 by mass ratio, and the sodium hydroxide solution that bamboo fiber, mixed solution, mass fraction are 10% is 3 by mass ratio: Mix 2:1 and put it into a beaker, and pass nitrogen into the beaker until all the air is replaced, under the protection of nitrogen, heat up to 30°C, stir for 30 minutes, and obtain modified bamboo fiber, which is ready for use;

[0034] Preparation of modified silicic acid gel:

[0035] Mix dilute hydrochloric acid and saturated sodium silicate solution with a mass fraction of 5% at a mass ratio of 1:2, put them in a stirrer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com