Graphene oxide film/poly-4-vinyl pyridine/porous three-dimensional flower-shaped micron silver composite material preparation method

A vinylpyridine, graphene film technology, applied in chemical instruments and methods, analytical materials, material excitation analysis, etc., can solve problems such as morphology and structure control, and achieve the effect of trace detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

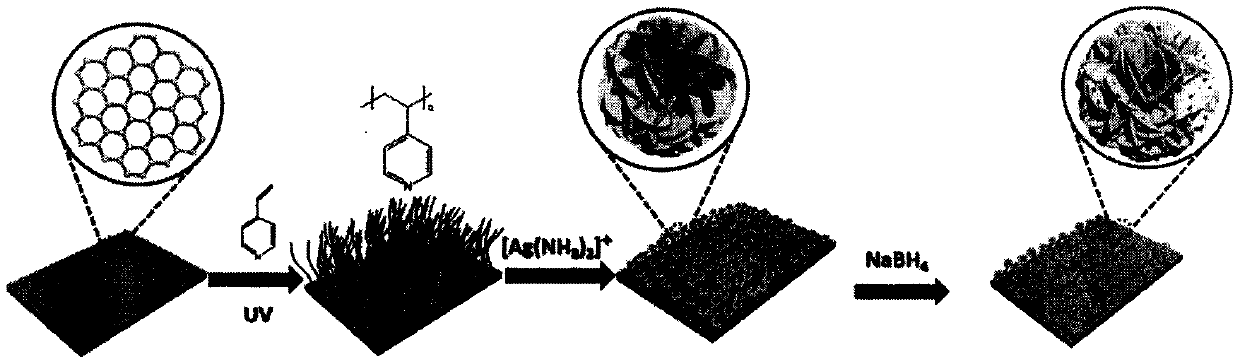

[0015] The present invention relates to a preparation method of graphene oxide film / poly4-vinylpyridine / porous three-dimensional flower-like micron silver composite material, which includes step 1, step 2, and step 3.

[0016] Step 1: Drop the ethanol solution of graphene oxide (GO) on the silica gel stamp, transfer the GO to the substrate using the stamp imprint transfer method, and obtain the GO film after the ethanol is volatilized;

[0017] Step 2: Immerse the obtained GO film into a sealed tube containing 4-vinylpyridine (4VP) monomer, fill it with nitrogen, and irradiate it with ultraviolet light for 30 to 180 minutes. After the reaction, the GO film is taken out and rinsed to obtain the GO film / P4VP;

[0018] Step 3: Soak the obtained GO membrane / P4VP directly into the silver ammonia solution for 10min~12h, then take out the GO membrane / P4VP and directly soak into NaBH 4 In the aqueous solution for 30 minutes to 2 hours, take it out for cleaning to obtain a graphene oxide fil...

Embodiment 1

[0028] The schematic diagram of the preparation of graphene oxide film / poly4-vinylpyridine / porous three-dimensional flower-like micron silver composite material is as follows figure 1 Shown.

[0029] Step 1: Disperse graphene oxide in an ethanol solution ultrasonically, and prepare an ethanol solution of 0.05 mg / mL graphene oxide. Drop the ethanol solution of graphene oxide on the silica gel stamp, transfer GO to the silicon wafer using the stamp imprint transfer method, and naturally dry to remove the ethanol to obtain the GO film.

[0030] Step 2: Immerse the obtained GO film into a sealed tube containing 4-vinylpyridine (4VP) monomer, fill it with nitrogen, and irradiate it with ultraviolet light with a wavelength of 350nm for 4 hours at room temperature. After the reaction, the GO film is taken out and used Chloroform rinses to remove the P4VP polymer that has not been grafted onto the GO surface to obtain GO membrane / P4VP.

[0031] Step 3: Soak the obtained GO membrane / P4VP dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com