Sea cucumber and spirulina mixed powder and preparation method thereof

A technology of spirulina powder and spirulina, which is applied in the functions of food ingredients, food forming, food science and other directions, can solve problems such as the difficulty of ultrafine grinding of sea cucumbers, and achieves the improvement of product yield, health care and nutritional functions, and efficiency. The effect of preventing rapid settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The sea cucumber spirulina mixed powder is composed of 5 parts of superfine sea cucumber powder and 15 parts of spirulina powder. The particle diameter of the superfine sea cucumber powder is 120 mesh, and the particle diameter of the spirulina powder is 150 mesh.

[0038] The preparation method of the above-mentioned sea cucumber spirulina mixed powder is as follows:

[0039] ⑴ Sea cucumber cleaning: Remove the viscera of fresh sea cucumbers and wash them. The temperature of the cleaning water is 10°C;

[0040] (2) Vacuum tumbling of sea cucumbers: Vacuum tumbling of the decontaminated and cleaned sea cucumbers obtained in step (1) is realized by a vacuum tumbling machine. The working conditions are: vacuum degree 0.04MPa, rotating speed 12r / min, tumbling time 1h, Kneading temperature 4°C;

[0041] (3) Vacuum freeze-drying of sea cucumbers: Vacuum freeze-dry the vacuum-tumbled sea cucumbers obtained in step (2), and the working conditions are: freeze at -18°C for 16 h...

Embodiment 2

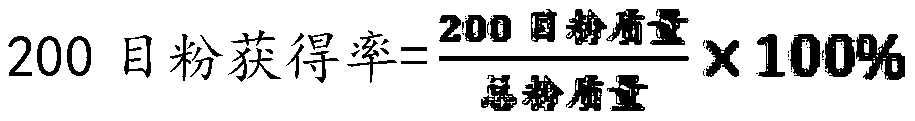

[0045] Sea cucumber spirulina mixed powder is composed of 10 parts of superfine sea cucumber powder, 8 parts of spirulina powder, 20 parts of soybean powder, 20 parts of sesame powder, and 40 parts of millet flour. The particle size of sea cucumber superfine powder is 150 mesh. The spirulina The particle size of the powder is 200 mesh.

[0046] The preparation method of the above-mentioned sea cucumber spirulina mixed powder is as follows:

[0047] ⑴ Sea cucumber cleaning: Remove the internal organs of fresh sea cucumbers and wash them. The temperature of the cleaning water is 5°C;

[0048] (2) Vacuum tumbling of sea cucumbers: Vacuum tumbling of the decontaminated and cleaned sea cucumbers obtained in step (1) is realized by a vacuum tumbling machine. The working conditions are: vacuum degree 0.08MPa, rotating speed 3r / min, tumbling time 4h, Kneading temperature 10°C;

[0049](3) Vacuum freeze-drying of sea cucumbers: Vacuum freeze-dry the vacuum-tumbled sea cucumbers obtai...

Embodiment 3

[0053] Sea cucumber spirulina mixed powder consists of 8 parts of superfine sea cucumber powder, 12 parts of spirulina powder, 10 parts of soybean powder, 10 parts of sesame powder, 25 parts of millet flour, and 2 parts of chia seed powder. The particle size of sea cucumber superfine powder is 200 mesh , the particle size of the spirulina powder is 200 mesh.

[0054] The preparation method of the above-mentioned sea cucumber spirulina mixed powder is as follows:

[0055] ⑴ Sea cucumber cleaning: Remove the internal organs of fresh sea cucumbers and wash them. The temperature of the cleaning water is 5°C;

[0056] (2) Vacuum tumbling of sea cucumbers: Vacuum tumbling of the cleaned sea cucumbers obtained in step (1) is realized by a vacuum tumbling machine. The working conditions are: vacuum degree 0.06MPa, rotating speed 9r / min, tumbling time 3h, Kneading temperature 4°C;

[0057] (3) Vacuum freeze-drying of sea cucumbers: Vacuum freeze-dry the vacuum-tumbled sea cucumbers o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com