A kind of organic/inorganic hybrid cationic anti-phase demulsifier and its preparation method and application

An inverse demulsifier and cation technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of reducing oil-water interfacial film tension, oil sludge coagulation, high cation degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

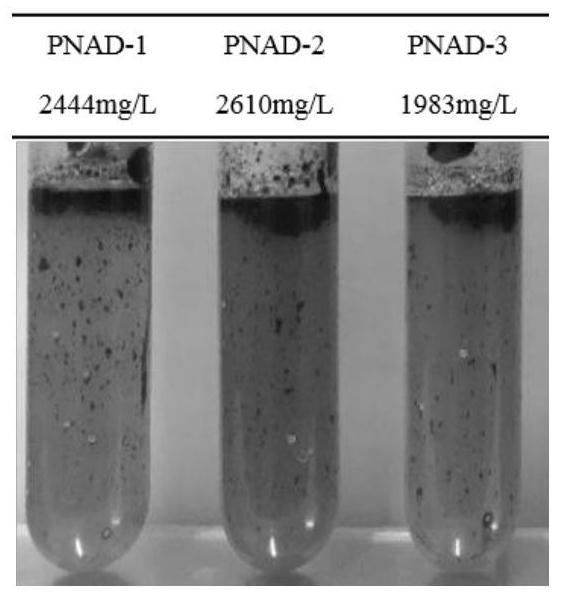

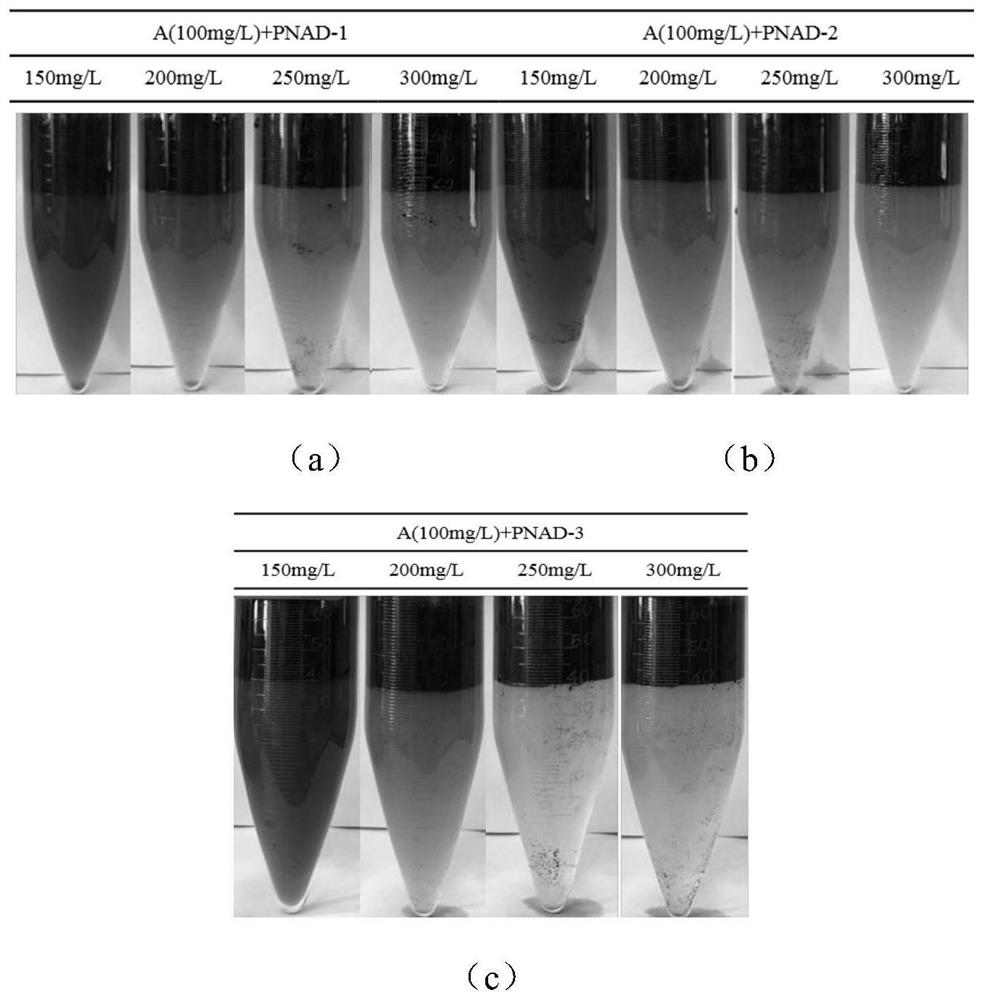

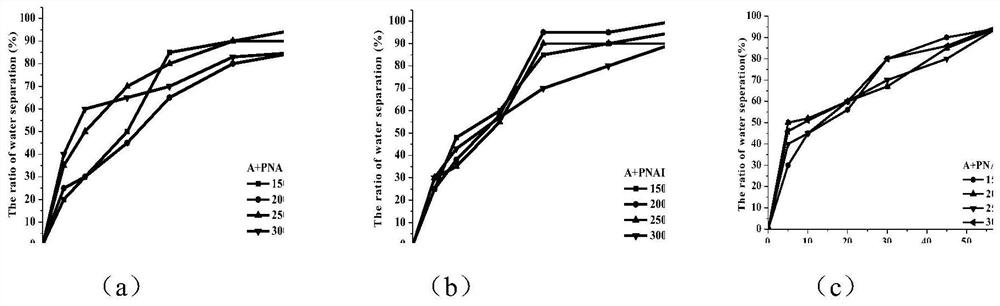

[0052] Embodiment 1, preparation of organic / inorganic hybrid cationic inverse demulsifier PNAD-1

[0053] (1) Weigh 2g nano-SiO 2 In a 100ml Erlenmeyer flask, use 80ml of 0.05mol / L NaOH solution to stir for 24h under sealed conditions to make it fully dispersed in the alkali solution, centrifuge to obtain a C ml solution (≈80mL), measure from the separated CmL solution Take 10mL, and then use 0.05mol / L HCl to titrate 10ml of C solution to neutrality, record the consumption of HCl solution as A ml, and finally use HCl solution to titrate the remaining solution (C-10)mL, the consumption of HCl solution Record B ml, and finally according to the formula: Finally, the surface content of silanol was calculated to be 5.35mmol / g;

[0054] (2) 5g nano-SiO 2 Uniformly dispersed in the mixed solvent of ethanol and water 70ml (V (水 / 乙醇) = 3), and use 2mol / L HCl solution to adjust the pH to 4 for 30 minutes, and place it on a magnetic stirrer every 5 minutes to stir for 1 minute to fin...

Embodiment 2

[0064] Embodiment 2, preparation of organic / inorganic hybrid cationic inverse demulsifier PNAD-2

