Production method of ultra-high molecular weight polyethylene

An ultra-high molecular weight, polyethylene technology, applied in the field of ultra-high molecular weight polyethylene production, can solve the problems of difficult to break, unable to obtain spherical small particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

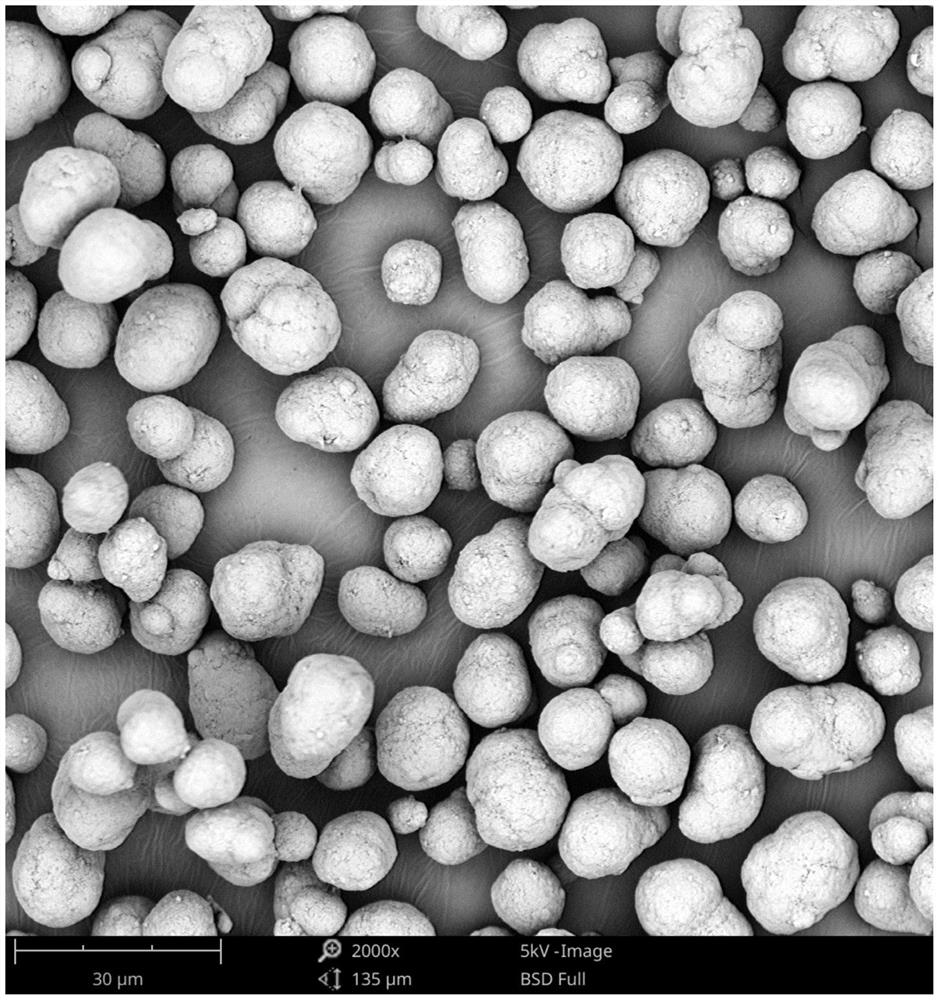

Image

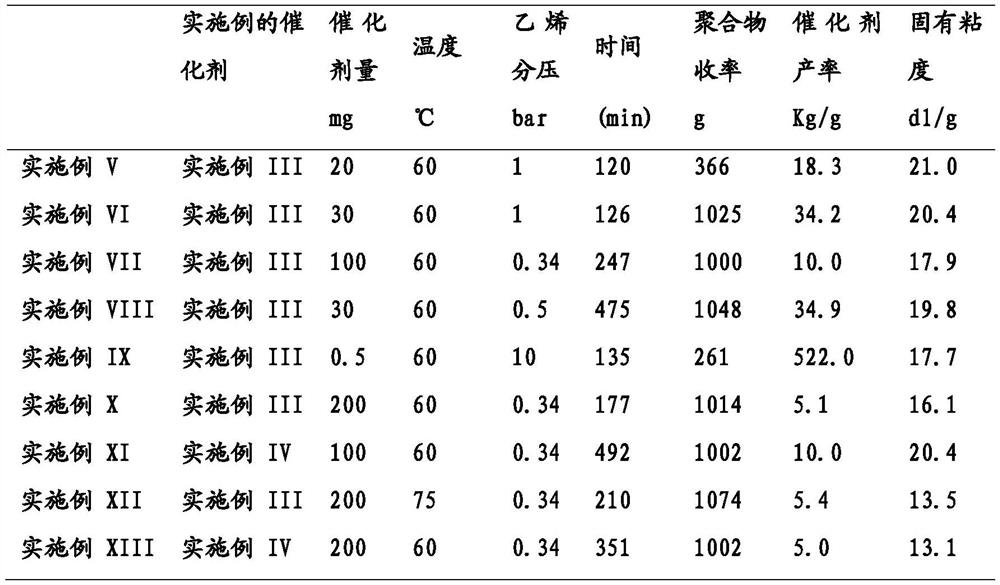

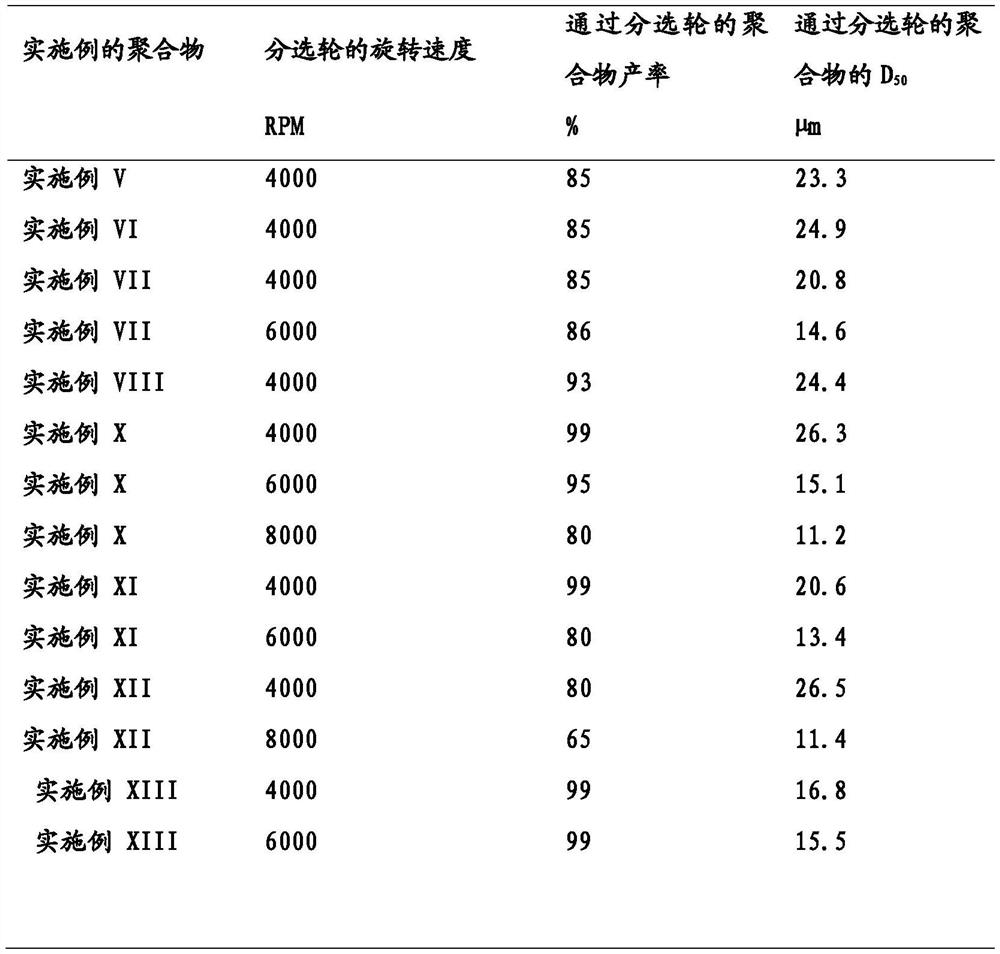

Examples

Embodiment I

[0087] Contains Mg(OC 2 h 5 ) 2 and Ti(OC 4 h 9 ) 4 Preparation of the hydrocarbon solution

[0088] 92 g of granulated Mg(OC 2 h 5 ) 2 and 138 ml Ti(OC 4 h 9 ) 4 Add to a 2 L round bottom flask equipped with a reflux condenser and stirrer. With gentle stirring, the mixture was heated to 180°C and then stirred for 1.5 hours. During this time, a clear liquid was obtained. The mixture was cooled to 120°C, then diluted with 518 ml of hexane. The mixture was further cooled to 67°C as the hexanes were added. The mixture was kept at this temperature for 2 hours, then cooled to room temperature. The resulting clear solution was stored under nitrogen atmosphere and used as obtained. Analysis of the solution showed a titanium concentration of 0.55 mol / l.

Embodiment II

[0090] Contains Mg(OC 2 h 5 ) 2 and Ti(OC 8 h 17 ) 4 Preparation of the hydrocarbon solution

