Diatomite-based porous ceramic as well as preparation method and system thereof

A technology of diatomite and porous ceramics, which is applied in the field of porous ceramics, can solve the problems of low strength of porous ceramics, unfavorable industrial application, complex process, etc., and achieve the advantages of improving mixing efficiency and mixing effect, improving efficiency, and uniform pore distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

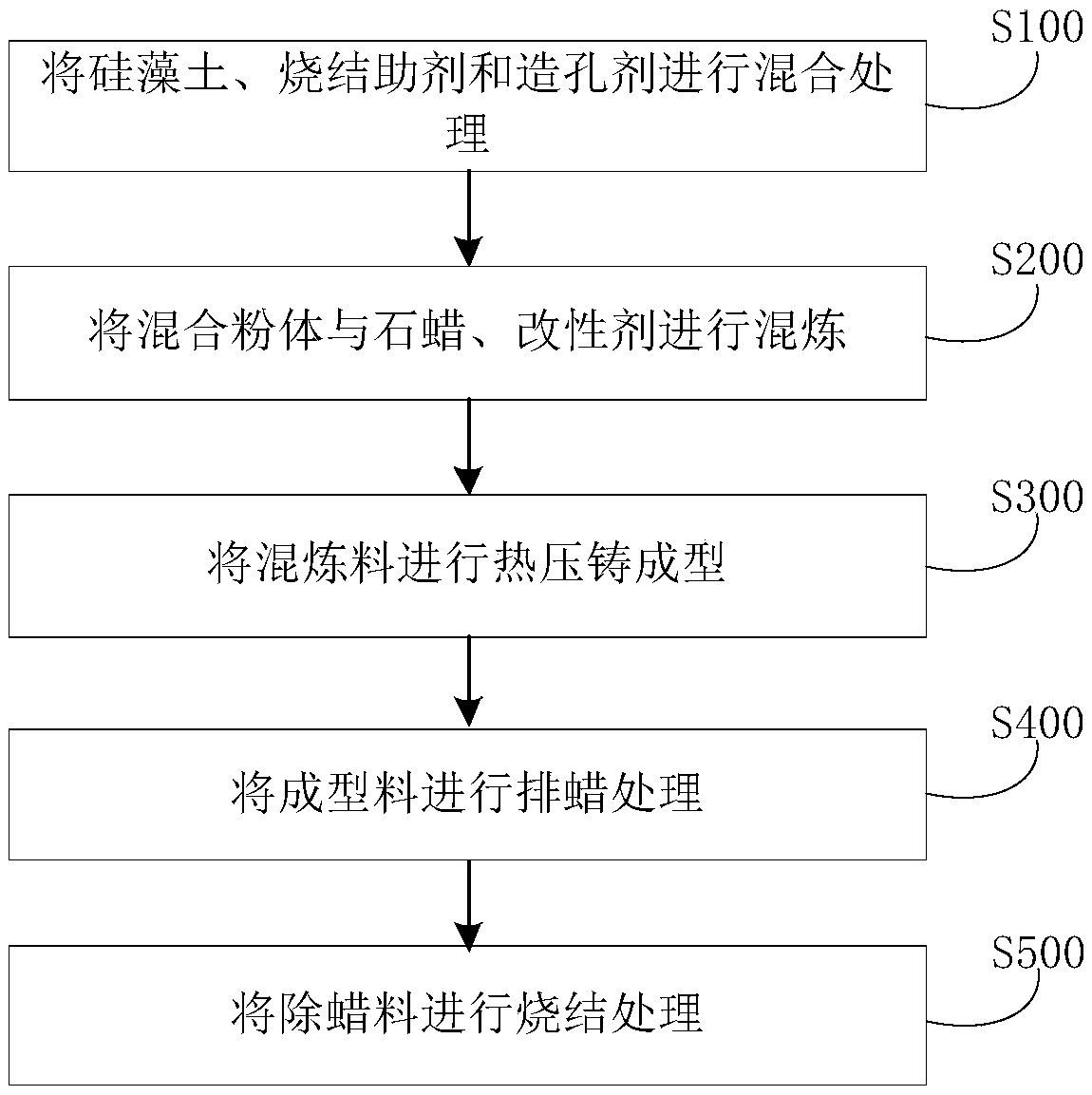

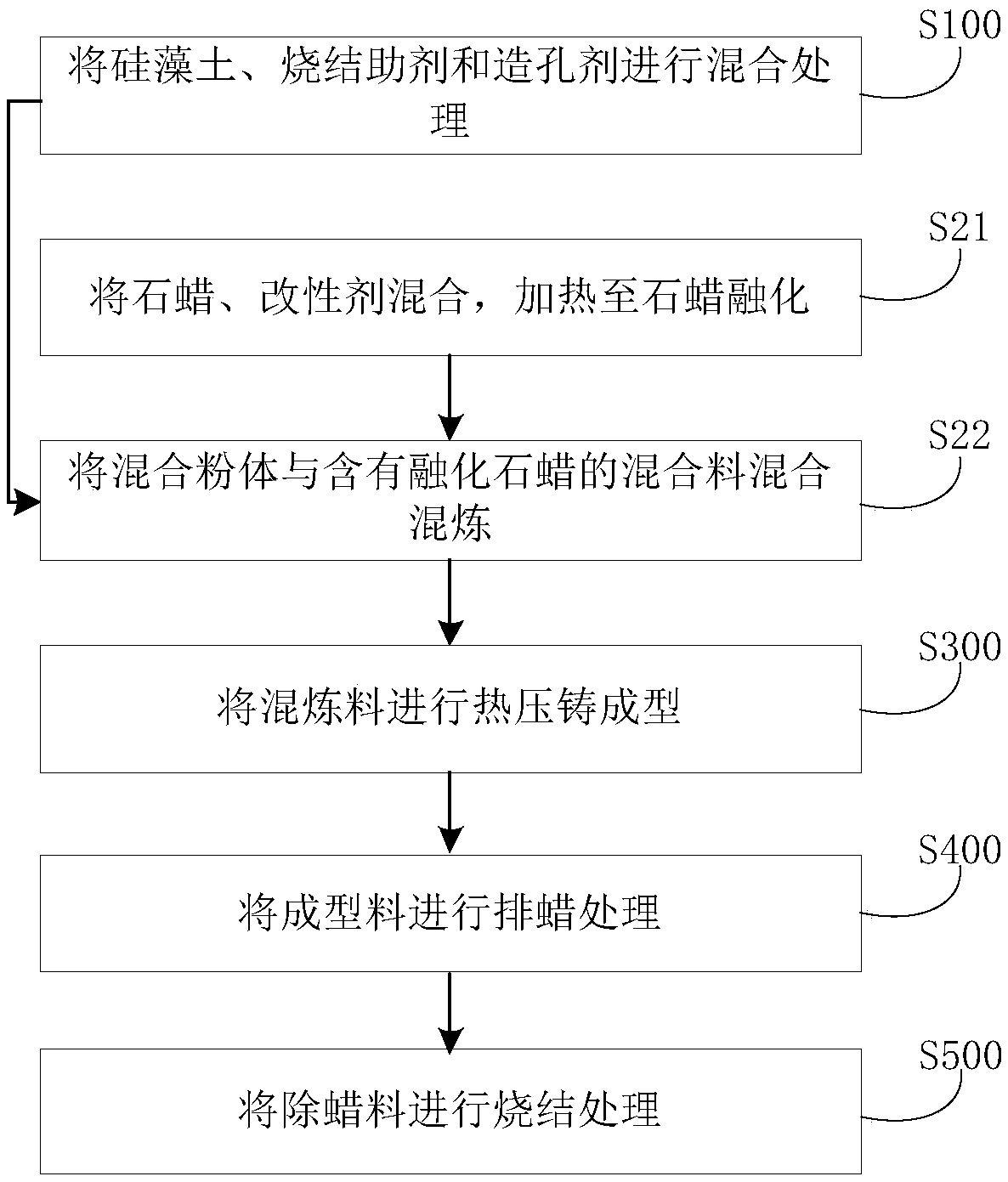

[0053] In one aspect of the present invention, the present invention proposes a preparation method of diatomite-based porous ceramics, according to the embodiments of the present invention, refer to figure 1 , the method includes:

[0054] S100: Mix diatomaceous earth, sintering aid and pore-forming agent

[0055] In this step, the diatomite, sintering aid and pore-forming agent are mixed to obtain a mixed powder. The inventors found that by mixing diatomite with sintering aids and pore-forming agents, it is beneficial to increase the contact area between diatomite, sintering aids, and pore-forming agents, thereby improving subsequent mixing efficiency and mixing effect. The sintering aid will form a liquid phase at high temperature, which can reduce the sintering temperature of porous ceramics; the pore-forming agent will volatilize at high temperature sintering, thereby leaving corresponding pores in the ceramic.

[0056] According to an embodiment of the present invention...

Embodiment 1

