A near-infrared sulfide long-lasting luminescent material and its preparation method and application

A long afterglow luminescence, sulfide technology, applied in luminescent materials, chemical instruments and methods, pharmaceutical formulations, etc., can solve the problems of few luminescent centers, complex processes, unfavorable production, etc., and achieve easy large-scale technology promotion and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

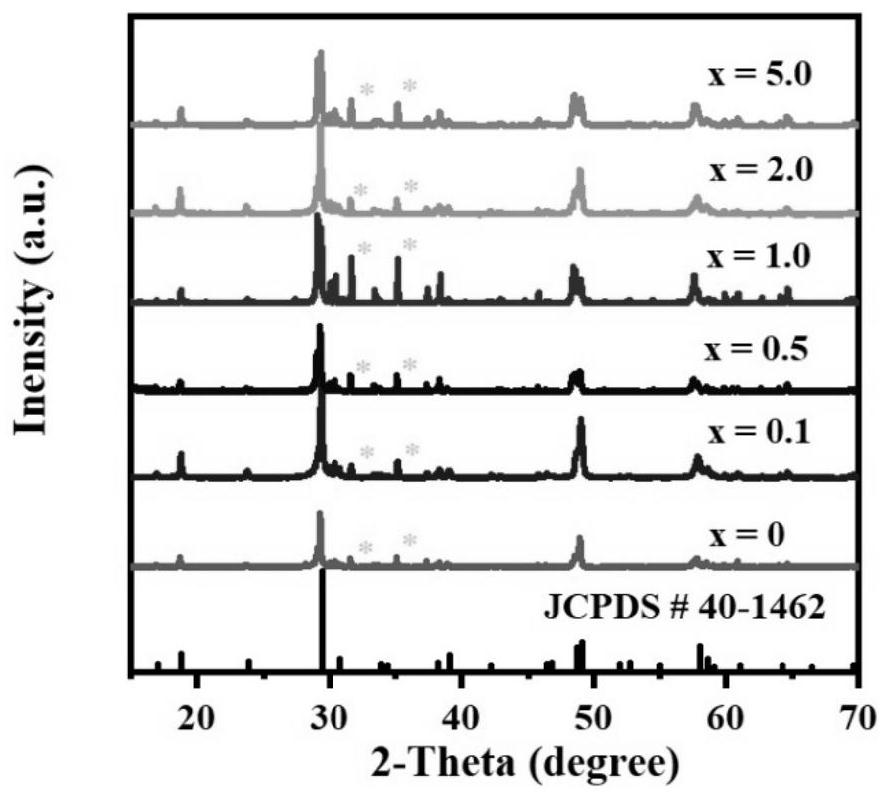

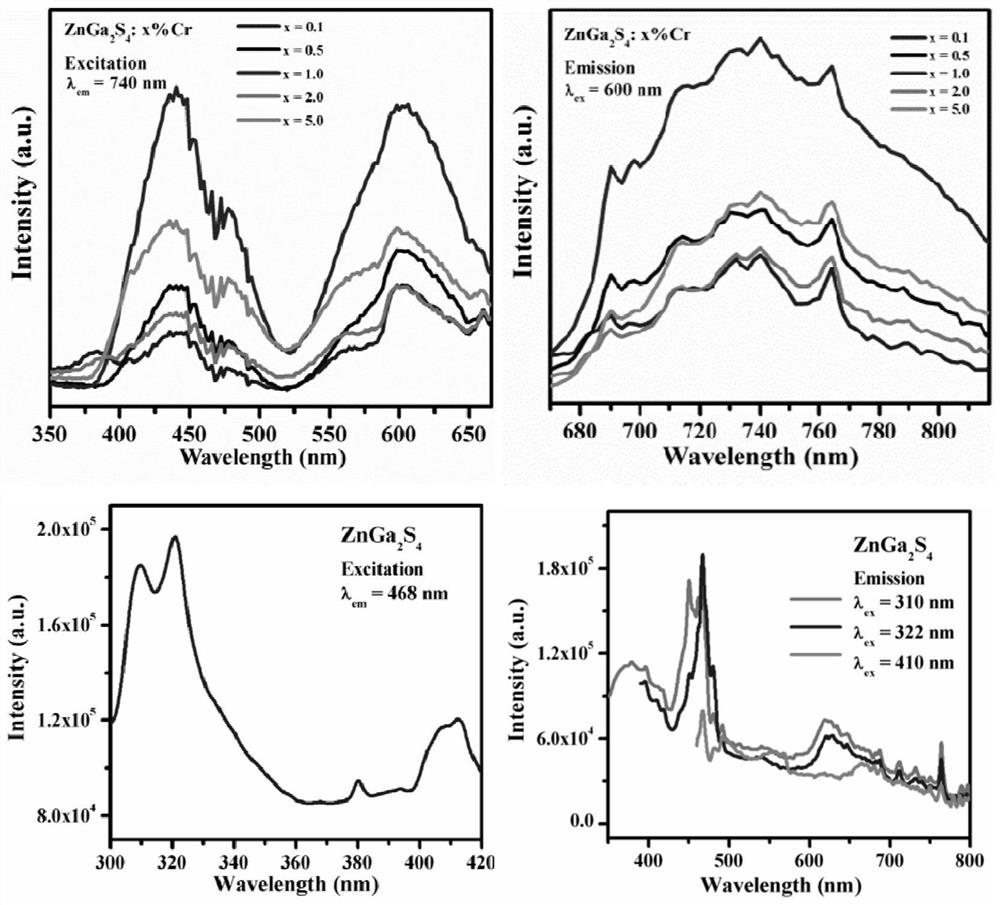

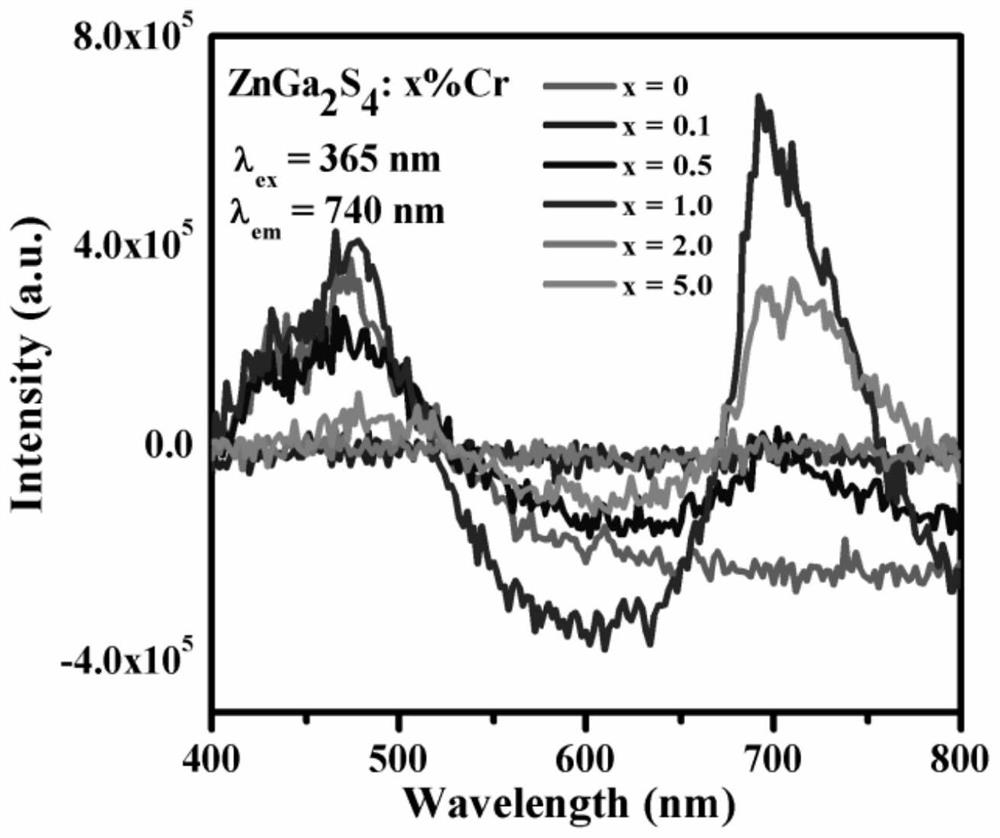

Embodiment 1

[0031] According to the following composition: Matrix is ZnGa 2 S 4 , Cr 3+ The doping amount is 0.1mol%; respectively weigh Ga 2 S 3 1.4133g, ZnS 0.5852g and Cr 2 O 3 0.0004g was heated to 1160°C at room temperature under a sulfur atmosphere (raw material: mass ratio of sublimated sulfur = 1:5) after grinding and mixing, and calcined for 3 hours. During the cooling process, when the pressure dropped to the equilibrium pressure, argon was introduced Always keep the furnace tube pressure at a slightly positive pressure state. The prepared near-infrared sulfide long afterglow luminescent material is ZnGa 2 S 4 : 0.1mol% Cr 3+ .

Embodiment 2

[0033] This embodiment is basically the same as the embodiment 1, the difference is that according to the following components: the matrix is ZnGa 2 S 4 , Cr 3+ The doping amount is 0.5mol%, respectively weighing Ga 2 S 3 1.4077g, ZnS 0.5852g and Cr 2 O 3 0.0023g, the prepared near-infrared sulfide long afterglow luminescent material is ZnGa 2 S 4 : 0.5mol% Cr 3+ .

Embodiment 3

[0035] This embodiment is basically the same as the embodiment 1, the difference is that according to the following components: the matrix is ZnGa 2 S 4 , Cr 3+ The doping amount is 1mol%, respectively weighing Ga 2 S 3 1.4006g, ZnS 0.5852g and Cr 2 O 3 0.0046g, the prepared near-infrared sulfide long afterglow luminescent material is ZnGa 2 S 4 : 1mol%Cr 3+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com