[0091] 112 g of granular Mg(OC 2 h 5 ) 2 and 200 ml Ti(OC 8 h 17 ) 4 Add to a 2 L round bottom flask equipped with a reflux condenser and stirrer. With gentle stirring, the mixture was heated to 180°C, followed by stirring for 2 hours. During this time, a clear liquid was obtained. The mixture was cooled to 120°C, then diluted with 1186 grams of hexane. The mixture was further cooled to 67°C as the hexanes were added. The mixture was kept at this temperature for 2 hours, then cooled to room temperature. The resulting clear solution was stored under nitrogen atmosphere and used as obtained. Analysis of the solution showed a titanium concentration of 0.34 mol / l.

Embodiment III

[0093] Catalyst preparation

[0094] In a 0.8 liter glass reactor equipped with baffles, reflux condenser and stirrer, 180 ml of hexane and 136 ml of the compound of example I (80 mmol Ti) were charged. Set the stirrer to 1400 RPM. Via a peristaltic pump, 250 ml of diisobutylaluminum chloride (DiBAC) solution (150 ml of DiBAC + 100 ml of hexane) was added over a period of 2 hours. The molar ratio of aluminum to titanium was 10.7. The mixture was then refluxed for 2 hours. After cooling to ambient temperature, the red / brown suspension obtained was washed 5 times with 500 ml of hexane by decantation. Finally, the solid was placed in 500 ml of hexane and the resulting slurry was stored under nitrogen atmosphere. The average particle size of the catalyst is 0.18 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com