[0101] Diatomaceous earth, low-temperature and heavy metal-free glass powder (particle size is 1500 mesh, melting temperature is 650-750°C) and polystyrene microspheres (particle size is 20 μm) are supplied to the Mix in a ball mill to obtain a mixed powder; supply the paraffin and stearic acid to the wax mixer according to 25wt%: 5wt% for mixing, and heat until the paraffin melts to obtain a mixture containing melted paraffin; supply the mixed powder to the mixer Mix and knead with the mixture containing melted paraffin in the wax machine to obtain the mixture; hot die-cast the mixture at 70°C and 3MPa pressure to obtain the molding material; supply the molding material to the wax discharge furnace Carry out wax removal treatment, the temperature of wax removal treatment is 300 ℃, the temperature rise rate of wax removal treatment is 0.5 ℃ / min when it is below 200 ℃, and the temperature rise rate of wax removal treatment is 1 ℃ / min when it is above 200 ℃, in order to obtain D...

Embodiment 2

[0103] Diatomaceous earth, low-temperature and heavy metal-free glass powder (particle size is 2000 mesh, melting temperature is 750-850 ° C) and polymethyl methacrylate microspheres (particle size is 15 μ m) according to 55wt%: 5wt%: 10wt % is supplied to a ball mill for mixing to obtain a mixed powder; paraffin and stearic acid are supplied to a wax mixer according to 27wt%: 3wt% for mixing, and heated until the paraffin melts to obtain a mixture containing melted paraffin; the mixed powder Supply to the wax mixer and mix and knead with the mixture containing melted paraffin to obtain the mixture; hot die-cast the mixture at 70°C and 3MPa pressure to obtain the molding material; supply the molding material to The wax removal furnace performs wax removal treatment. The temperature of the wax removal treatment is 300°C. The temperature rise rate of the wax removal treatment is 0.5°C / min when the temperature is below 200°C, and the temperature rise rate of the wax removal treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap