Low-grade lead-zinc oxidized ore resource utilization method

An oxidized ore, low-grade technology, used in the improvement of process efficiency, cement production and other directions, can solve problems such as long process flow, achieve high comprehensive recovery rate, reduce energy consumption, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

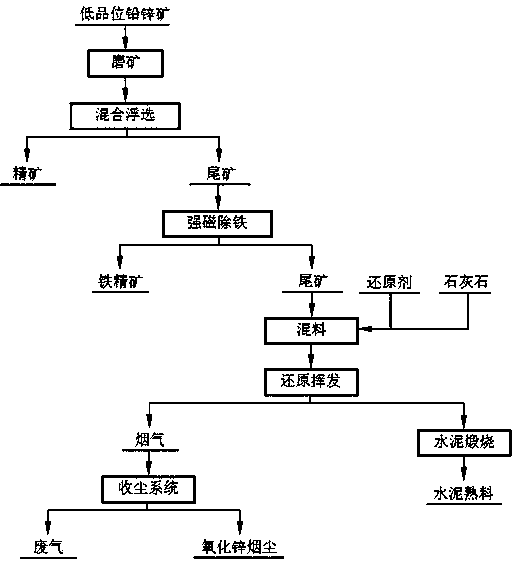

Image

Examples

Embodiment 1

[0022] A method for resource utilization of low-grade lead-zinc oxide ore, the specific steps are as follows:

[0023] 1) Mixed flotation of sandstone-type oxide ore, raw material composition: Pb 0.95%, Zn 6.28% (of which ZnS zinc content 2.63%, accounting for 41.88% of the total zinc), Fe 5.73%, SiO 2 44.18%; Al 2 O 3 2.01%, CaO 5.45%, MgO 0.29%; ZnS zinc content in tailings after beneficiation is 0.48%, ZnS beneficiation recovery rate is 81.7%, flotation lead-zinc sulfide concentrate Pb+Zn is 55.1%;

[0024] 2) The raw material contains less than 5.73% iron. The mixed flotation tailings are subjected to ferromagnetic separation. After magnetic separation, the iron content of the tailings is 3.58%, and the iron content of the iron concentrate produced by the magnetic separation is 62.1%, which is sold as iron concentrate;

[0025] 3) Magnetic separation tailings, anthracite, limestone, and shale are uniformly mixed and granulated in a weight ratio of 1:0.2:1.8:0.4. The mixture is fed...

Embodiment 2

[0028] A method for resource utilization of low-grade lead-zinc oxide ore, the specific steps are as follows:

[0029] 1) Limestone-type oxide ore is mixed flotation. The raw material composition is: Pb 1.02%, Zn 7.83% (including ZnS zinc content 1.56%, accounting for 19.92% of the total zinc), Fe 12.35%, SiO 2 25.66%; Al 2 O 3 1.78%, CaO 15.79%, MgO 0.3%; ZnS zinc content in tailings after beneficiation is 0.41%, ZnS beneficiation recovery rate is 73.7%, and Pb+Zn content in lead-zinc concentrate is 51.9%;

[0030] 2) The raw material contains 12.35% iron, the mixed flotation tailings are subjected to ferromagnetic separation, the iron content of the ferromagnetic separation tailings is 3.8%, and the iron content of the iron concentrate is 62%, which is sold as iron concentrate;

[0031] 3) Magnetic separation tailings, anthracite, limestone, and shale are mixed uniformly and granulated at a weight ratio of 1:0.1:0.8:0.2. The mixture is fed to the rotary kiln at a speed of 50t / h, an...

Embodiment 3

[0034] A method for resource utilization of low-grade lead-zinc oxide ore, the specific steps are as follows:

[0035] 1) Mix sandstone-type oxide ore and limestone-type oxide ore at a ratio of 1:1. The composition of the mixture is 0.93%, Zn 6.85% (of which ZnS zinc content is 1.88%, accounting for 27.44% of total zinc), Fe 8.52 %, SiO 2 32.63%; Al 2 O 3 2.21%, CaO12.41%, MgO 0.4%; ZnS zinc content in tailings after beneficiation is 0.31%, ZnS beneficiation recovery rate is 83.5%, and Pb+Zn content in lead-zinc sulfide concentrate is 53.6%;

[0036] 2) The raw material contains 8.52% iron, the mixed flotation tailings are subjected to ferromagnetic separation, the iron content of the ferromagnetic separation tailings is 3.2%, and the iron content of the iron concentrate is 65.4%, which is sold as iron concentrate;

[0037] 3) Magnetic separation tailings, anthracite, limestone, and shale are mixed uniformly and granulated at a weight ratio of 1:0.15:1.1:0.2. The mixture is fed to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com