[0065] (1) Weigh 2g nano-SiO 2 In a 100ml Erlenmeyer flask, use 80ml of 0.05mol / L NaOH solution to stir for 24 hours under sealed conditions to make it fully dispersed in the alkali solution, centrifuge to obtain a C ml solution, and then use 0.05mol / L HCl to 10ml of C The solution is titrated to neutrality, and the consumption is recorded as A ml. Finally, the (C-10) ml solution is titrated with HCl solution, and the consumption is recorded as B ml. Finally, according to the formula: Finally, the calculated silanol surface content is 5.25mmol / g;

[0066] (2) 5g nano-SiO 2 Uniformly dispersed in the mixed solvent of ethanol and water 70ml (V (水 / 乙醇) = 3), and use 2mol / L HCl solution to adjust the pH to 4 for 30 minutes, and place it on a magnetic stirrer every 5 minutes to stir for 1 minute to finally obtain uniformly dispersed nano-SiO 2 70ml solution containing 5g nano-SiO ...

Embodiment 3

[0076] Embodiment 3, preparation of organic / inorganic hybrid cationic inverse demulsifier PNAD-3

[0077] (1) Weigh 2g nano-SiO 2 In a 100ml Erlenmeyer flask, use 80ml of 0.05mol / L NaOH solution to stir for 24 hours under sealed conditions to make it fully dispersed in the alkali solution, centrifuge to obtain a C ml solution, and then use 0.05mol / L HCl to 10ml of C The solution is titrated to neutrality, and the consumption is recorded as A ml. Finally, the (C-10) ml solution is titrated with HCl solution, and the consumption is recorded as B ml. Finally, according to the formula: Finally, the surface content of silanol was calculated to be 5.35mmol / g;

[0078] (2) 5g nano-SiO 2 Uniformly dispersed in the mixed solvent of ethanol and water 70ml (V (水 / 乙醇) = 3), and use 2mol / L HCl solution to adjust the pH to 4 for 30 minutes, and place it on a magnetic stirrer every 5 minutes to stir for 1 minute to finally obtain uniformly dispersed nano-SiO 2 70ml solution containing 5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com