Preparation method of fixing anthraquinone compound on surface of inorganic filler, and application thereof

A technology of inorganic fillers and compounds, which is applied in the field of preparation of anthraquinone compounds fixed on the surface of inorganic fillers, can solve the problems of low final yield, long time consumption, long reaction steps, etc., and achieves simple reaction process, improved operability, and reaction The effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

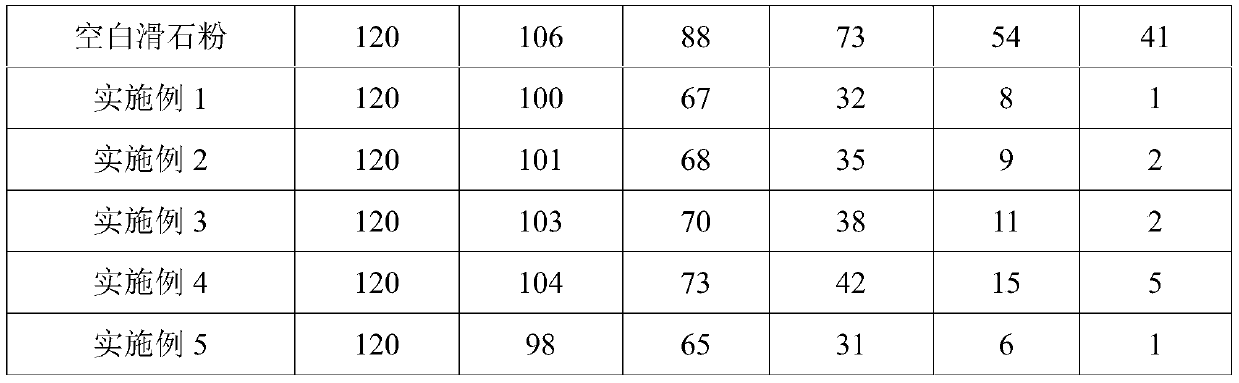

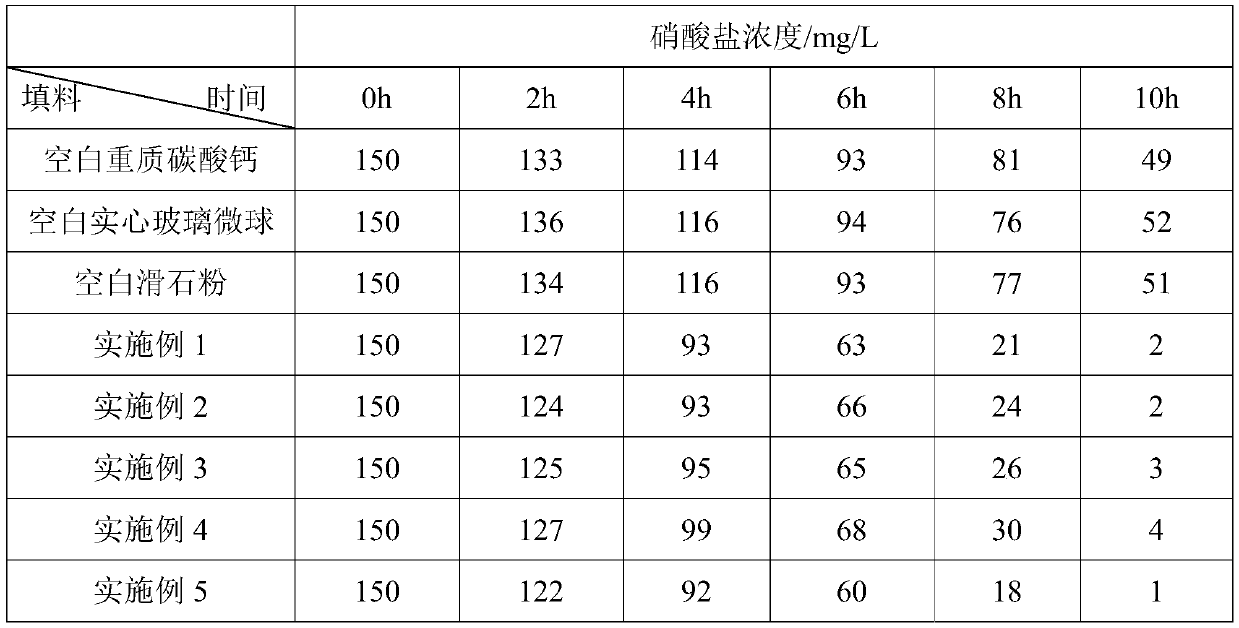

[0035] 50 parts of absolute ethanol, 6 parts of chloropropyl triethoxysilane and 0.5 parts of dilute hydrochloric acid with a mass concentration of 0.05 wt% were stirred at room temperature for 0.5 hours, added to 100 parts of 800 mesh heavy calcium carbonate, and heated to 60 ℃, stirred and reacted for 2 hours, lowered the temperature, filtered, and the filtered solid was washed 3 times with absolute ethanol and dried to obtain chloropropyl modified heavy calcium carbonate.

[0036] Place the container in a water bath at 12°C, add 100 parts of chloropropyl-modified heavy calcium carbonate, 22 parts of 2-aminoanthraquinone, 400 parts of tetrahydrofuran and 11 parts of triethylamine in sequence, stir for 5 hours and heat up to 55°C , stirred for 3 hours, filtered, and the filtered solid was washed 3 times with deionized water, then washed 3 times with absolute ethanol, and dried to obtain heavy calcium carbonate with an anthraquinone compound fixed on the surface. FT-IR analysi...

Embodiment 2

[0038] 100 parts of absolute ethanol, 10 parts of chloropropyltrimethoxysilane and 0.5 parts of dilute hydrochloric acid with a mass concentration of 0.1 wt% were stirred at room temperature for 0.5 hours, added to 100 parts of solid glass microspheres with an average particle diameter of 30 μm, and heated to 45°C, stirred and reacted for 4 hours, cooled down, filtered, and the filtered solid was washed three times with absolute ethanol and dried to obtain solid glass microspheres 1 modified with chloropropyl groups.

[0039]Place the container in a water bath at 15°C, add 100 parts of chloropropyl-modified solid glass microspheres 1, 30 parts of 1-aminoanthraquinone, 400 parts of toluene and 18 parts of triethylamine in sequence, stir for 7 hours, and heat up to 60 ℃, stirred for 2 hours, filtered, the filtered solid was washed 3 times with deionized water, and then washed 3 times with absolute ethanol, and dried to obtain solid glass microspheres 1 with anthraquinone compound...

Embodiment 3

[0041] Place the container in a water bath at 13°C, add 100 parts of chloropropyl-modified solid glass microspheres 1 obtained in Example 2, 30 parts of 1,5-diaminoanthraquinone, 500 parts of toluene and 30 parts of triethylamine , stirred and reacted for 7 hours, heated to 60°C, stirred for 2 hours, filtered, and the filtered solid was washed 3 times with deionized water, then washed 3 times with absolute ethanol, and dried to obtain a solid glass microstructure with an anthraquinone compound fixed on the surface. ball 2. The elemental analysis method was used to measure the N element content of the solid glass microspheres before and after immobilization, and the content of anthraquinone compounds immobilized on the surface of the solid glass microspheres was calculated to be 1.22 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com